Adjustable stamping equipment for hardware product machining

A stamping equipment and adjustable technology, which is applied in the direction of mechanical equipment, vibration suppression adjustment, spring/shock absorber, etc., can solve the problems of insufficient stability and disadvantages of stamping, and achieve the effect of avoiding shaking and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

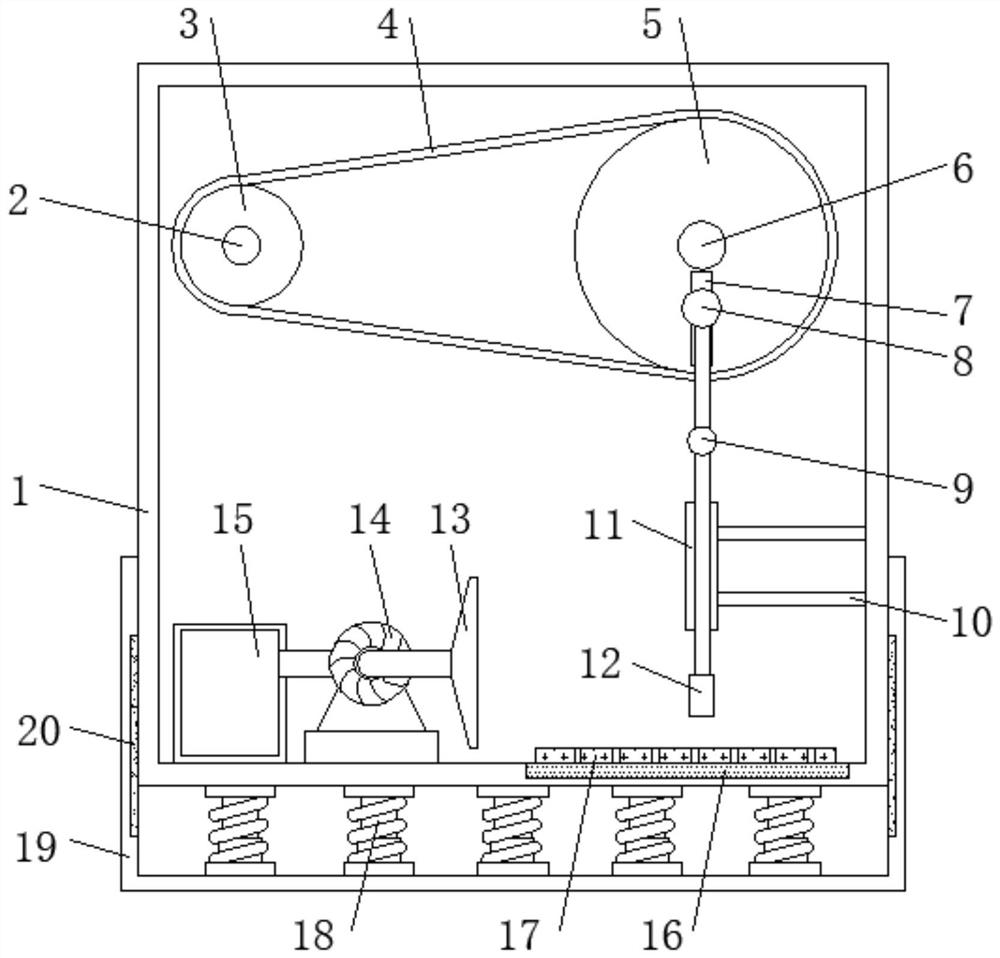

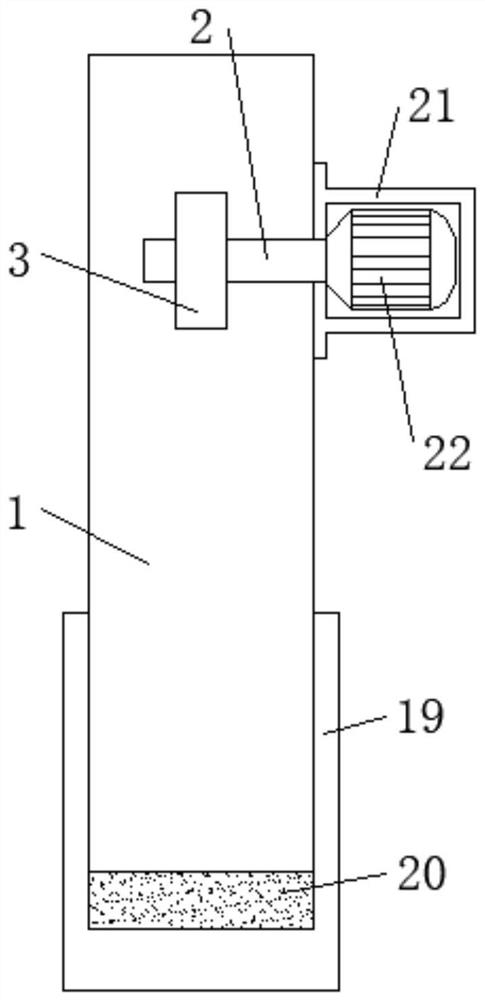

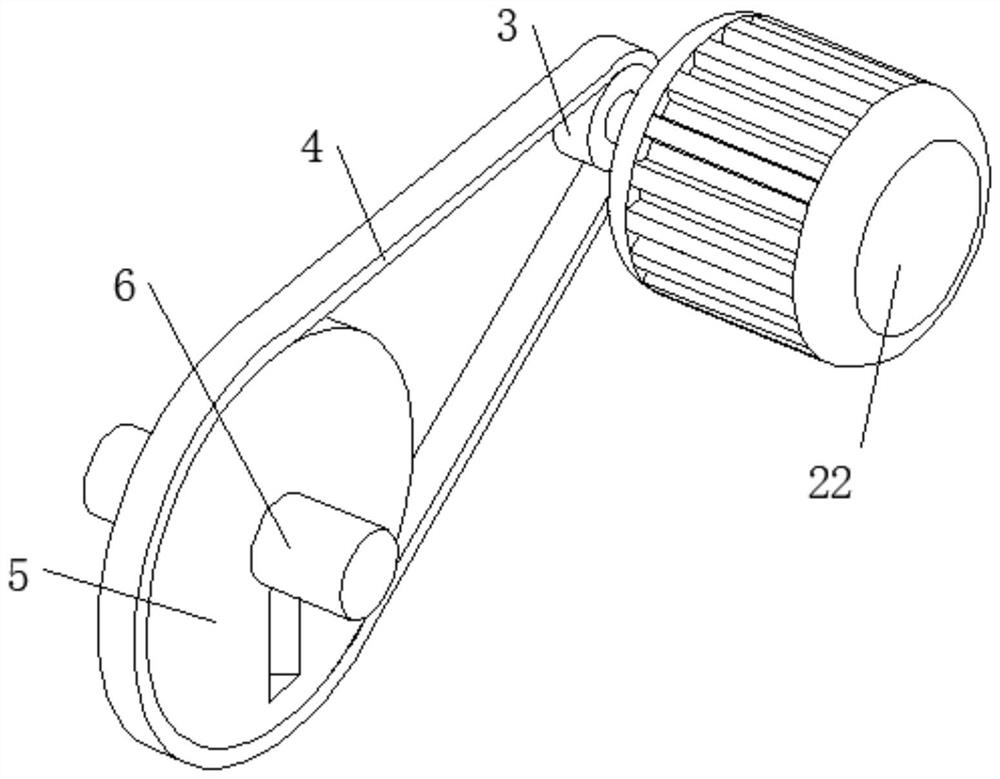

[0025] refer to Figure 1-3 , a kind of stamping equipment that can adjust the processing of hardware products, including a frame body 1, a rectangular groove is opened on one side of the bottom inner wall of the frame body 1, an air suction plate 16 is fixedly connected to the bottom inner wall of the rectangular groove, and the surface of the air suction plate 16 It is flush with the bottom inner wall of the frame body 1, and the support plate 17 is adsorbed on the top outer wall of the suction plate 16, and the bottom inner wall of the frame body 1 is provided with a dust suction mechanism, and the outer wall of one side of the frame body 1 is fixedly connected with a motor box 21. A motor 22 is fixedly connected to the inner wall of the motor box 21, and one end of the output shaft of the motor 22 is keyed to a transmission shaft 2, and a drive wheel 3 is sleeved on the outer circumference of the transmission shaft 2, and a drive wheel 3 is set on one side of the inner wall...

Embodiment 2

[0029] refer to Figure 4 , a stamping equipment that can be adjusted for processing hardware products. Compared with Embodiment 1, this embodiment has a rectangular frame 23 fixedly connected to one side of the outer wall of the frame body 1, and a battery 24 is fixedly connected to the inner wall of the rectangular frame 23.

[0030] When in use, a storage battery 24 is provided on one side of the frame body 1, and the storage battery 24 is used as a power supply source of the device, which facilitates the starting of the device, thereby making the stamping of the device more convenient and convenient for real-time use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com