Eccentric rotary grinding induction cooker heating type medicine decocting method and medicine decocting device

A technology of eccentric rotation and decoction method, which is applied in heating methods, electric heating fuel, and devices for making medicines into special physical or taking forms, etc. , to achieve the effect of not easily damaged and accelerated frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

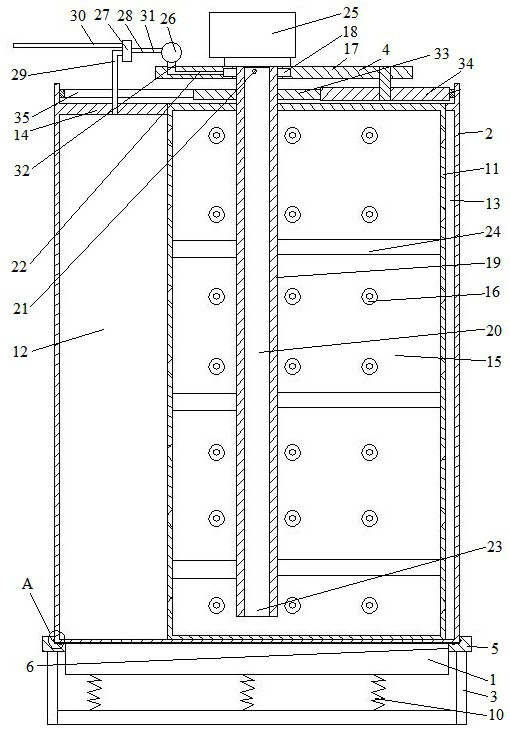

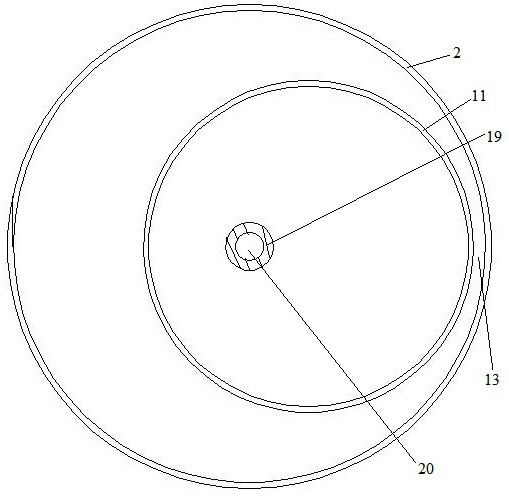

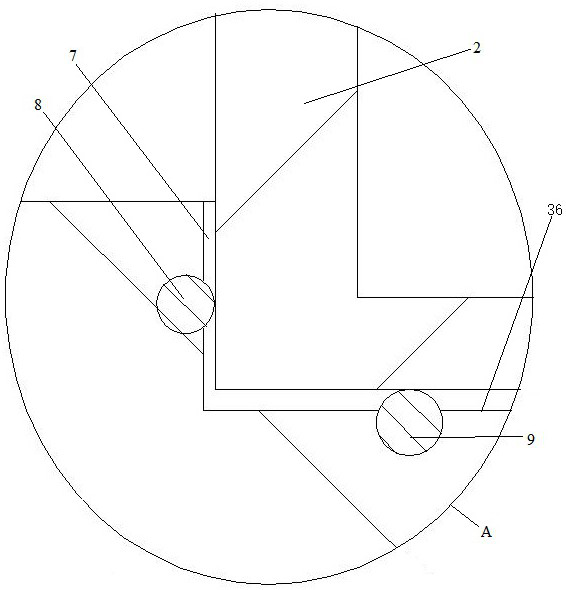

[0024] Such as Figures 1 to 3, an eccentric rolling rolling electromagnetic furnace heating type decoction device, including an induction cooker 1, a circular decoction barrel 2, a bottom frame 3 and a top frame 4. The bottom frame and top frame are fixed together. The bottom frame is provided with a panel 5 . The panel is provided with an induction cooker accommodating hole 6 . The upper end of the accommodating hole of the induction cooker is provided with a large-diameter section 7 . A decoction barrel support step 36 is formed between the large-diameter section and the accommodating hole of the electromagnetic oven, and the decoction barrel support step constitutes a medicine barrel support portion for supporting the medicine barrel. The large-diameter section is provided with some supporting rolling balls 8 distributed along the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com