Cable head manufacturing platform

A technology for making platforms and cable heads, applied in the direction of connecting/terminating cables, etc., can solve the problems of high physical exertion, reduced labor intensity, low efficiency, etc., and achieve the effect of reducing labor intensity, improving efficiency, and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

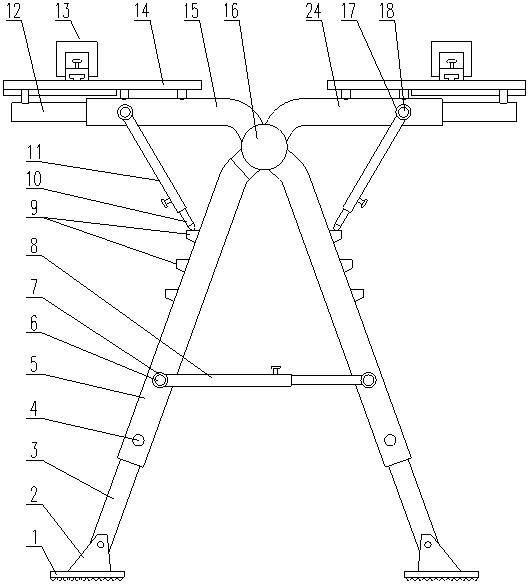

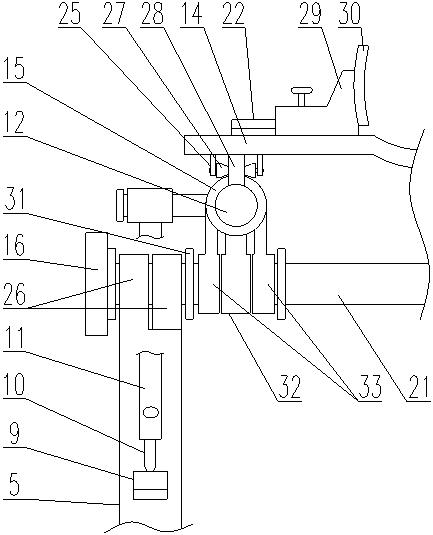

[0020] Such as Figure 1-4 As shown, a cable head manufacturing platform includes a central rod 21, the left end and the right end of the central rod 21 are connected with two primary legs 5 through a leg ring 26, and the leg ring 26 The connection with the primary leg 5 is arc-shaped, the secondary leg 3 is slidably connected to the inside of the primary leg 5, and the end of the secondary leg 3 is rotatably connected to a connecting gusset 2. The connecting gusset 2 is connected with the footboard 1; the side of the lower part of the primary leg 5 is provided with a first short rod 6, and the first short rod 6 is rotatably connected with a first connecting pipe 7, and the adjacent two A first tie rod 8 is connected between the first connecting pipes 7; a second connecting pipe 19 is provided on the side of the middle part of the primary leg 5, and a second connecting pipe 19 is connected between two adjacent second connecting pipes 19. Tie rod 20; the left end and the right...

Embodiment 2

[0023] Such as Figure 1-4As shown, a cable head manufacturing platform includes a central rod 21, the left end and the right end of the central rod 21 are connected with two primary legs 5 through a leg ring 26, and the leg ring 26 The connection with the primary leg 5 is arc-shaped, the secondary leg 3 is slidably connected to the inside of the primary leg 5, and the end of the secondary leg 3 is rotatably connected to a connecting gusset 2. The connecting gusset 2 is connected with the footboard 1; the side of the lower part of the primary leg 5 is provided with a first short rod 6, and the first short rod 6 is rotatably connected with a first connecting pipe 7, and the adjacent two A first tie rod 8 is connected between the first connecting pipes 7; a second connecting pipe 19 is provided on the side of the middle part of the primary leg 5, and a second connecting pipe 19 is connected between two adjacent second connecting pipes 19. Tie rod 20; the left end and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com