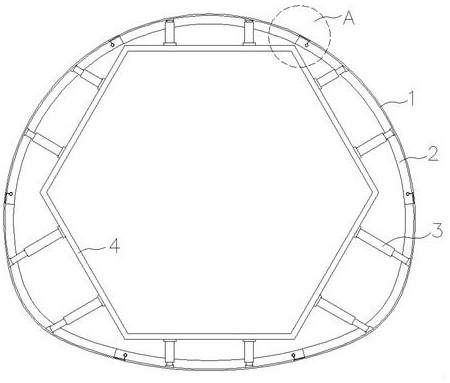

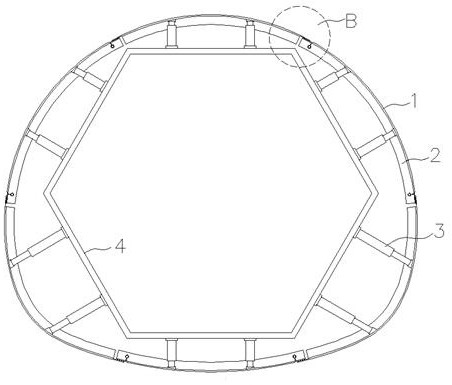

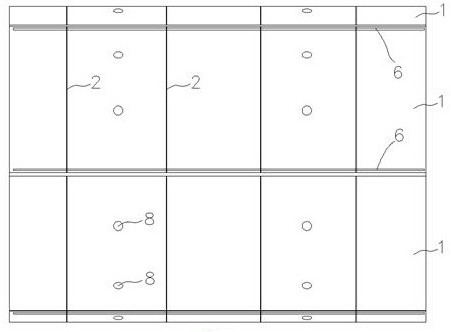

Variable-diameter shield body and diameter changing method

A shield body and variable technology, which is applied in the field of shield machines, can solve the problems of limited variable diameter shield body diameter range, difficult removal of muck, and high risk of machine jamming, so as to achieve flexible construction methods, improve tunneling efficiency and construction Safety factor, reducing the effect of entering the shield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0038] Embodiment 3: a kind of method for changing the diameter of the variable-diameter shield body as described in embodiment 2, the shield body is changed from a small diameter to a large diameter and the shield body is changed from a large diameter to a small diameter two processes; the shield body is changed from a small diameter to a large diameter step As follows: the telescopic member 3 protrudes outwards, driving the segmented shell 1 to protrude outwards to form the largest ring body; at this time, the outer flexible body 5 and the inner support body 9 of the sealing structure are sealed and overlapped, and the outer flexible body 5 and the inner support body 9 are sealed and overlapped. The supporting body 9 is in the state of the minimum overlapping surface. In this state, the annular shield composed of the block shells still maintains a complete ring state and good sealing performance in the circumferential direction, reducing the entry of rock and soil debris into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com