Pouring device and method for beam-slab-column concrete engineering of different strength grades

A technology of strength grade and concrete, applied in the connection parts of formwork/formwork/work frame, construction, building structure, etc., can solve the problem of heavy workload, lower concrete strength of high strength grade, leakage of basement outer wall, etc. problems, to achieve the effect of enhancing construction quality, facilitating pouring operations, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-4 The application is described in further detail.

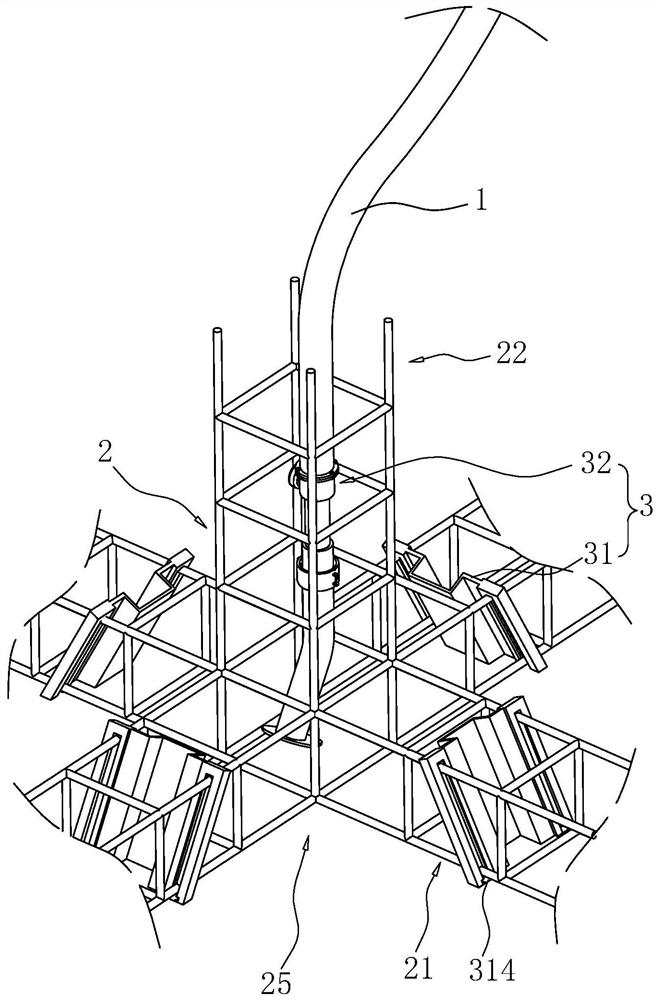

[0043]The embodiment of the present application discloses a pouring device for beam-slab-column concrete works of different strength levels, referring to figure 1 The pouring device 3 includes a baffle 31 installed in the stirrup cage 2, and a pouring tool 32 installed on the discharge port 1 of the concrete placing machine. The pouring tool 32 is used to add concrete to the stirrup cage 2.

