Manufacturing method of three-dimensional memory and three-dimensional memory

A manufacturing method and memory technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The invention provides a method for manufacturing a three-dimensional memory, such as Figure 6 As shown, it includes the steps:

[0064] S1. Provide a substrate structure 1, define an array region 102 and edge regions 101, 103 in the substrate structure 1, the array region 102 includes a core region 1022 and step regions 1021, 1023;

[0065] S2, the semiconductor layer 12 on the substrate structure 1;

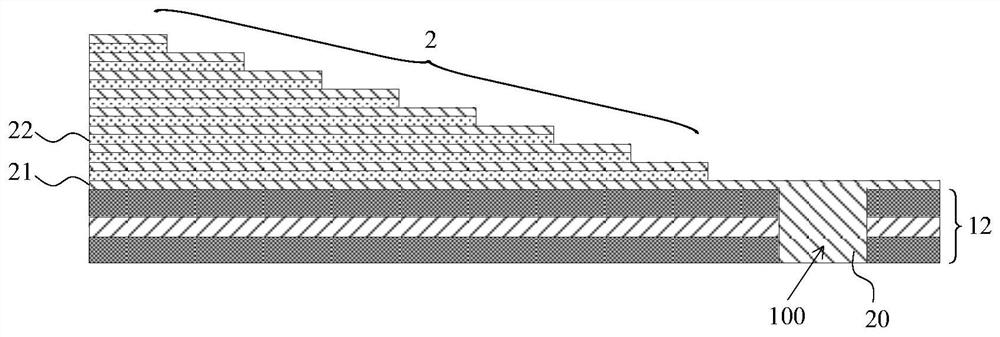

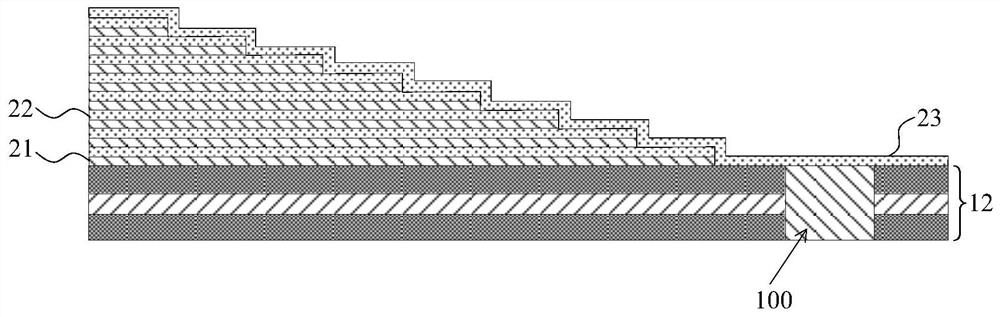

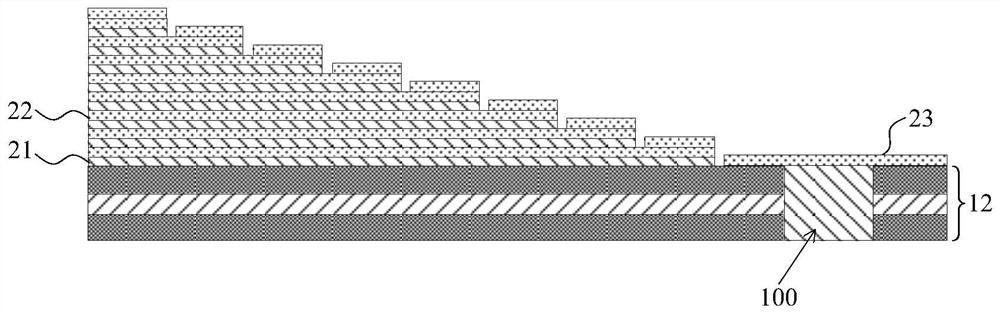

[0066] S3, forming a via hole 100 penetrating through the semiconductor layer 12 on the edge regions 101, 103, and filling the via hole 100 with the first dielectric layer 20;

[0067] S4, forming a stack structure 2' on the semiconductor layer 12 in the array region 102, the stack structure 2' comprising alternately stacked second dielectric layers 21 and dummy gate layers 22;

[0068] S5. Etching the stack structure 2' to form a step structure 2 on the step regions 1021 and 1023, the step structure 2 includes multiple steps 2a, and each step 2a includes a second die...

Embodiment 2

[0121] In Embodiment 1 of the present invention, as Figure 21 As shown, the etching of the first contact hole 200 stays on the dummy gate covering layer 23, that is, the first contact hole 200 does not pass through the dummy gate covering layer 23, but the etching of the corresponding third contact hole 500 is too much. etching; such as Figure 24 As shown, the second contact hole 400 and the third contact hole 500 are formed by simultaneous etching. After the fourth dielectric layer 26 is etched through, the semiconductor layer 12 needs to be used to fill the first dielectric in the first contact hole 200. The high selectivity ratio of layer 20 is achieved.

[0122]However, this has requirements on the material of the semiconductor layer 12 and the first dielectric layer 20 filled in the first contact hole 200 , and the etching depth of the corresponding second contact hole 400 is relatively deep, and the process conditions are relatively harsh.

[0123] Based on this, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com