Train brake shoe abrasion detection device and method

A detection device and technology for train brakes, applied in the field of train brake shoes, can solve the problems of uneven wear degree of friction blocks, surface wear of brake shoe friction blocks, hidden dangers of train operation safety, etc., so as to achieve traceability management of brake shoe replacement and reduce Brake shoe waste, the effect of automatic management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments.

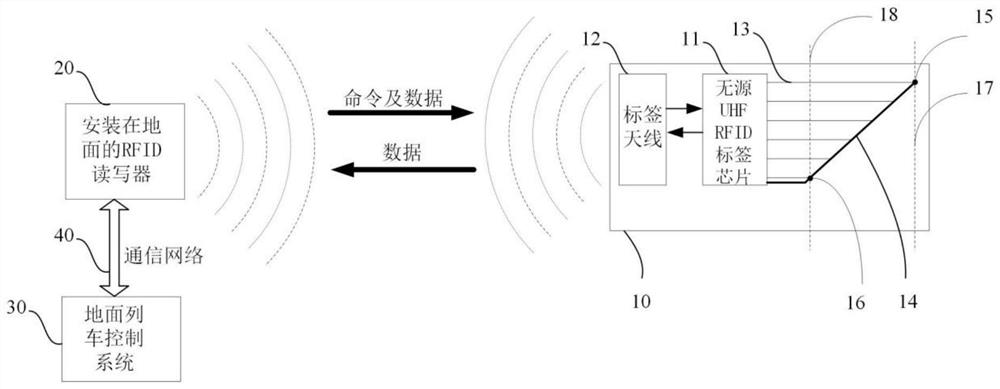

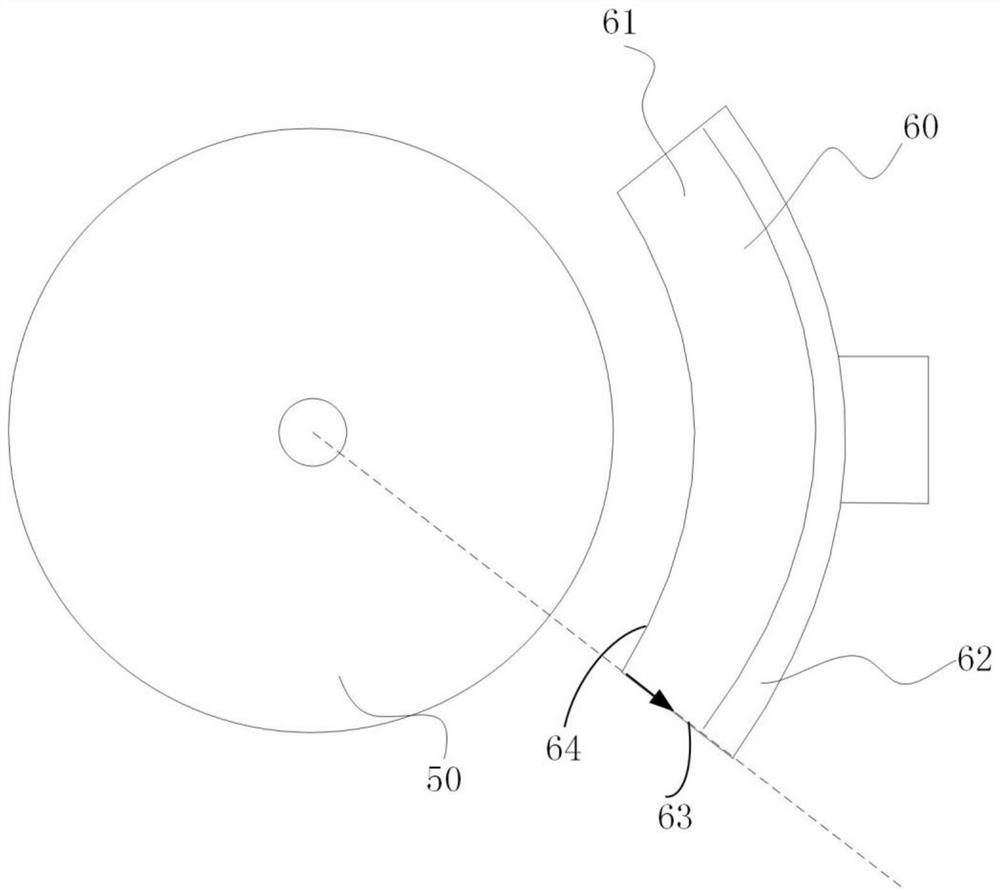

[0026] Such as figure 1 As shown, a train brake shoe wear detection device provided by the present invention includes a passive UHF RFID brake shoe wear detection electronic tag 10 installed on the train brake shoe, an RFID reader 20 installed on the ground and a compatible brake shoe wear A ground train monitoring system 30 with a detection function; the passive UHF RFID brake shoe wear detection electronic tag 10 includes a plurality of position detection wires 13 for brake shoe wear detection, a common wire 14, and a detection wire interface and a common wire interface. Passive UHF RFID tag chip 11 and tag antenna 12, each position detection wire 13 and common wire 14 are respectively connected to the detection line interface and common wire interface of passive UHF RFID tag chip 11, and tag antenna 12 is connected to passive UHF RFID ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com