Coreless motor

A coreless cup and PCB board technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of large resistance and increased proportion of resistance, and achieve the reduction of motor resistance, reduction of motor resistance and temperature rise Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

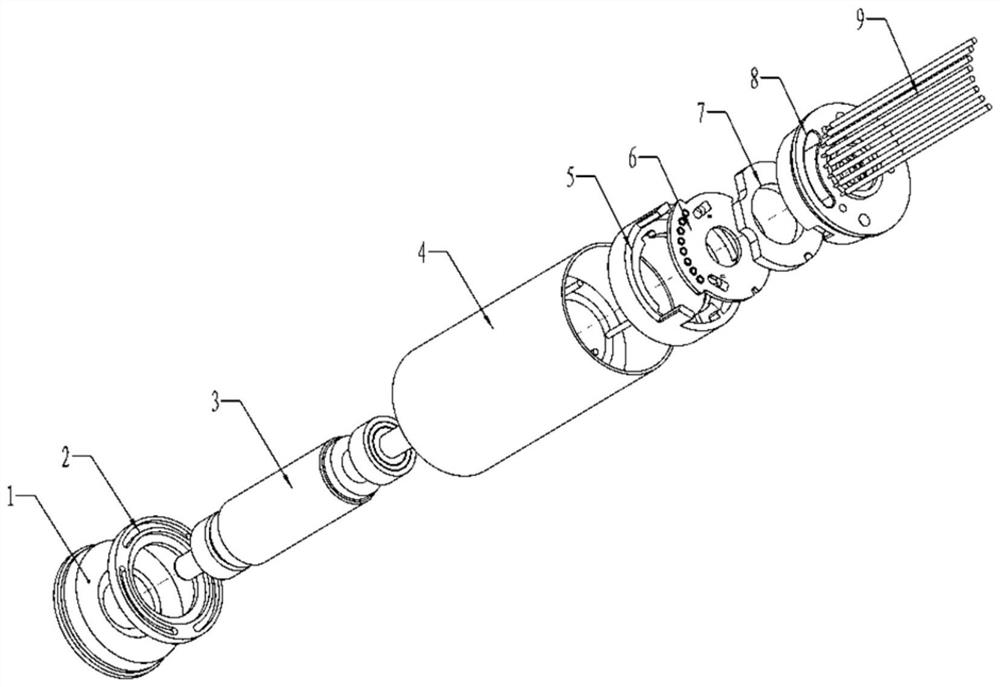

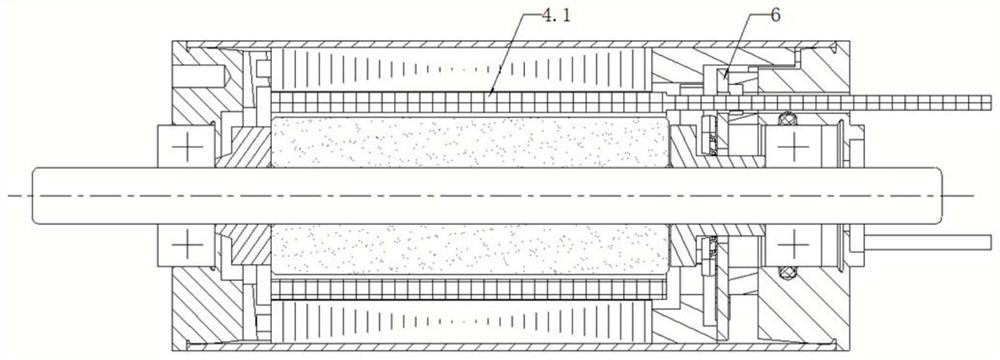

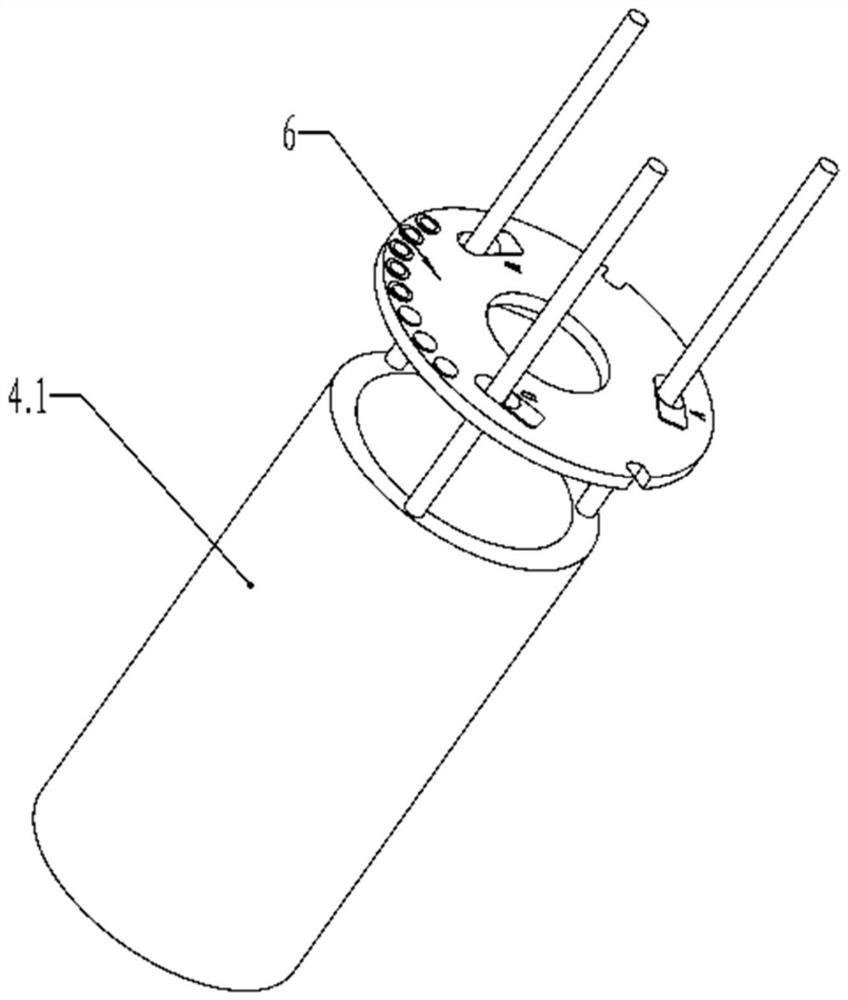

[0025] Such as figure 2 and image 3 As shown, a hollow cup motor includes a rotor 3, a stator 4 and a PCB board 6, the stator 4 is provided with a winding 4.1, and the taps of the winding 4.1 pass through the PCB board 6 and directly extend as terminals, so that Eliminate internal connection lines and reduce resistance.

[0026] In the present invention, the winding tap is connected to the customer connection terminal to save the internal circuit of the intermediate PCB board, so as to reduce the resistance. The winding 4.1 is wound with self-adhesive wire with a thick wire diameter, which can effectively reduce the resistance while ensuring the performance of the motor.

[0027] The PCB board 6 is provided with through holes for taps to pass through. The through hole is a waist hole, which is convenient for fine adjustment. The number of said through holes is set according to needs, preferably 3.

Embodiment 2

[0029] Such as Figure 4 and Figure 5 As shown, the taps of the winding 4.1 and the terminals (wire harness / copper sheet, etc.) are welded on the PCB board 6 together, so as to save the internal connection line and reduce the resistance. The PCB board 6 is provided with a Solder holes for tap and terminal soldering. The welding holes are waist-shaped holes, which are convenient for fine-tuning. The number of the welding holes is set according to needs, preferably 3. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com