Secant pile water seepage treatment method

A processing method and technology for occlusal piles, which are applied in excavation, construction, infrastructure engineering, etc., can solve the problems of occlusal pile defects, water seepage, loose occlusion, etc., to ensure waterless operation, simple construction method, and solve the problem of occlusal pile water seepage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

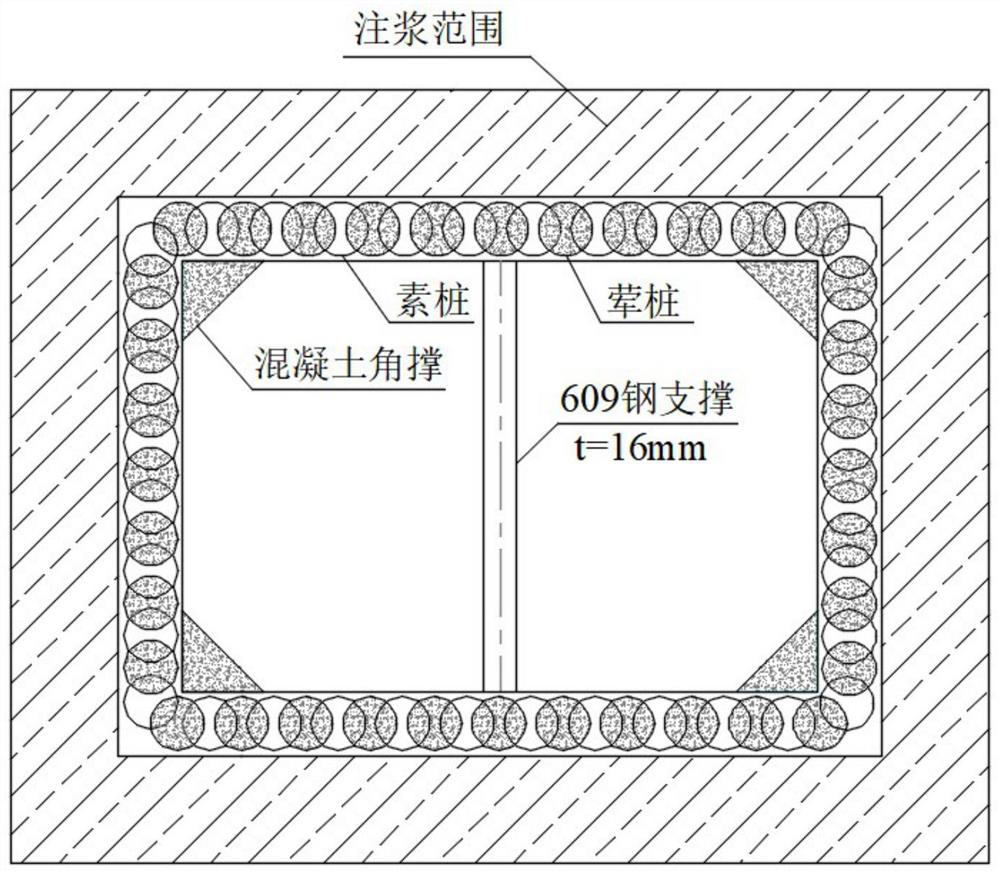

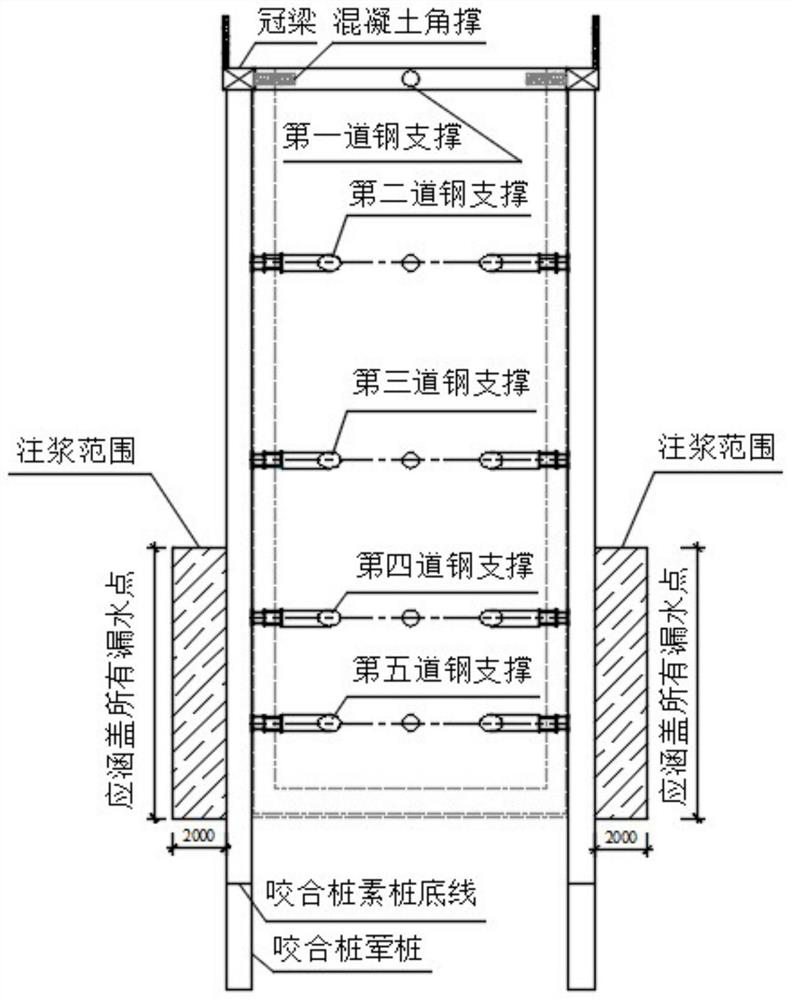

[0024]Such asFigure 1-4As shown, the embodiment of the present invention provides a method for treating water seepage in an occlusal pile, which includes the following steps:

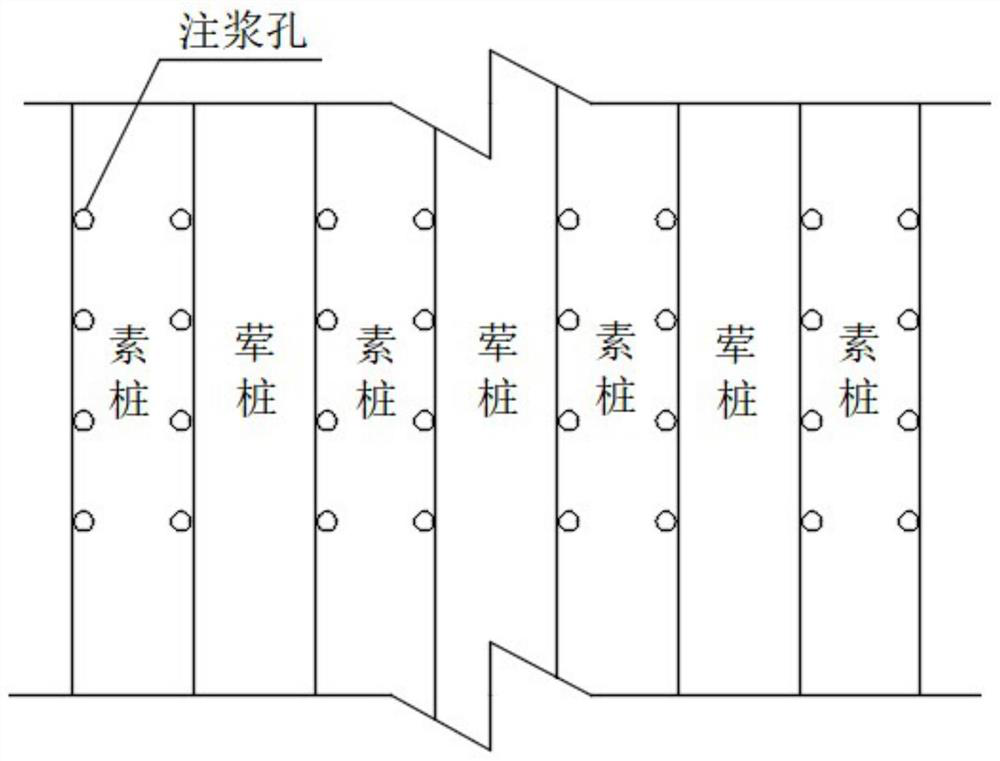

[0025]S1. A number of grouting holes are opened on the occluding piles on the outer side of the shaft wall. The grouting holes pass through the foundation of the occluding piles to the outer end. The lateral spacing between two adjacent holes of the grouting holes is 500-600mm, Vertical distance 500mm, hole depth 2m, such asimage 3 Shown

[0026]S2. Insert a grouting pipe into the inner end of the opened grouting hole. The grouting pipe adopts Ф40 welded steel pipe, and the grouting pipe is arranged on the pile perpendicular to the shaft wall;

[0027]S3. Use a grouting machine to grouting on the outside of the shaft through a grouting pipe. The grouting material is cement-water glass double liquid grout. The grouting plane is around the shaft and is 2m from the outer contour of the occluding pile. The vertical range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com