Wire peeling and recycling device

A technology for recycling devices and wires, which can be used in cable installation devices, electronic waste recycling, cable installation, etc., and can solve problems such as not being environmentally friendly and harming the body of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

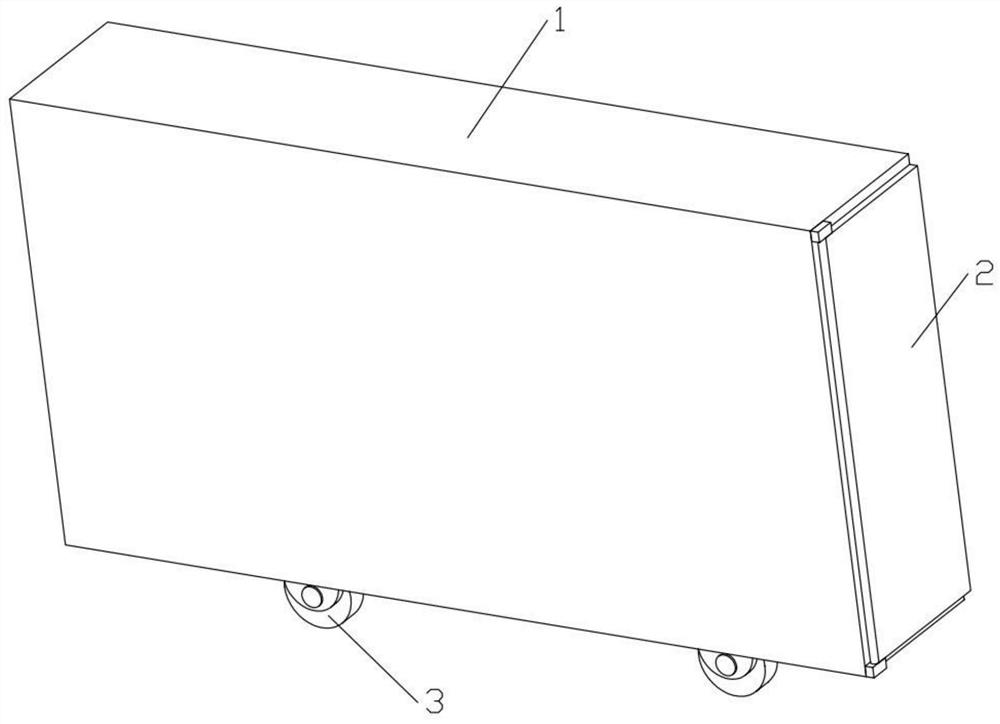

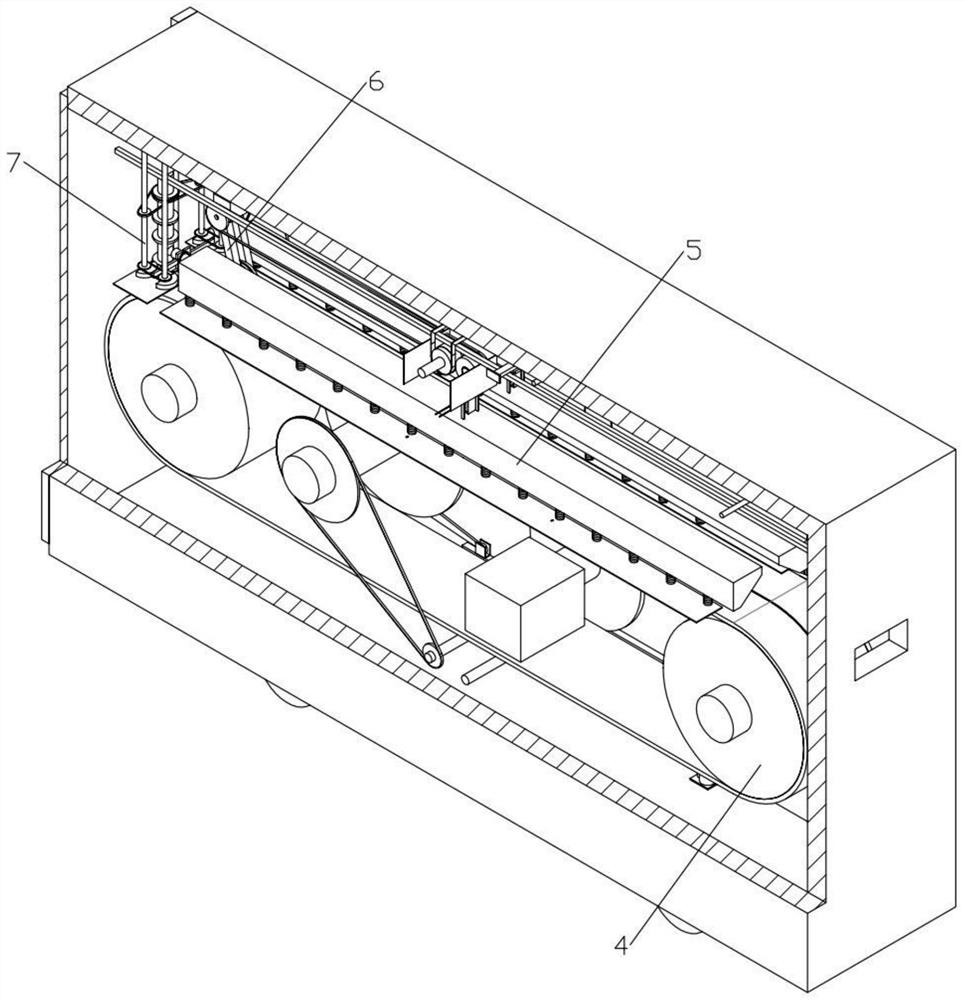

[0029] Combine below Figure 1-10 In order to solve the above technical problems, the present invention relates to the technical field of electric wire recycling, more specifically, a wire peeling and recycling device, including a housing 1, a retrieving door 2, a self-locking universal wheel 3, a transmission device 4, and a clamping device 5. Cutting device 6 and winding device 7; one end of the housing 1 is processed with a wire inlet hole, the other end of the housing 1 is hinged with the retrieving door 2, and the bottom end of the housing 1 is processed with a shedding hole, the bottom end of the housing 1 is provided with several groups of self-locking universal wheels 3, the housing 1 is provided with a transmission device 4, the transmission device 4 is provided with a clamping device 5, and the housing 1 is also provided with a cutting device 6 and a winding device 7;

[0030] Push the device to the desired position through the self-locking universal wheel 3, and pu...

specific Embodiment approach 2

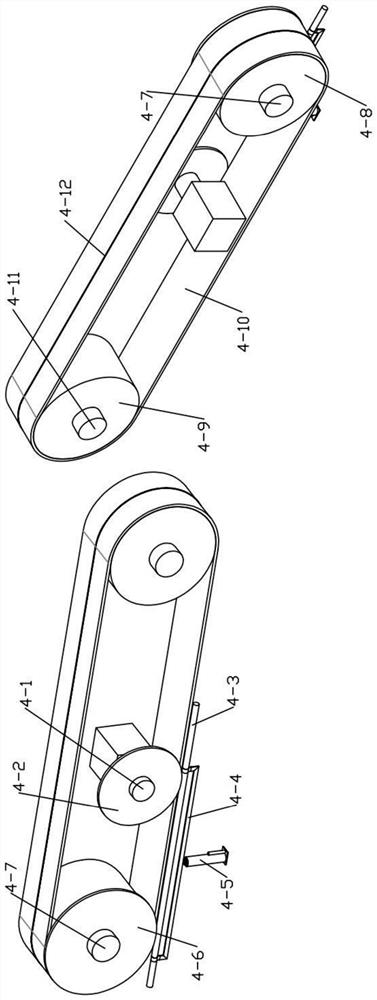

[0032] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the transmission device 4 includes a transmission motor 4-1, a first transmission turbine 4-2, a transmission worm 4-3, and a connecting frame 4-4, which are reflected in the specification Structure, transmission