Linear motor active disturbance rejection control design method based on Taylor tracking differentiator

A technology of tracking differentiator and active disturbance rejection control, which is applied in motor generator control, AC motor control, electronic commutation motor control, etc. It can solve the problems of the system being susceptible to interference and poor robustness, and improve the servo tracking accuracy , the effect of high tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

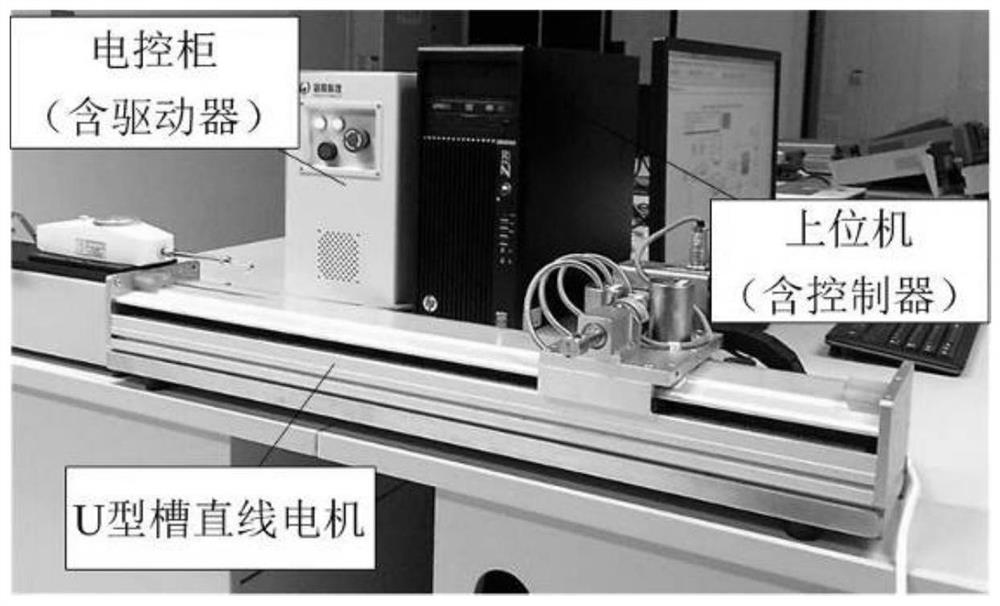

[0064] In order to verify the feasibility of the ADRC design method based on Taylor tracking differentiator provided by the present invention, in the attached figure 2 The verification is performed in the linear motor control system shown:

[0065] Based on the control design method proposed in this paper, the attached figure 2 The load of the linear motor system in is a weight with a total mass of 1.4kg, the mass of the linear motor mover is 1.79kg, the driver constant Ka=0.84A / V, and the thrust coefficient is Km=15N / A, and then use them to respectively Substitute into formula (1)-(6).

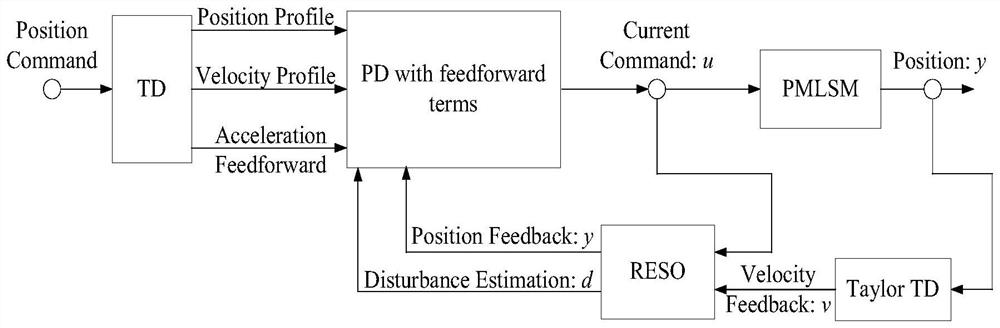

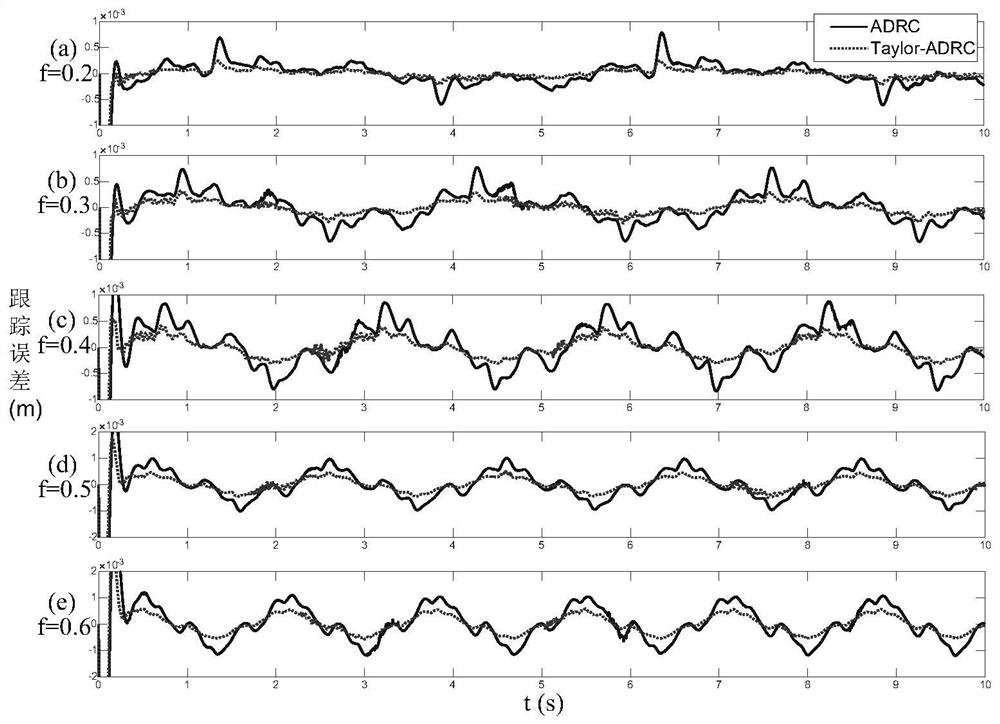

[0066] The ADRC design method based on Taylor tracking differentiator provided by the present invention is compared with the traditional ADRC design method, the controllers all use the PD controller with feedforward compensation, and the linearity of the traditional ADRC controller The extended state observer is designed as follows:

[0067]

[0068] Among them, if ω o When taking a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com