Flushing device of reverse osmosis membrane for sea water desalination

A technology of flushing device and reverse osmosis membrane, which is used in reverse osmosis, seawater treatment, semi-permeable membrane separation, etc., can solve the problems of inconvenient fixation of reverse osmosis membrane, uneven spraying of flushing liquid, etc., so as to reduce operation difficulty and flushing efficiency. High, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

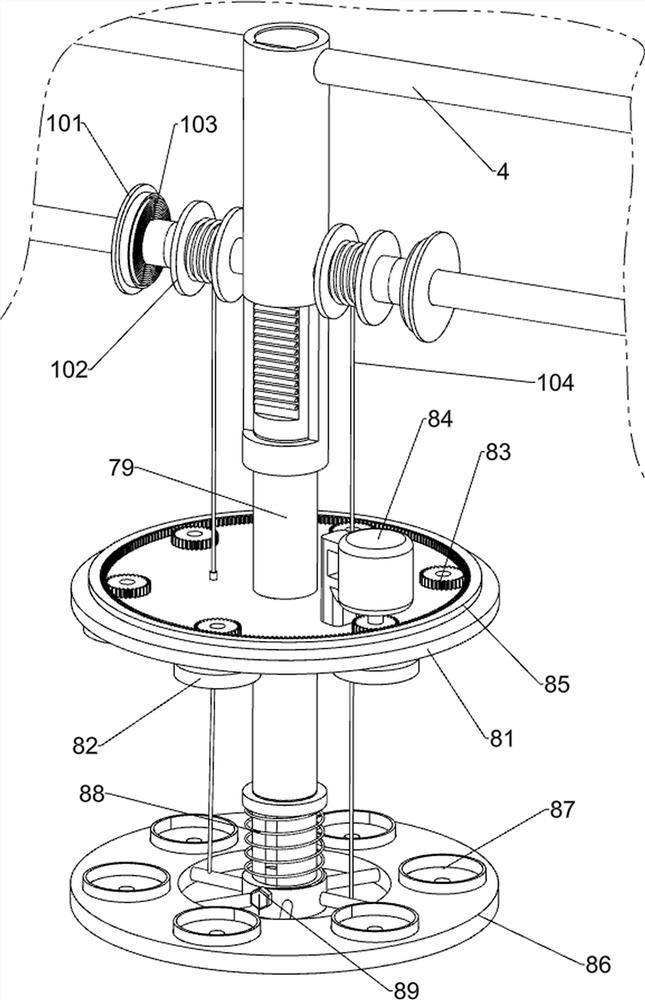

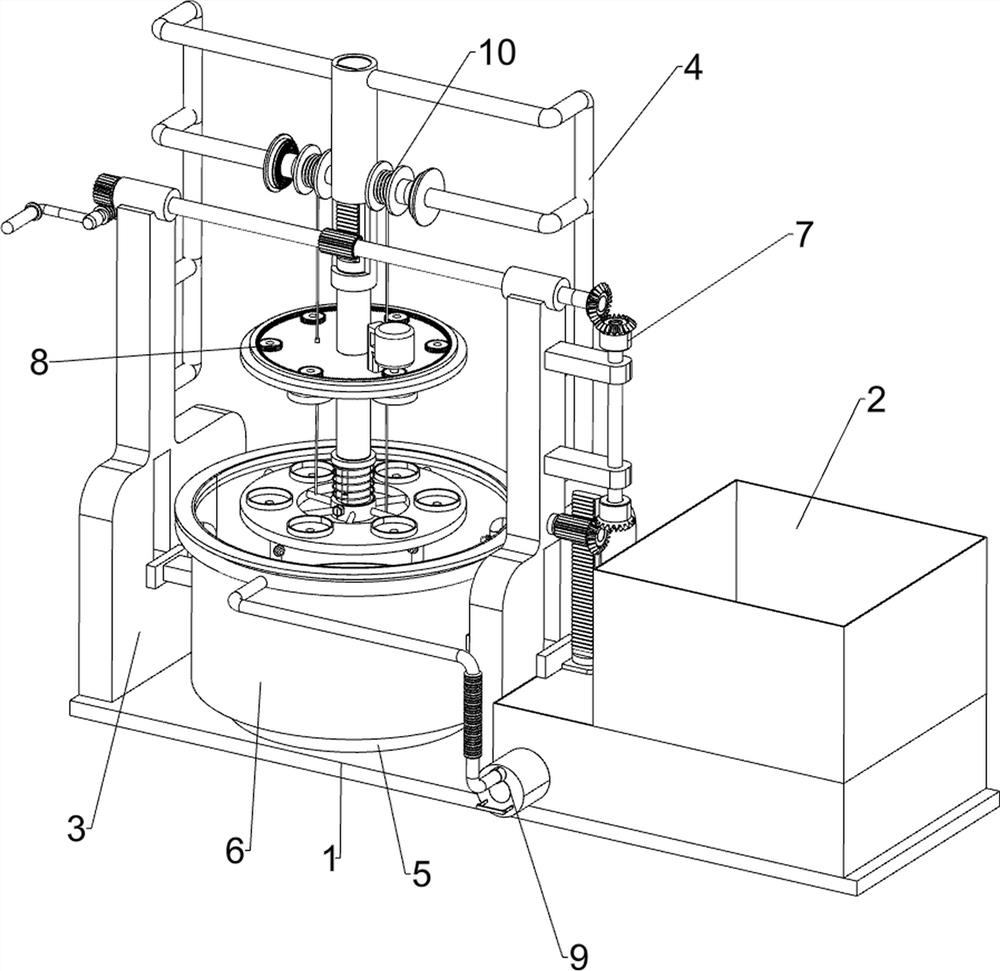

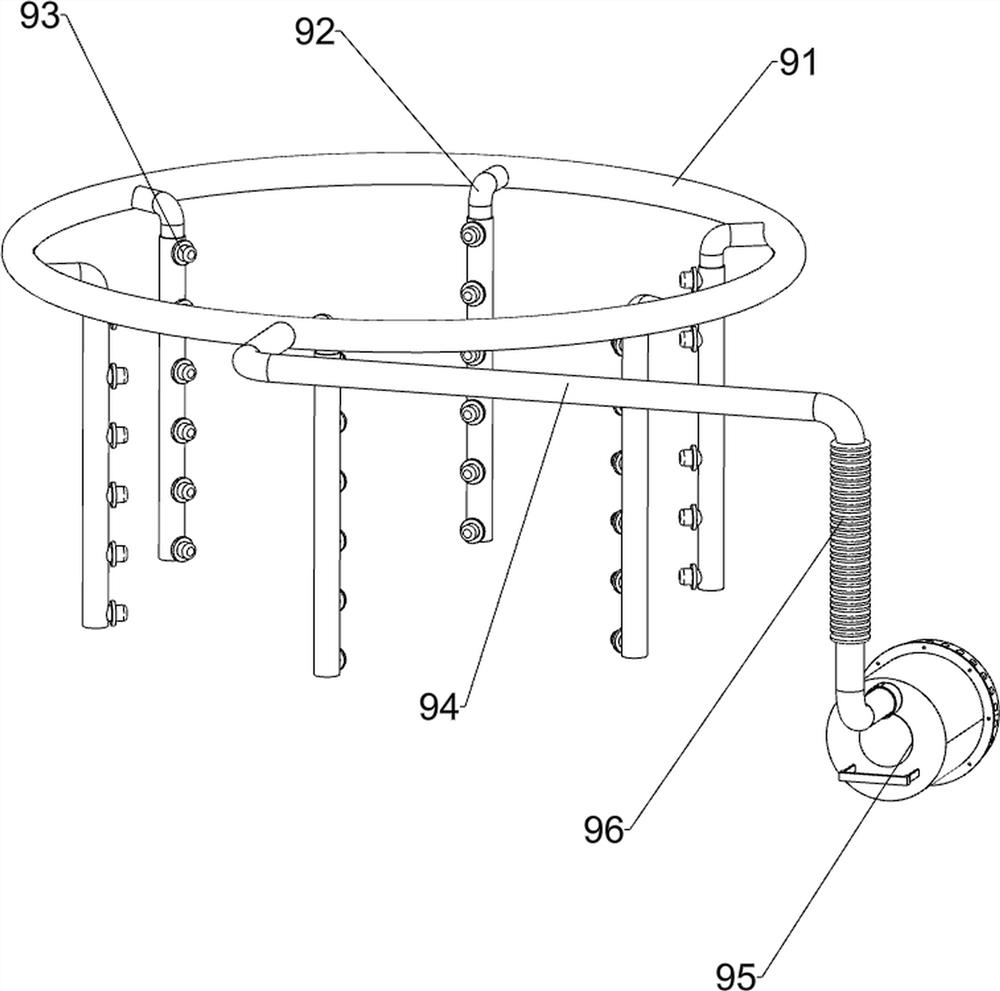

[0022]A flushing device of reverse osmosis membrane for seawater desalination, such asFigure 1-4As shown, it includes a base 1, a liquid storage tank 2, a support plate 3, a guide frame 4, a collection tank 5, a washing cylinder 6, a moving mechanism 7, a rotating mechanism 8 and a washing mechanism 9. A liquid storage is installed on the top right side of the base 1. Box 2, the top left side of the base 1 is connected with two support plates 3, the upper part of the two support plates 3 is connected with a guide frame 4, the top left of the base 1 is connected with a collection tank 5, the collection tank 5 is located on both sides of the support plates 3, the outer side of the collection tank 5 is slidably connected with a washing cylinder 6, a moving mechanism 7 is connected between the washing cylinder 6 and the support plate 3, a rotating mechanism 8 is installed on the moving mechanism 7, the storage tank 2 and the washing cylinder 6 A flushing mechanism 9 is connected between...

Embodiment 2

[0028]On the basis of Example 1, such asimage 3 As shown, the automatic clamping assembly 10 is also included. The automatic clamping assembly 10 includes a spring seat 101, a reel 102, a scroll spring 103, and a draw rope 104. The left and right sides of the guide frame 4 are connected with the spring seat 101. With the reel 102, the reel 102 is rotatably connected with the guide frame 4, a spiral spring 103 is connected between the spring seat 101 and the reel 102, and a drawstring 104 is wound on the reel 102, The tail end of the rope 104 penetrates the fixed disk 81 and is connected to the sliding disk 86.

[0029]Loosen the fastening bolt 89 first. When the sliding plate 86 moves down, the reel 102 is driven to rotate by the pull cord 104 to release the pull cord 104, and the scroll spring 103 is compressed. When the pull cord 104 on the reel 102 is completely After releasing, when the guide column 79 and the fixed disk 81 continue to move downward, the sliding disk 86 cannot move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com