Centering alloy tool bit twist drill

A technology of centering alloy and alloy knives, which is applied in twist drills, drill repairing, drilling tool accessories, etc., can solve the problems of easy damage of cutting edges, low efficiency of cutting tools, and non-absolute balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

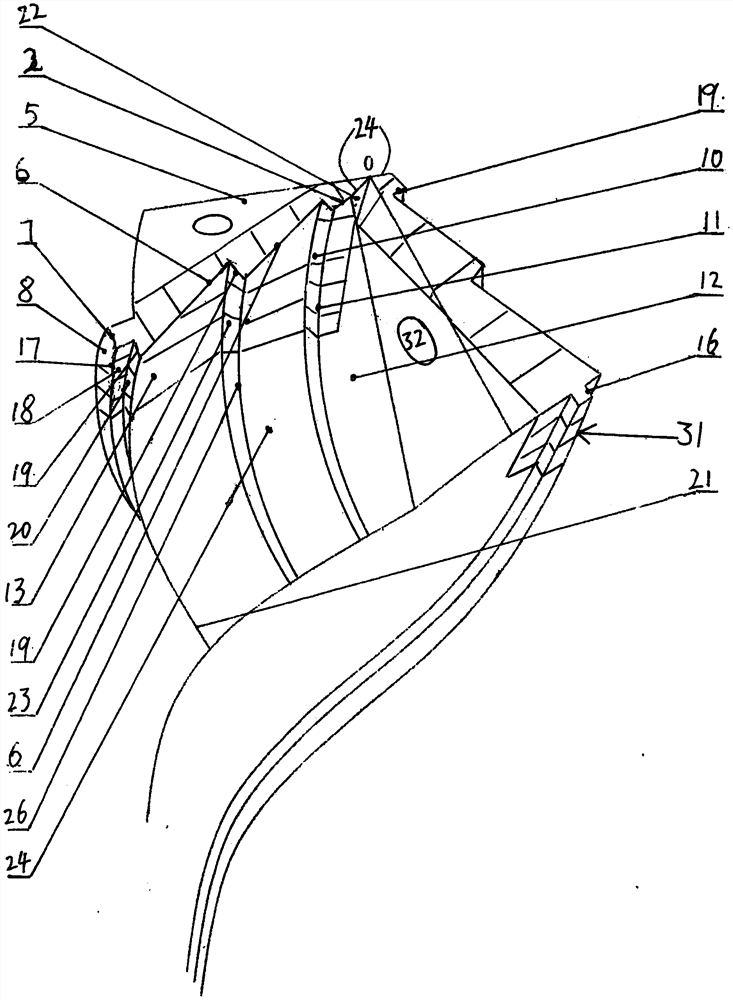

[0037] Such as Figure 1-2 As shown, the centering alloy cutter head twist drill 1 of the first embodiment of the present invention, the centering alloy cutter head twist drill 1 mainly relates to drilling tools for machining, and the centering alloy cutter head twist drill The integral one consists of a tool shank (not shown) including a tapered shank or a straight shank, and a helical cutter body 4. At least two helical cutter bodies 4 are milled on the helical cutting surface at the front end and integrally or connected and formed integrally. There is an alloy cutter head 31, and the alloy cutter head 31 is integrally formed with a cutting surface 13 facing the front end of the rotation direction along the axial center of the centering alloy cutter head twist drill 1, and two helical cutter bodies 4 integrally arranged The helical cutting surfaces 13 on both sides of the alloy cutter head 31 are respectively provided with the same groove as the two cutting surfaces 13 integ...

Embodiment approach 2

[0047] Such as Figure 1-4 As shown, the centering alloy cutter head twist drill 1 of the first embodiment of the present invention, the centering alloy cutter head twist drill 1 mainly relates to drilling tools for machining, and the centering alloy cutter head twist drill The integral one consists of a tool shank (not shown) including a tapered shank or a straight shank, and a helical cutter body 4. At least two helical cutter bodies 4 are milled on the helical cutting surface at the front end and integrally or connected and formed integrally. There is an alloy cutter head 31, and the alloy cutter head 31 is integrally formed with a cutting surface 13 facing the front end of the rotation direction along the axial center of the centering alloy cutter head twist drill 1, and two helical cutter bodies 4 integrally arranged The helical cutting surfaces 13 on both sides of the alloy cutter head 31 are respectively provided with the same groove as the two cutting surfaces 13 integ...

Embodiment approach 3

[0057] like Figure 1-4 As shown, the centering alloy cutter head twist drill 1 of the first embodiment of the present invention, the centering alloy cutter head twist drill 1 mainly relates to drilling tools for machining, and the centering alloy cutter head twist drill The integral one consists of a tool shank (not shown) including a tapered shank or a straight shank, and a helical cutter body 4. At least two helical cutter bodies 4 are milled on the helical cutting surface at the front end and integrally or connected and formed integrally. There is an alloy cutter head 31, and the alloy cutter head 31 is integrally formed with a cutting surface 13 facing the front end of the rotation direction along the axial center of the centering alloy cutter head twist drill 1, and two helical cutter bodies 4 integrally arranged The helical cutting surfaces 13 on both sides of the alloy cutter head 31 are respectively provided with the same groove as the two cutting surfaces 13 integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com