Flue gas emission prediction method and system and computer readable storage medium

A technology of flue gas emission and prediction method, which is applied in the direction of computer components, prediction, calculation, etc., can solve the problems of increased cost of flue gas treatment and inability to predict flue gas emission indicators, so as to reduce the cost of flue gas treatment and avoid inaccurate predictions. immediate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

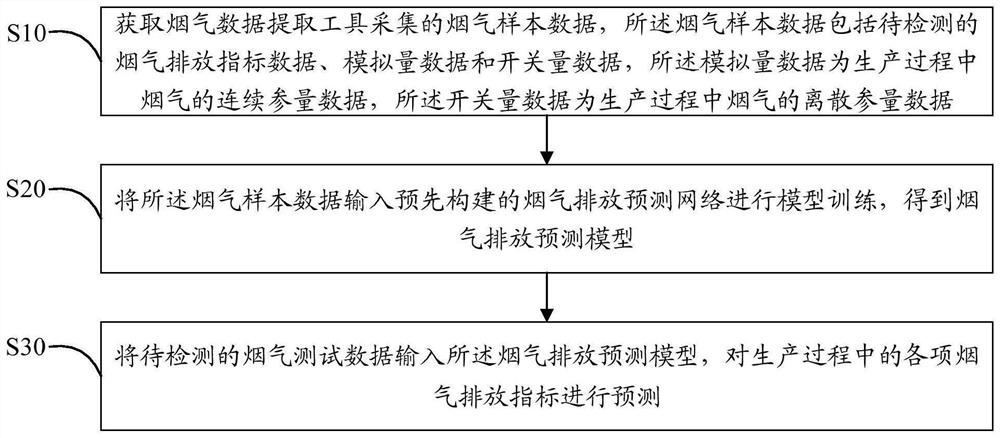

[0080] refer to figure 2 , figure 2 It is the flow chart of the first embodiment of the flue gas emission prediction method of the present invention. In this embodiment, the flue gas emission prediction method includes the following steps:

[0081] Step S10: Obtain the flue gas sample data collected by the flue gas data extraction tool. The flue gas sample data includes the flue gas emission index data to be detected, analog data and switch data. The continuous parameter data of the gas, the switch value data is the discrete parameter data of the flue gas in the production process;

[0082] In the prior art, the dosage of environmentally friendly materials (including lime and ammonia, etc.) is usually controlled and adjusted by engineers or relevant staff after observing the real-time fluctuations of pollutants during flue gas emission. In this way, during the adjustment process, the accuracy of the prediction of flue gas emission indicators will be affected by the enginee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com