Method for calculating number of PROFIBUS-PA bus network segment equipment

A calculation method and bus technology, applied in the direction of bus network, digital transmission system, data exchange network, etc., to achieve the effect of high practical application value, reduced design rework and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

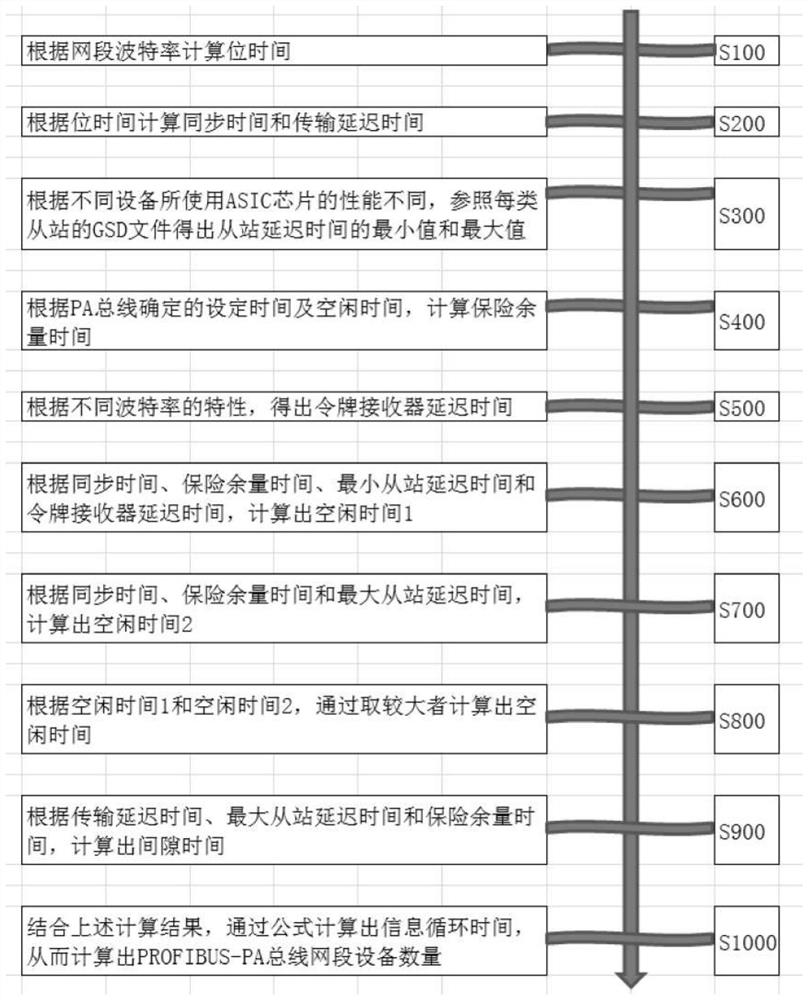

Method used

Image

Examples

Embodiment

[0105]The PROFIBUS-PA bus network segment in this embodiment includes one PROFIBUS-DPV0 master device node, and it is set that the master station is only connected to one network segment each time. The PA network segment uses a coupler for physical layer conversion. The feed voltage and feed current of the PA coupler are 24V / 1000mA respectively. The baud rate of the PA network segment is 31.25kbit / s, the number of PA slave stations is m, and each slave station has 5 bytes of input data and 5 bytes of output data.

[0106] The bit time is calculated based on the following formula (1):

[0107]

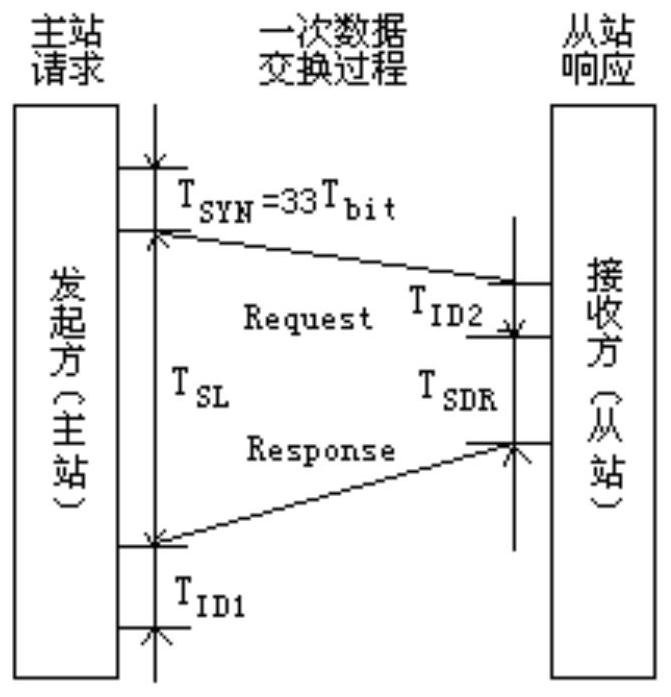

[0108] Synchronization time and transmission delay time are calculated based on the following formula (2):

[0109] T syn =33T bit

[0110] T td =33T bit (2)

[0111] where T syn refers to the synchronization time, T td Refers to the transmission delay time, both of which are 33T bit

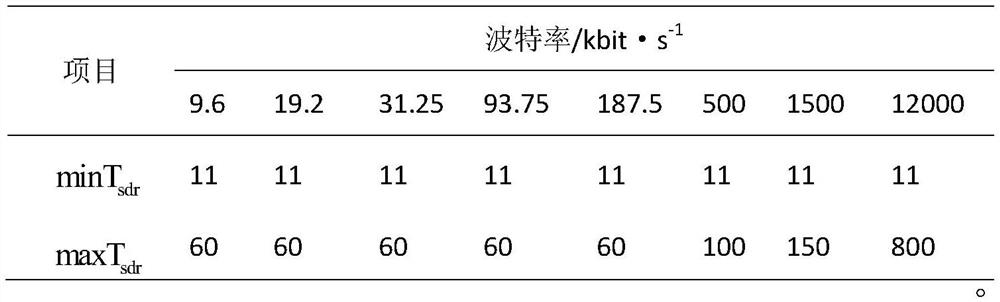

[0112] The minimum and maximum values for the slave delay time are determined based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com