Squeezing method of continuous deep dehydration equipment

A deep dehydration and equipment technology, which is applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve problems affecting dehydration links, intermittent operation of equipment, good fluidity, etc., and reduce labor costs , easy to adjust the pressure, and the effect of small fluctuations in the moisture content of the discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

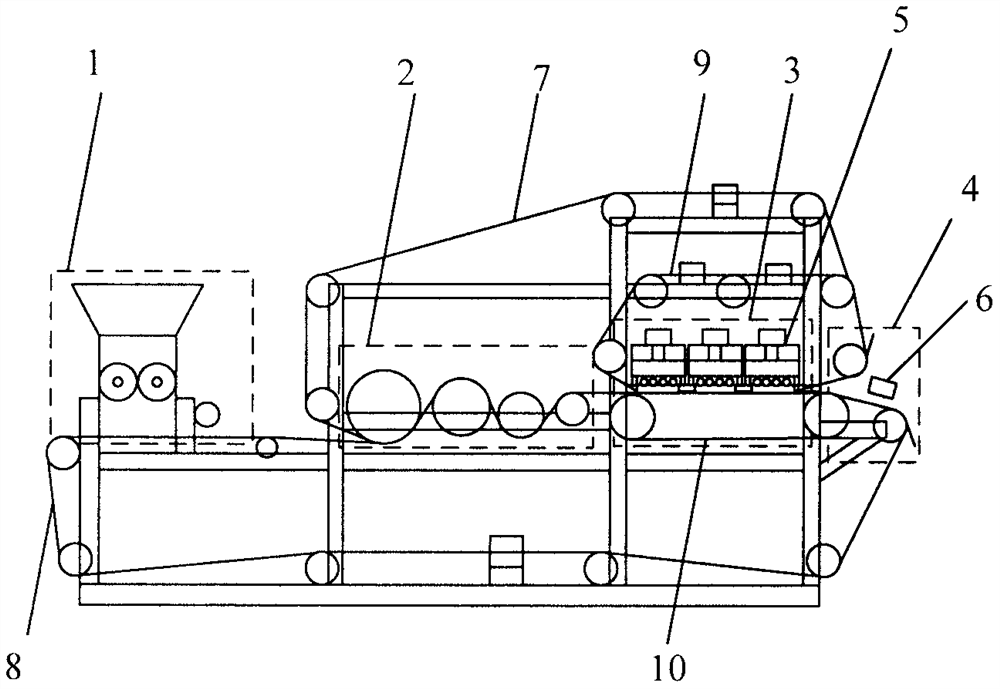

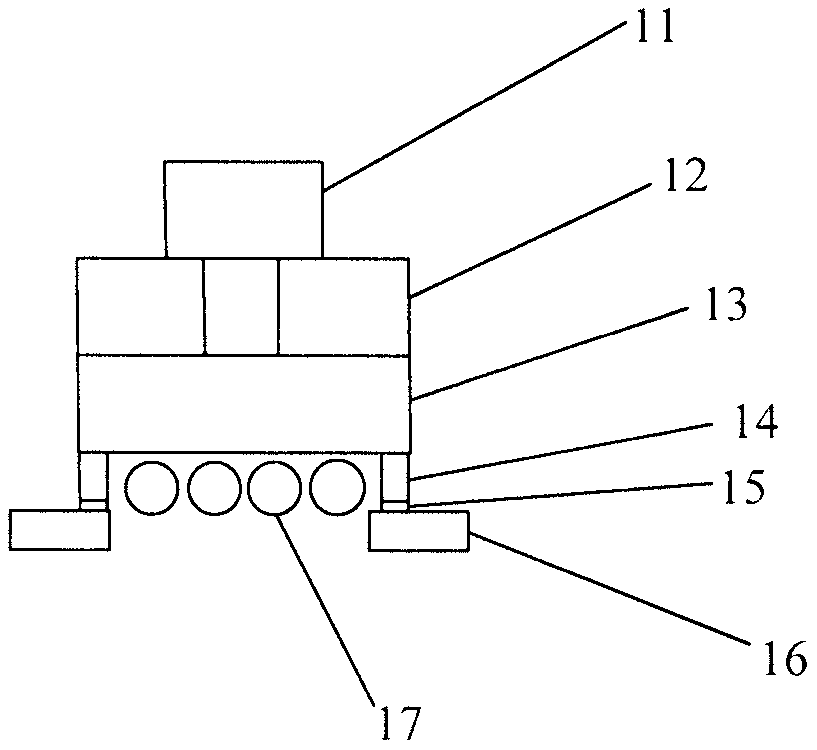

[0018] A pressing method for continuous deep dehydration equipment, characterized in that: the continuous deep dehydration equipment is mainly composed of a cloth distribution area (1), a pre-pressing area (2), a pressing area (3) and a discharge area (4) ; The outlet of the discharge area (4) is equipped with a moisture content on-line detector (6); the press area (3) is mainly composed of an upper lining belt (9), an upper filter screen (7), a lower filter screen (8), lower backing belt (10), pressurization assembly (5), the upper backing belt (9), upper filter screen (7), lower filter screen (8) and lower backing belt (10) of circulating operation are in The pressing area overlaps to form a pressing surface, and the pressurizing component acts vertically on the pressing surface; the pressurizing component consists of a pressurizing cylinder or oil cylinder (11), a fixed plate (12), a movable plate (13), a rolling body (17), an elastic body (14), the pressurizing assembly (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com