Multifunctional industrial robot

An industrial robot, multi-functional technology, used in manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve problems such as increased cost, wrong welding position, offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

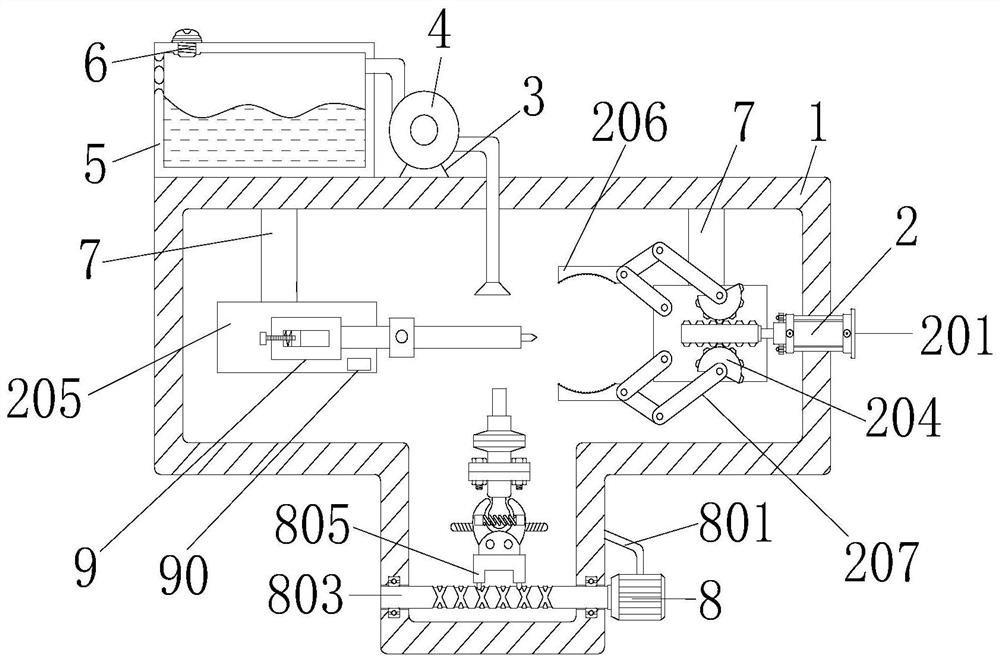

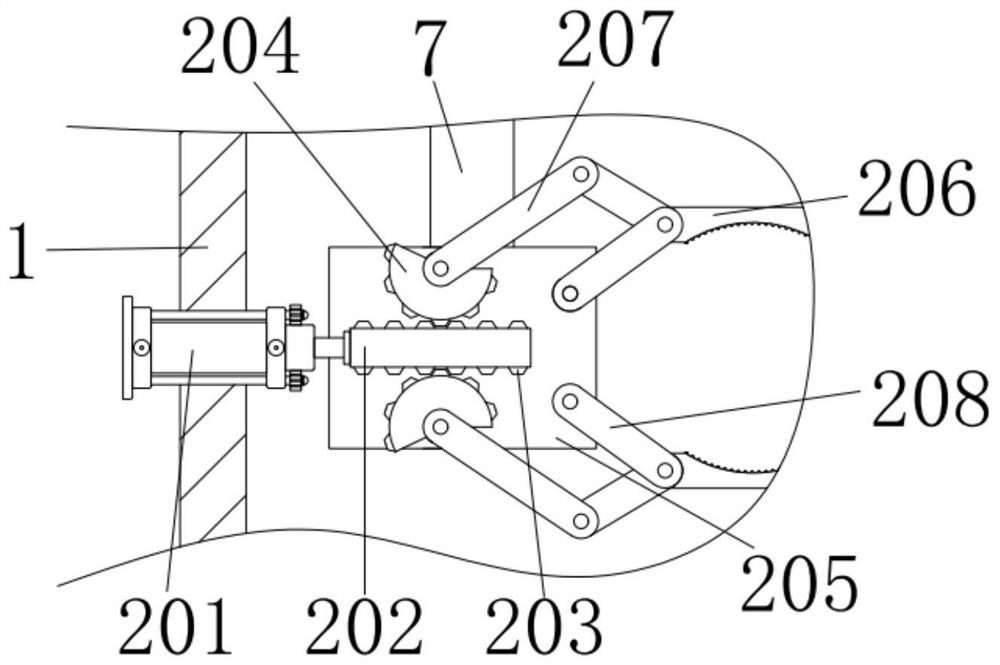

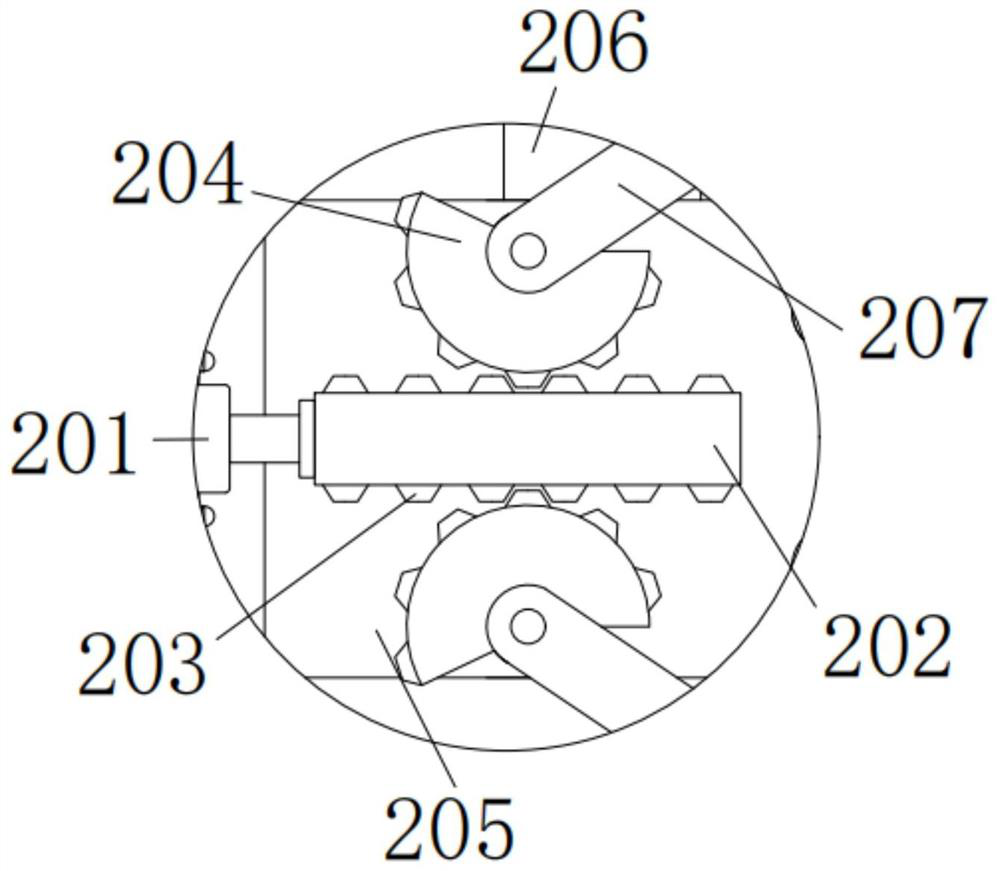

[0037]A multifunctional industrial robot, comprising a shell 1 and a vertical plate 7, two vertical plates 7 are fixedly connected to the left and right sides of the inner wall top of the shell 1, and a positioning device 2 is provided inside the shell 1, and the positioning device 2 includes a hydraulic cylinder 201 , horizontal plate 202, trapezoidal block 203, gear 204, thick plate 205, bent plate 206, first short plate 207 and second short plate 208, the model of hydraulic cylinder 201 is MOB, the outer wall of hydraulic cylinder 201 and the left side of shell 1 The side inner wall is fixedly connected, the internal hydraulic rod of the hydraulic cylinder 201 is fixedly connected with the left end of the horizontal plate 202, the upper and lower sides of the horizontal plate 202 are meshed with the inner walls of the two gears 204 through the trapezoidal block 203, and the horizontal plate 202 drives the trapezoidal block 203 During motion, just can drive gear 204 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com