electric telescopic rod 4-5, second transmission turbine 4-6, first transmission shaft 4-7, first transmission pulley 4-8, second transmission pulley 4-9, transmission connection belt 4-10, The second transmission shaft 4-11 and the first cutter 4-12; the main shaft of the transmission motor 4-1 is provided with the first transmission turbine 4-2, and the first transmission turbine 4-2 and the transmission worm 4-3 The transmission worm 4-3 is provided with a connection frame 4-4, and the lower end of the connection frame 4-4 is provided with a transmission electric telescopic rod 4-5, and the transmission worm 4-3 is also connected with the second tr...

specific Embodiment approach 3

[0036] Combine below Figure 1-10 This embodiment will be described. This embodiment will further describe the second embodiment. The clamping device 5 includes a first clamping pulley 5-1, a second clamping pulley 5-2, a first clamping shaft 5- 3. Clamping clutch turbine 5-4, first clamping transmission belt 5-5, clamping electric telescopic rod 5-6, movable connection block 5-7, clamping clutch worm 5-8, third clamping pulley 5 -9, the fourth clamping pulley 5-10, the fifth clamping pulley 5-11, the sixth clamping pulley 5-12, the second clamping drive pulley 5-13, the second clamping shaft 5- 14. The third clamping shaft 5-15, the connecting plate 5-16, the first clamping gear 5-17, the second clamping gear 5-18, the fourth clamping shaft 5-19, the clamping frame 5-20 , the first clamping rod 5-21, the clamping block 5-22, the clamping transmission frame 5-23, the clamping block 5-24, the pressing plate 5-25 and the clamping spring 5-26; the first clamping The pulley 5-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com