Folding shade shed

A pergola and cross-pipe technology, applied in tents/canopies, building types, buildings, etc., can solve problems such as rising costs, insufficient rigidity of the system, and inability to automatically extend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

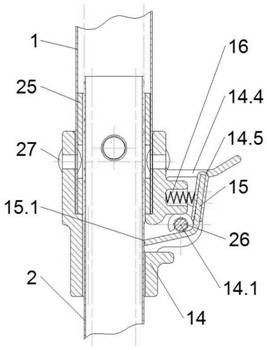

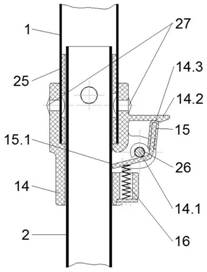

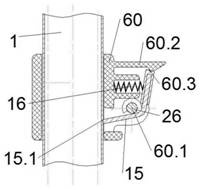

[0093] refer to Figure 1 to Figure 28 ,with Figure 43 , Figure 44 , Figure 47 , Figure 70 , including: vertical casing (1), telescopic leg pipe (2), side horizontal cross pipe (3, 51), middle horizontal cross pipe (4, 58), side oblique cross pipe (5, 52), middle oblique Cross pipe (6, 59), rigid hinge (7, 8, 9, 10, 11, 28, 29, 50, 65), hinge (23), one-way lock (14, 15, 16), vertical Pipe sliding sleeve (13, 55) or standpipe one-way sliding sleeve device (60, 15, 16), fixed support (12, 56), sliding support (53), one-way limit block (24), two-way limit block (57), horizontal crossing ropes (18), oblique side orthogonal ropes (31), oblique crossing ropes (30), jacking tubes (17), rope supports (54), also includes four-corner extension ceiling devices, including extension Pipe (102,113), sliding extension support (101), sliding pin (103), fixed extension support (110,112), outer edge rope (105,115), extension pipe end rope support (104,114), and Can include deflection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com