Process for repairing nozzle of secondary fuel nozzle assembly of gas turbine

A fuel nozzle and nozzle technology, applied in the field of repair technology, can solve the problems of high cost, high maintenance cost, nozzle erosion of secondary fuel nozzle components, etc., and achieve the effects of reducing maintenance cost, improving accuracy and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

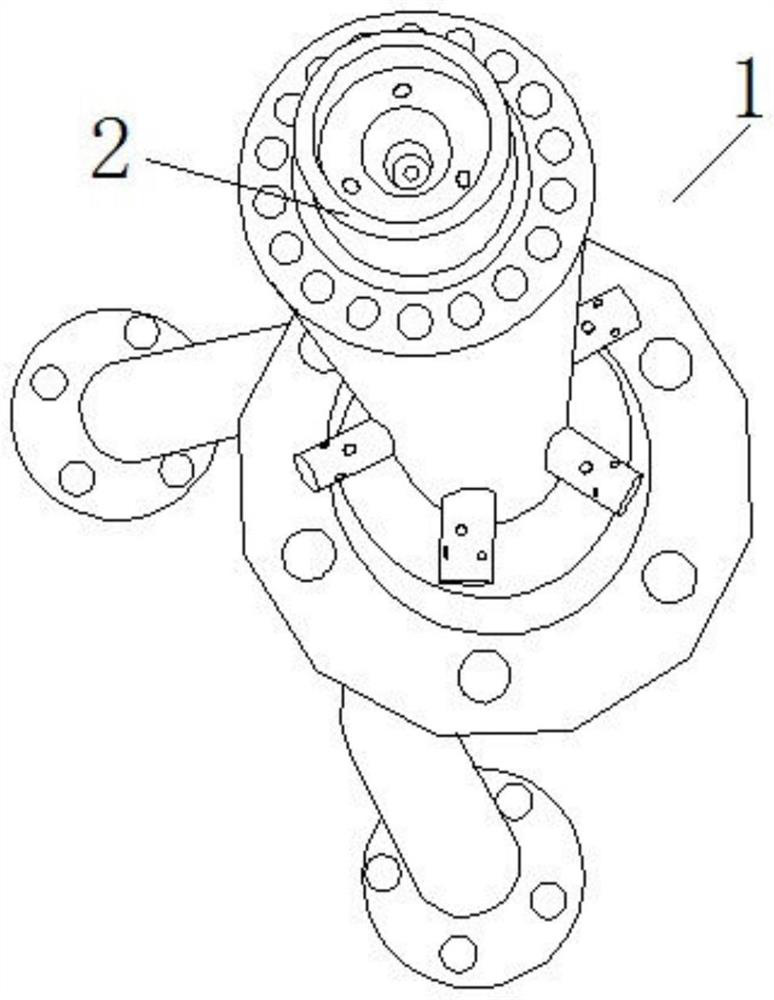

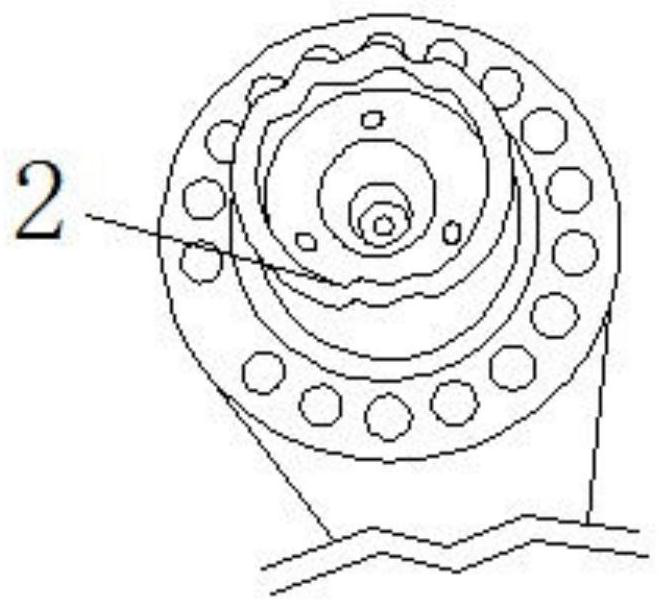

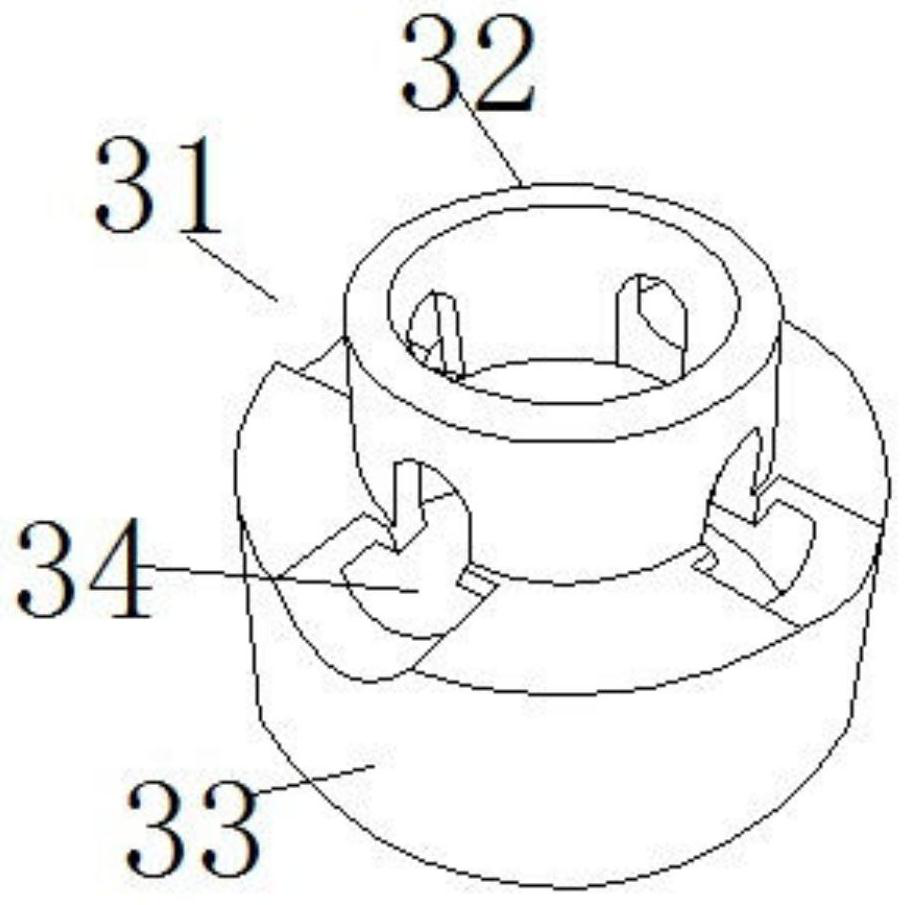

[0033] Such as Figure 1-6 As shown, a repair process for the nozzle of the secondary fuel nozzle part of the gas turbine, the repair process includes the following steps:

[0034] 1) Disassembly

[0035] Remove the inner core in the gas turbine secondary fuel nozzle part 1;

[0036] 2) Calculate:

[0037] First measure the size of the new secondary fuel nozzle part 1 and nozzle 2 of the same model, and reserve; check the position of the damaged nozzle 2 of the secondary fuel nozzle part 1, draw the cutting line, and then calculate the required shape and size repair parts according to the cutting line 5;

[0038] 3) Process repair part 5:

[0039] Processing the size repair part 5 recorded in step 2 by the machine tool, the size of the processed repair part 5 is greater than or equal to the calculated size of the repair part 5;

[0040] 4) Cutting:

[0041] Use a metal cutting machine to cut the nozzle 2 according to the cutting line mentioned in step 2), completely remo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap