Self-positioning clamping type packaging box

A self-positioning and packing box technology, which is applied in the direction of transportation and packaging, to prevent mechanical damage, containers, etc., can solve the problems of not having impact resistance, and achieve beautiful appearance, reduce frictional resistance, and scientific and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

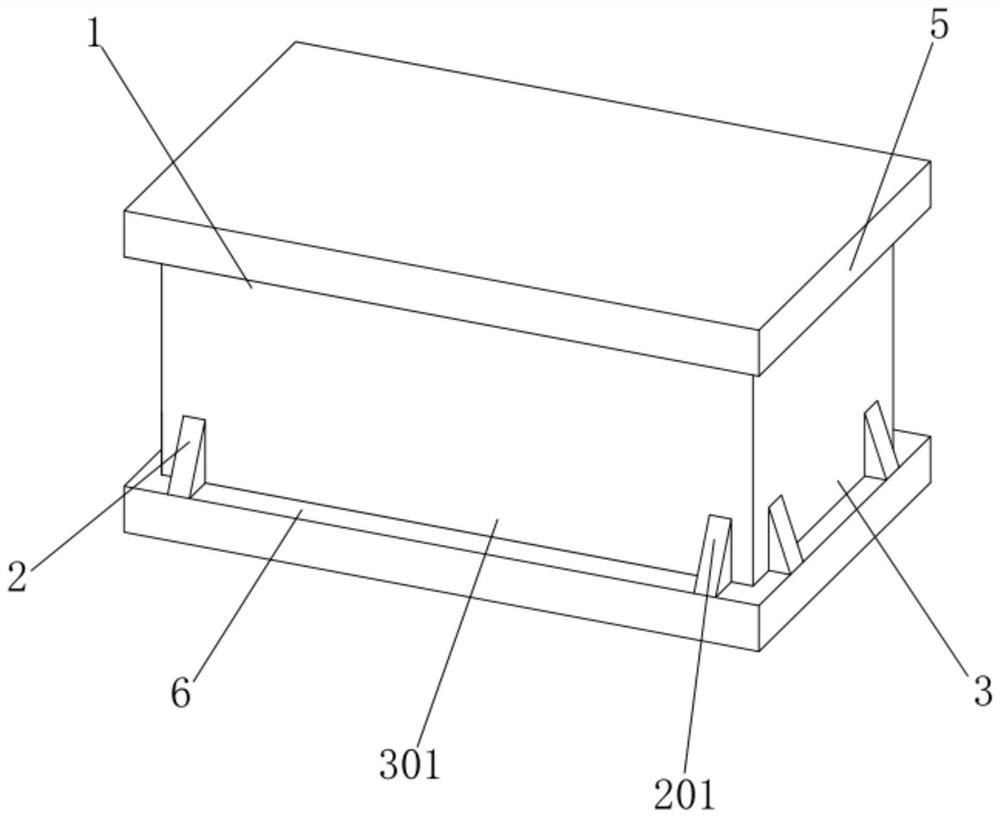

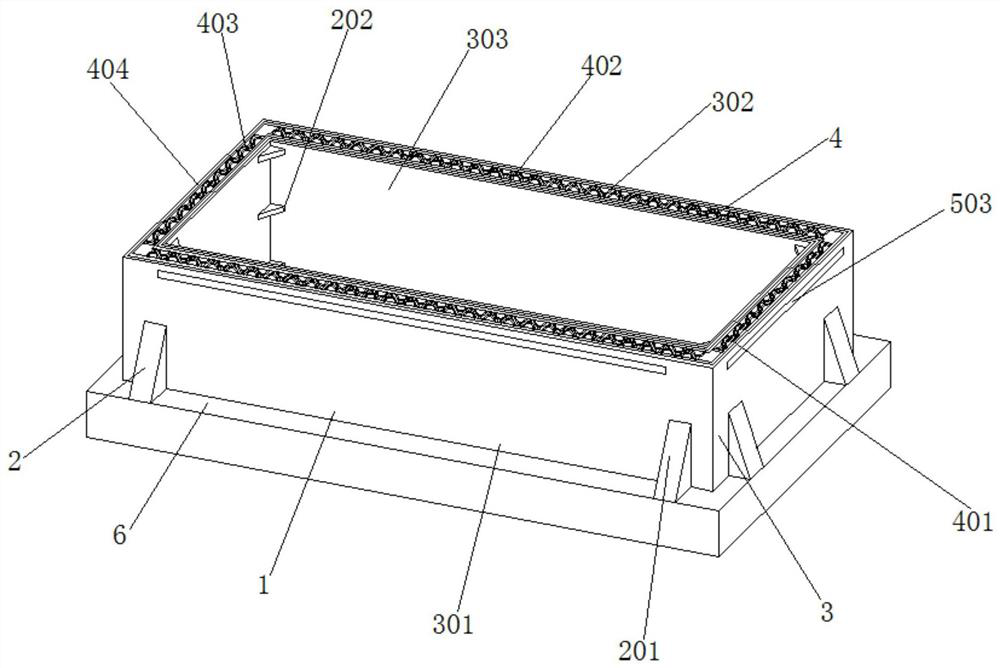

[0040] A self-positioning card and type packaging box, including a box body 1 and a box cover 5, a box cover 5 is placed and fastened above the box body 1, and the center of the inner wall of the box body 1 and the box cover 5 is formed by an anti-collision component 4,

[0041] The middle part of the inner wall of the four sides of the inner cavity of the box cover 5 is provided with a groove 501, and the inner cavity of each group of the grooves 501 is connected with a rotating roller 502, and the outer upper part of the box body 1 is provided with a groove 501. The bar-shaped groove 503, the rotating roller 502 is engaged with the bar-shaped groove 503 movably.