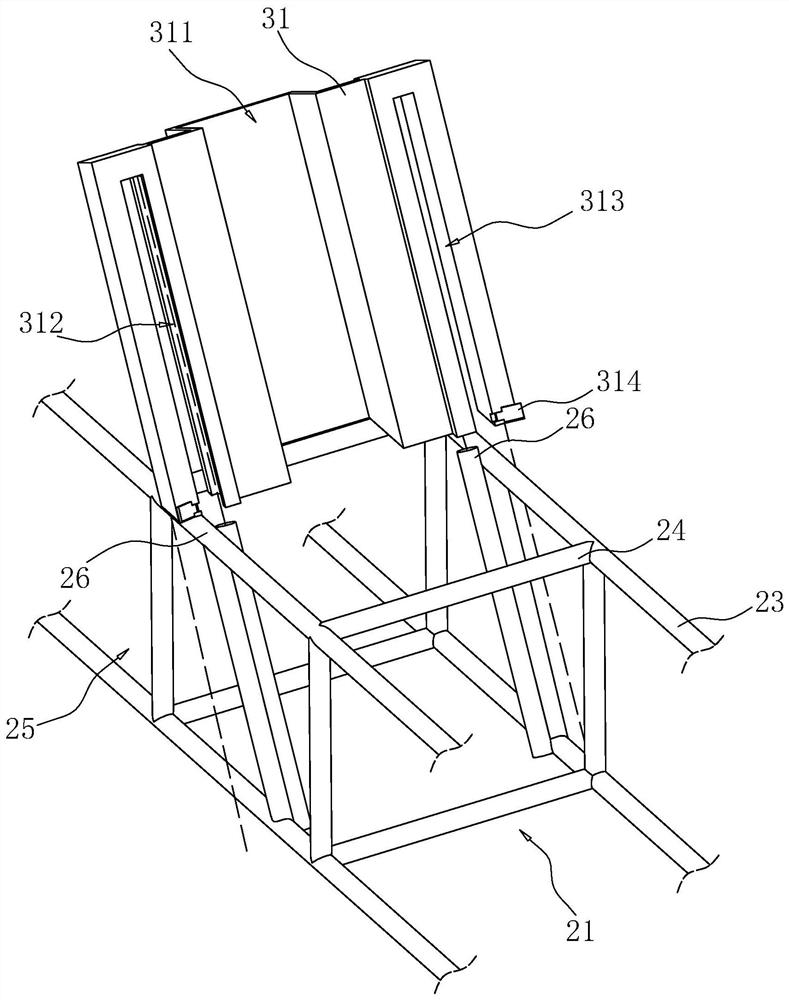

[0044] Stirrup cage 2 comprises beam hoop 21 and column hoop 22, and beam hoop 21 and column hoop 22 are surrounded by a plurality of parallel reinforcing bars 23 and reinforcing bar ring 24, and reinforcing bar ring 24 is fixed on the reinforcing bar 23 at equal intervals, Then the column hoop 22 is vertically inserted into the beam hoop 21 and fixed.

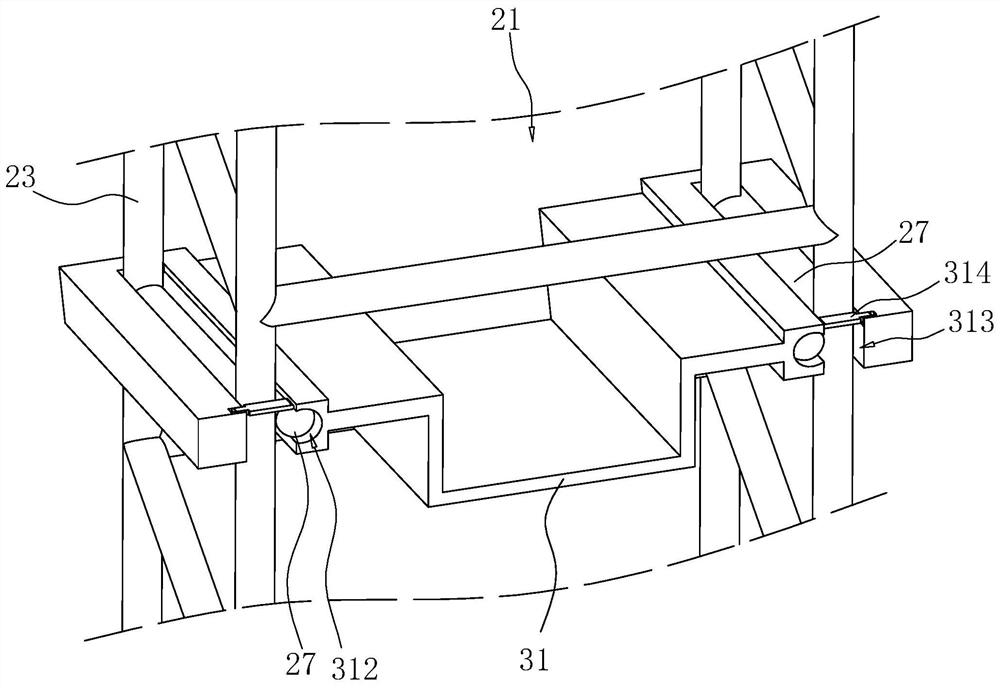

[0045] refer to figure 2 and image 3 A pair of limiting ribs 26 are welded on the inner wall of the beam hoop 21 near the column hoop 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com