A kind of fan blade structure for cooking equipment and oven with the structure

A technology of cooking equipment and fan blades, which is applied in the field of cooking equipment, can solve the problems of inability to adjust and constant airflow velocity, and achieve the effect of improving the overall baking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

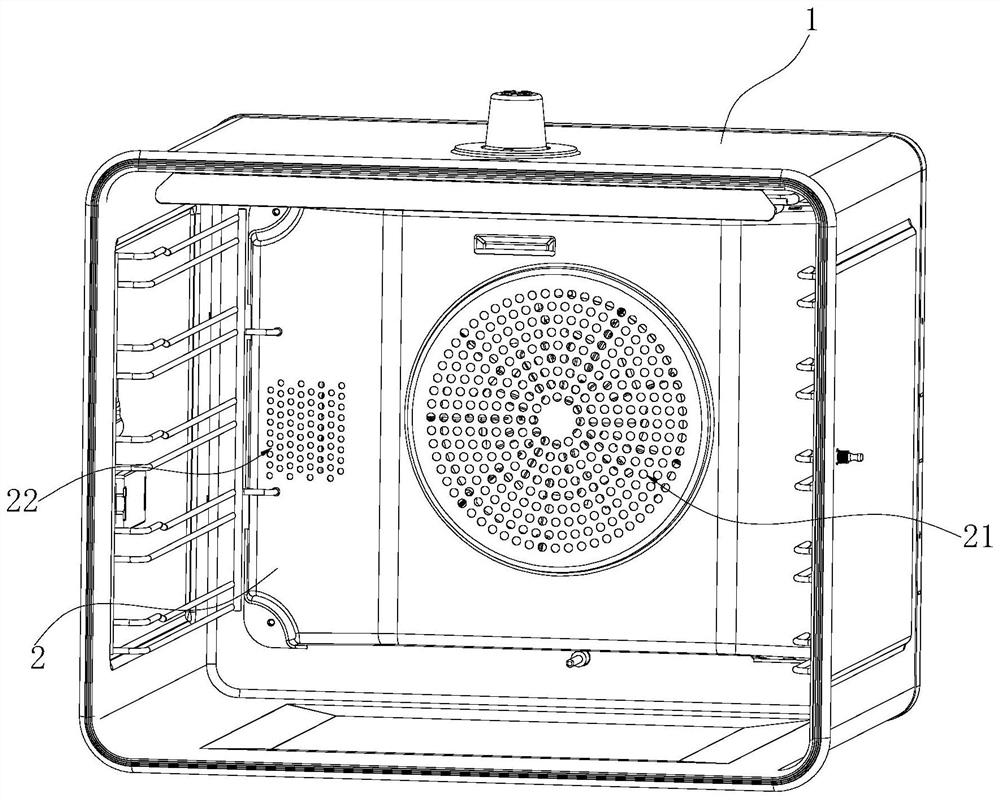

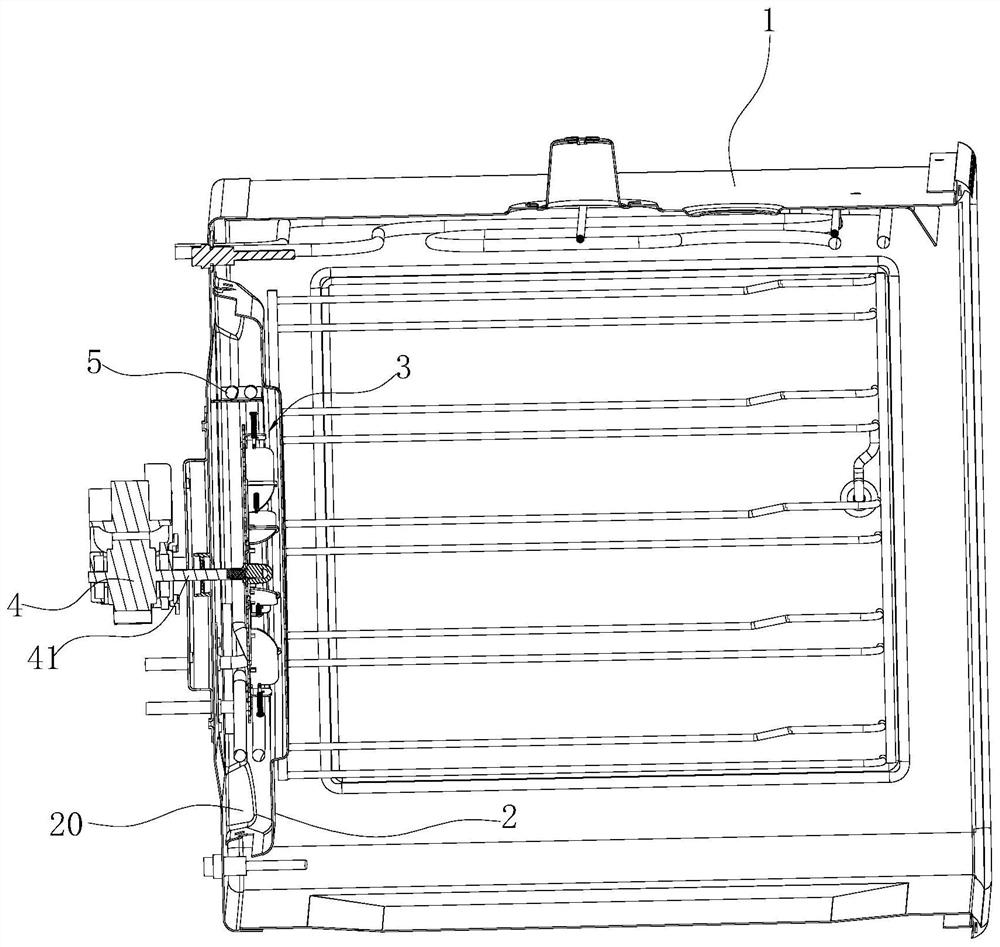

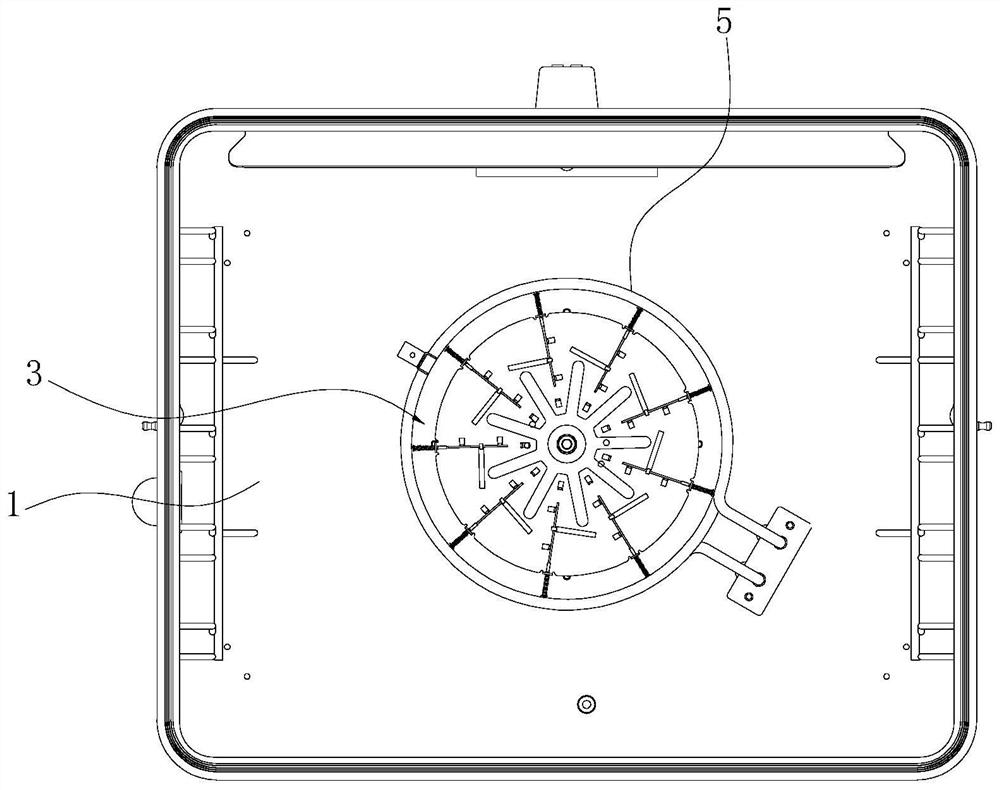

[0026] like Figure 1~6 As shown, an oven includes an inner container 1 and a fan blade structure 3. The rear side of the inner container 1 is vertically provided with a hot air baffle 2 with an air inlet 21 and an air outlet 22. The hot air baffle 2 and the inner container The backboard of 1 encloses the hot air chamber 20, and the rear surface of the backboard of the liner 1 is equipped with a hot air motor 4, and the motor shaft 41 of the hot air motor 4 penetrates in the above-mentioned hot air chamber 20 along the front and rear direction, and the above-mentioned fan blades The structure 3 is located in the hot air chamber 20 and installed on the motor shaft 41 of the hot air blower motor 4 , and the outer periphery of the fan blade structure 3 is provided with an annular heating pipe 5 .

[0027] The fan blade structure 3 includes a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com