[0042] When opening and closing the box cover, it can play a positioning function, so that the box cover and the box body can be directly connected to each other, and the rotating roller can be connected to the strip groove to play a positioning function. The rotating roller is also made of paper. The box cover is ...

Embodiment 2

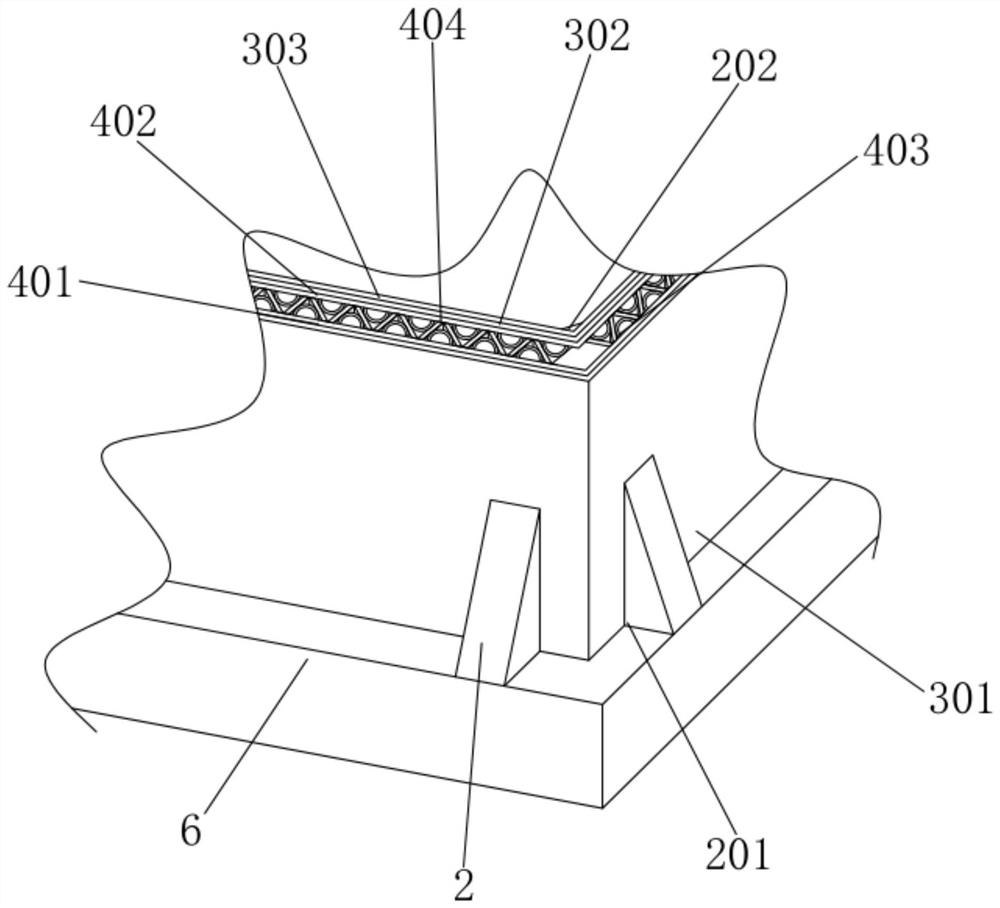

[0045] As an option, see Figure 1-6 , transportation composite anti-collision packaging box, the inner and outer walls of the inner box plate 402 and the outer wall of the outer box plate 401 are installed with a protective component 3, the protective component 3 includes a fireproof coating 301, a shock-absorbing coating 302 and an antifouling coating 303, the shock-absorbing coating 302 and the anti-fouling coating 303 are distributed sequentially from the outside to the inside of the inner inner wall of the inner box plate 402, the shock-absorbing coating 302 is coated on the inner inner wall of the inner box plate 402, and the anti-fouling coating Layer 303 is coated on the inner side inner wall of shock-absorbing coating 302, and fire-proof coating 301 is positioned at the outside outer wall of outer layer box plate 401, and fire-proof coating 301 is coated on the outer wall of outer layer box plate 401, and fire-proof coating 301, shock-absorbing coating The thickness o...

Embodiment 3

[0048] As an option, see Figure 1-3 , transportation composite anti-collision packaging box, the inner wall and the outer wall of the box body 1 are installed with a support assembly 2, the support assembly 2 includes a first support plate 201 and a second support plate 202, and a plurality of first support plates 201 are respectively fixed on The edges and corners below the outer wall of the box body 1 are adjacent to two sides, and a plurality of second support plates 202 are respectively fixed at the four corners of the inner wall of the box body 1, and the second support plates 202 and the inner wall of the box body 1 form an angle of 45 degrees to each other. The first support plate 201 and the second support plate 202 can realize the auxiliary compressive capacity between the sides of the box body 1, the lower end of the box body 1 is fixedly connected with the base 6, and the upper end edge position of the base 6 is all aligned with the first support plate 201 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com