Mobile ballast water treatment system for port

A treatment system and ballast water technology, applied in water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve ship port delays, large ballast water volume, and ballast water treatment system costs Expensive and other problems, to achieve complete sterilization effect and meet sterilization requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

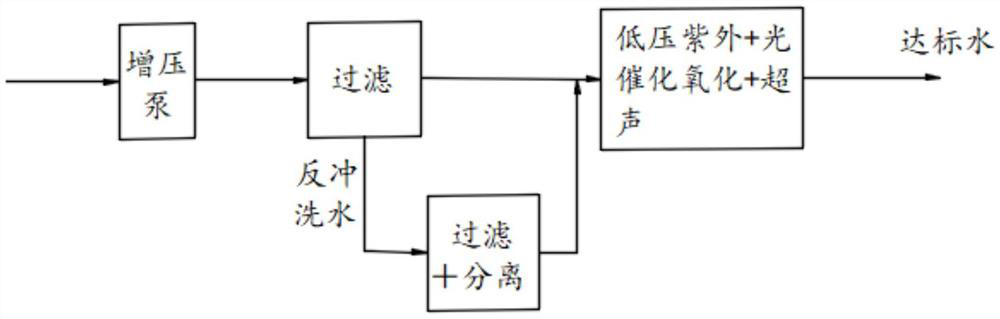

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

[0012] The mobile ballast water treatment system for ports is mainly suitable for ships calling at the port. It mainly solves the problem of ballast water treatment for ships calling at the port. Through the modularized ballast water treatment system, the system is placed in a standard container, which is convenient for port Mobile to meet the ballast water treatment needs of ships in port, simple and safe!

[0013] Arrange a booster pump at the inlet of the system to ensure the normal pressure of the system operation and avoid no pressure or low pressure of the water input by the ballast pump due to the large pressure loss of the long delivery pipeline. The water from the booster pump enters the high-precision automatic backwash filter, and the filtered water flows into the secondary sterilization unit. The secondary sterilization unit combines "low-pressure ultraviolet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com