Efficient multistage sedimentation rake-free concentration device

一种浓缩装置、高效的技术,应用在沉降槽的进料/出料装置、沉降槽、脱水/干燥/浓缩污泥处理等方向,能够解决煤炭洗选质量影响、细泥不能有效脱出、沉降效果差等问题,达到改善洗选工艺恶化、加速粘附、减少浪费的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

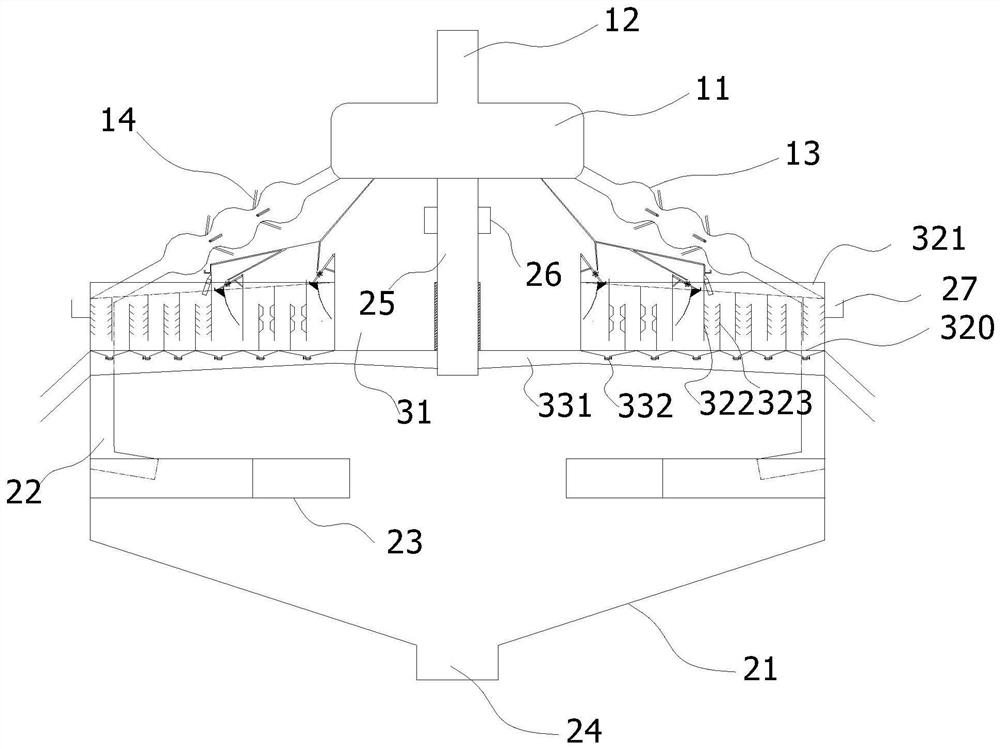

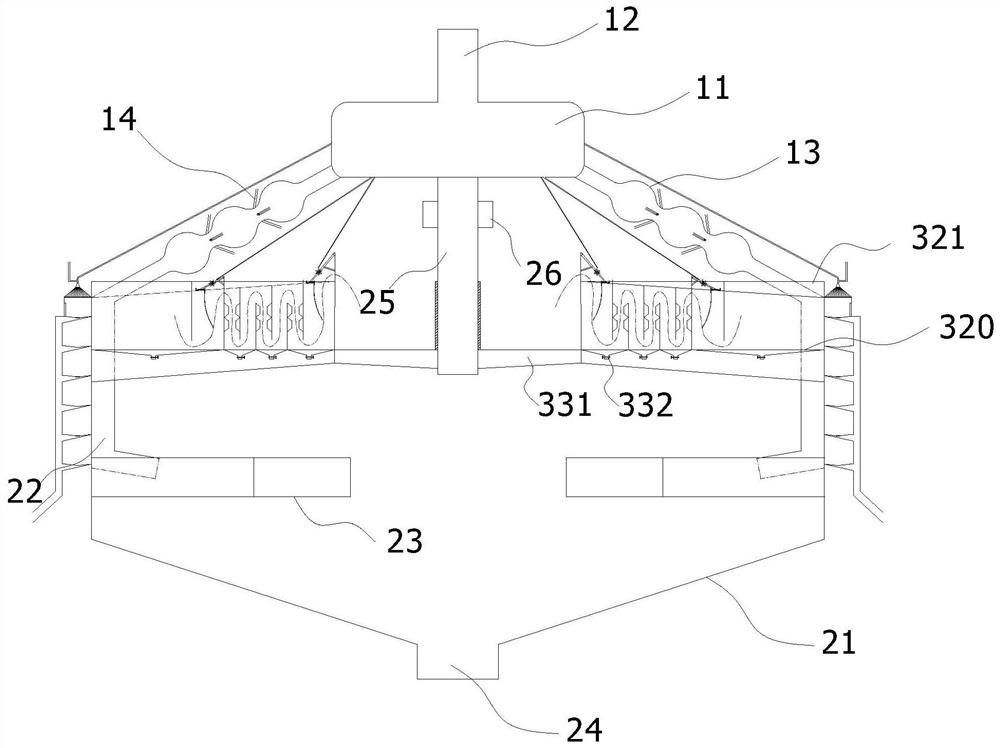

[0051]A high-efficiency multi-stage sedimentation rake-free thickening device includes a feed component, a diversion component, and a clean coal collection component. The guide assembly includes a central groove body 21 with a cylindrical part at the upper end and a funnel part at the lower end. The central groove body 21 has a cavity structure. The feed assembly is arranged above the cavity of the central groove body 21. The central groove The lower end of the body 21 is provided with a first discharge port 24. The coarse slime gradually sinks to the top of the first discharge port 24 of the central tank body 21 and deposits to a certain amount of deposition, and is discharged through the first discharge port 24 to collect the materials discharged from the first discharge port 24 , Used for blending of Chinese coal or as building materials to increase economic income.

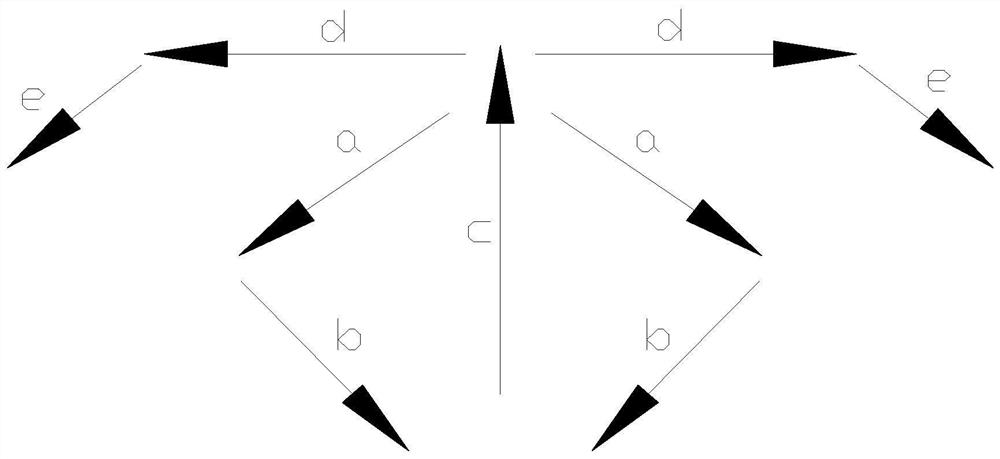

[0052]Such asfigure 1 As shown, the materials and medicaments enter the diversion component from the feed component,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com