Rapid cleaning sand screening machine

A kind of sand screening machine, fast technology, applied in the field of sand screening machine, can solve the problems of inconvenient feeding, inability to carry out continuous sand screening operation, affecting sand screening efficiency, etc., and achieve the effect of small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

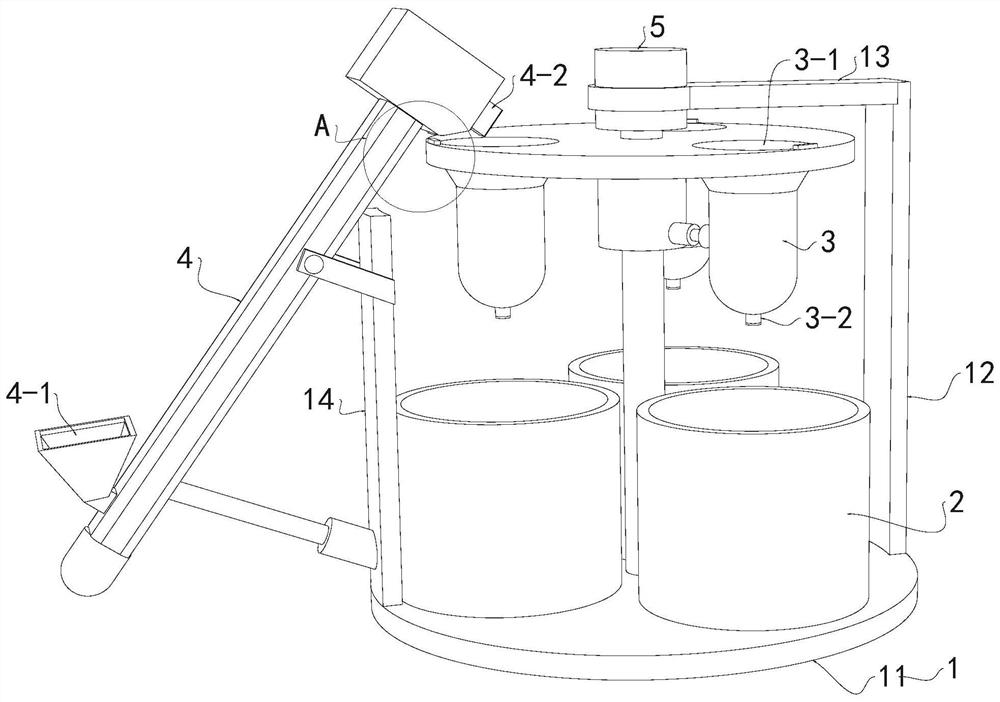

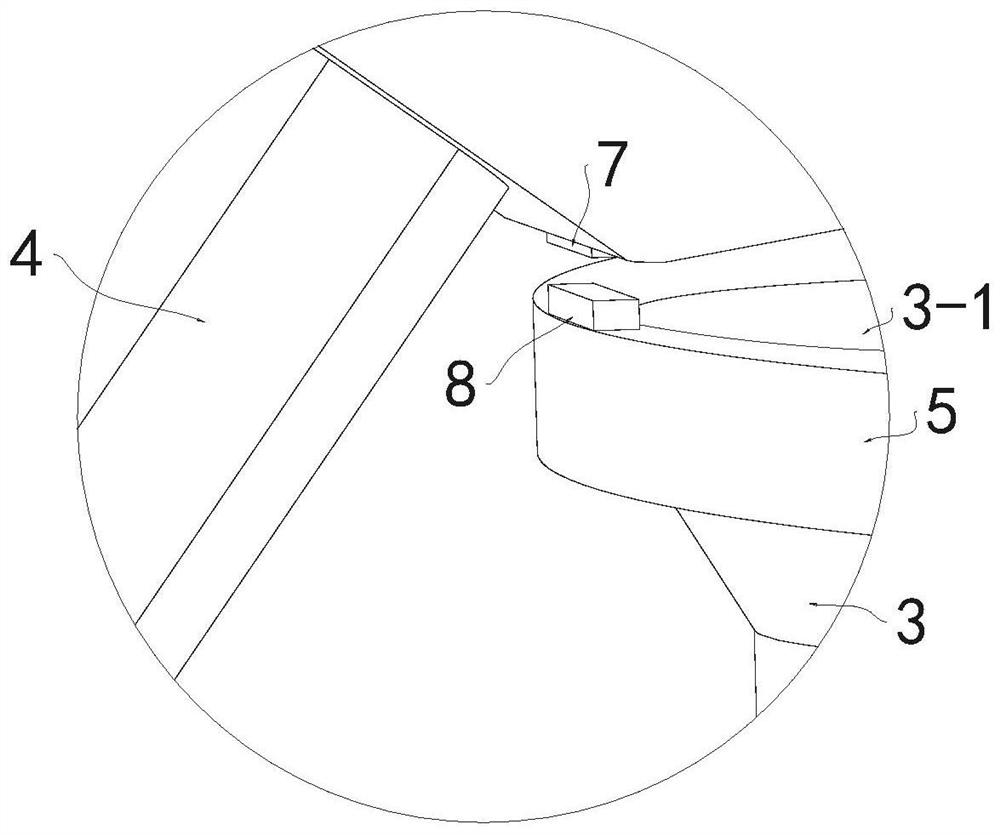

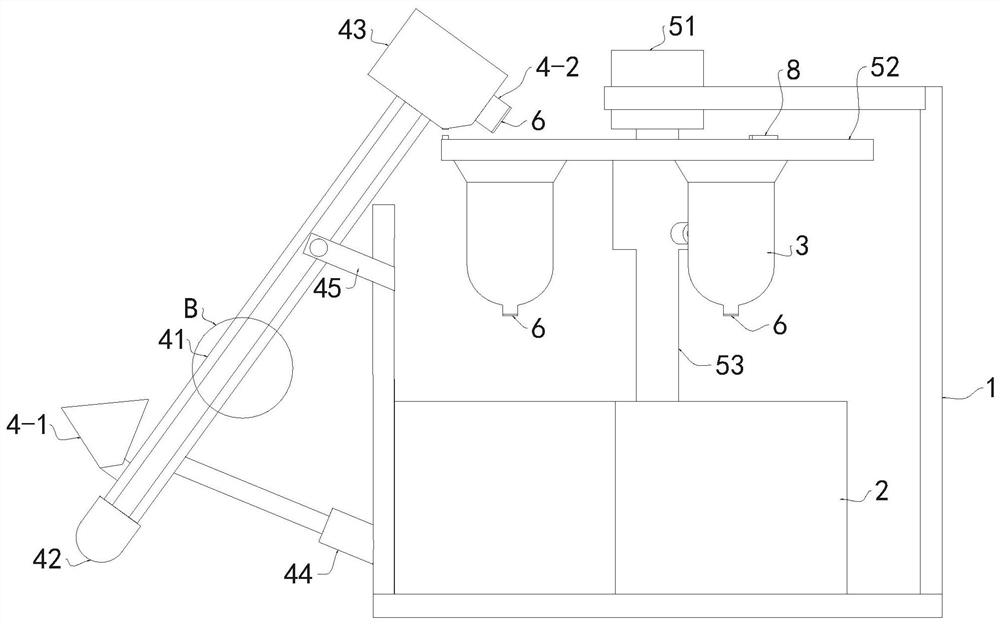

[0043] see Figure 1-12 , a quick-cleaning sand screening machine, comprising a frame 1, a material receiving box 2, a sand bag 3, a feeding assembly 4 and a sand screening system; the number of sand bags 3 is at least 2, and the sand bags 3 are equidistantly distributed inside the frame 1 , the upper and lower ends of the sand pocket 3 are respectively provided with a feed port 3-1 and a miscellaneous discharge port 3-2, the feed port 3-1 is used for sand feeding, and the miscellaneous discharge port 3-2 is used for discharge; the receiving box 2 Corresponding to the number of sand pockets 3, located below the sand pockets 3, and placed on the frame 1 in a circular manner, used to accept sand or impurities leaked from the miscellaneous discharge port 3-2; the feeding component 4 is installed on the frame 1 , used to add sand to the sand pocket 3, the two ends of the feeding assembly 4 are respectively provided with a sand inlet 4-1 and a sand outlet 4-2, the sand outlet 4-2 i...

Embodiment 2

[0055] see Figure 9 , different from Embodiment 1, the energization structure 541 includes a energization coil 54b, the energization coil 54b is installed in the column 53 and is close to the upper spline sleeve 544, and the middle sleeve 543 is inside the energization coil 54b, when the energization coil 54b is energized At this time, the middle sleeve 543 generates an attractive force and moves up to be inserted into the upper spline sleeve 544; when the electromagnet 54a1 is turned off, the attractive force disappears, and the middle sleeve 543 returns to its position under the action of gravity and is inserted into the lower spline Inside the sleeve 542.

[0056] When working, by energizing the energized coil 54b, the energized coil 54b has an upward suction force on the middle sleeve 543, so that the middle sleeve 543 is snapped into the upper spline sleeve 544. After the power is turned off, the middle sleeve 543 will Snap into the lower spline sleeve 542.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap