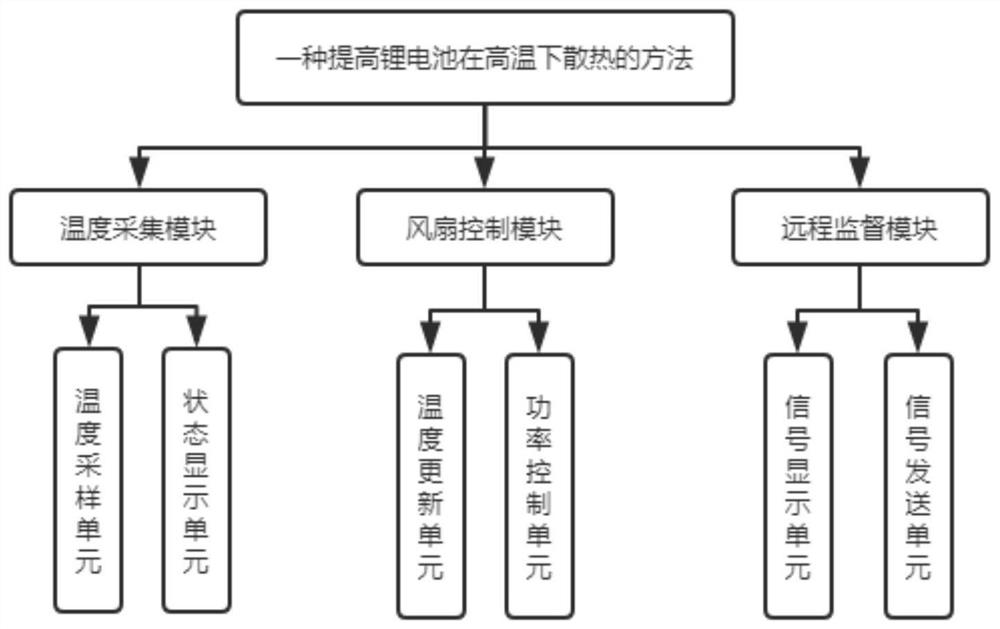

A method for improving the heat dissipation of lithium batteries at high temperatures

A lithium battery, battery technology, applied in the direction of secondary battery, secondary battery repair/maintenance, secondary battery charging/discharging, etc., can solve the problems of shortening the service life of the battery pack, unable to enhance the air flow rate, and increasing the effect of heat dissipation. , to achieve the effect of increasing air flow, increasing air heat exchange and cooling effect, and enhancing air circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

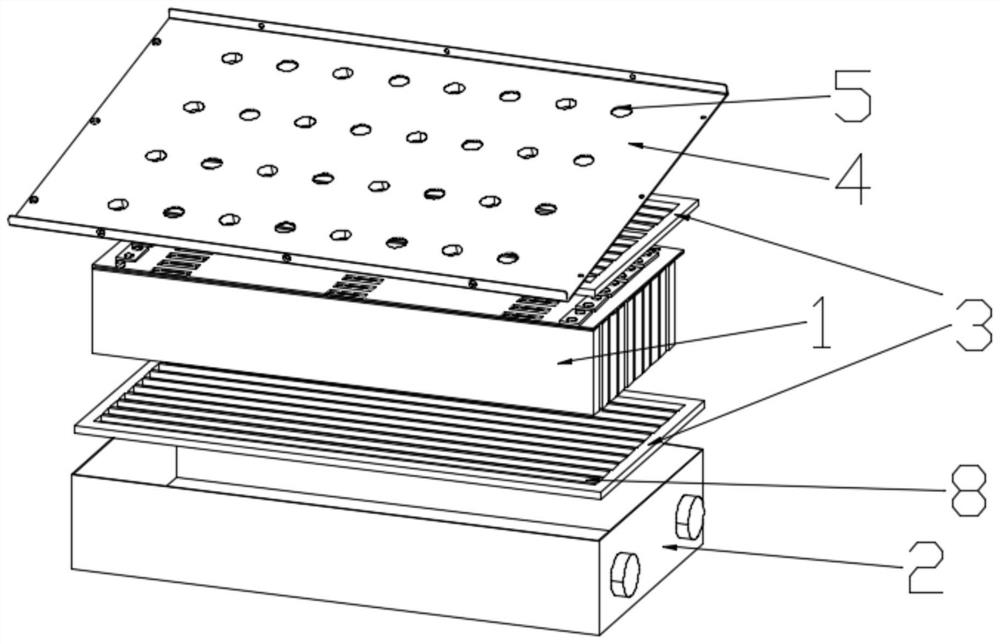

Examples

Embodiment 1

[0063] Embodiment 1: In the step S3, the temperature inside the battery is T, the power of the fan is Q, and the curve of power and temperature is fitted using MATLAB instructions and the linear least square method, and the corresponding temperature and fan The power value is as follows:

[0064] Ti 35 40 26 24.5 37.3 Qi 15 20 14 10 17

[0065] According to the formula:

[0066] f(q)=α 1 t 2 +α 2 t+α 3 ;

[0067] Using MATLAB instructions:

[0068] X=20:20.1:50;

[0069] Y=[1014151720];

[0070] R=[(X.^2)'X'ones(5,1)];

[0071] α=R / Y';

[0072] Get the calculation result: α 1 =22.302,α 2 = 31.407, α 3 =-6.318;

[0073] f(q)=22.302t 2 +31.407t-6.318;

[0074] According to the above summary, the existing data is stored in the database, and the data in the database is used for linear quadratic fitting. Through the above function, the battery pack fan 2 can be controlled according to the measured temperature of the battery pack 1 Rapid...

Embodiment 2

[0075] Embodiment 2: The following uses the preset temperature of 46°C as an example to describe the present invention in detail:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com