Hydraulically-driven self-cleaning laminated filtering device of micro-irrigation system

A laminated filtration and hydraulic drive technology, which is applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc. Irrigation system, aggravating the investment of micro-irrigation system, etc., to achieve the effect of low maintenance cost, compact space occupation, and small installation footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

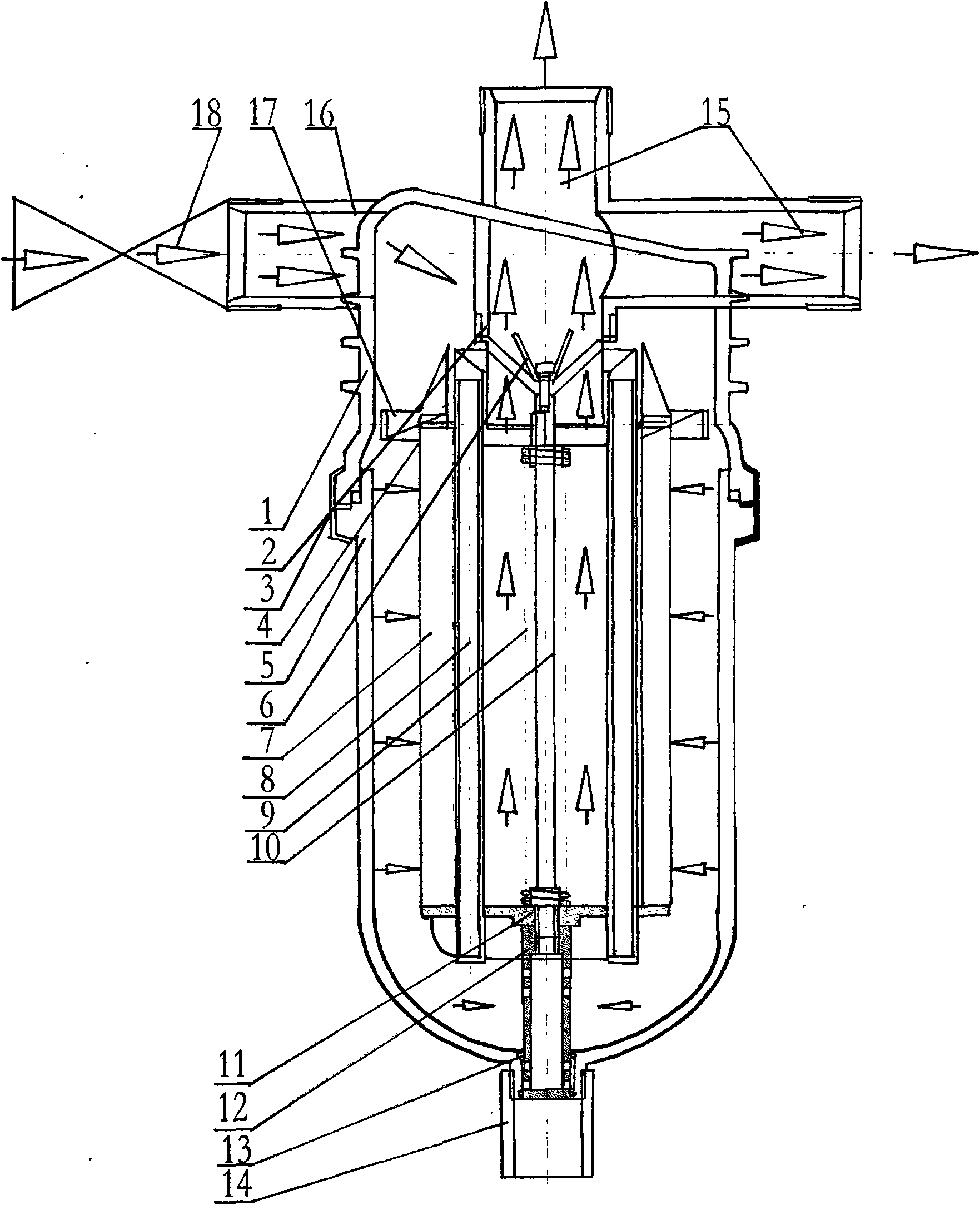

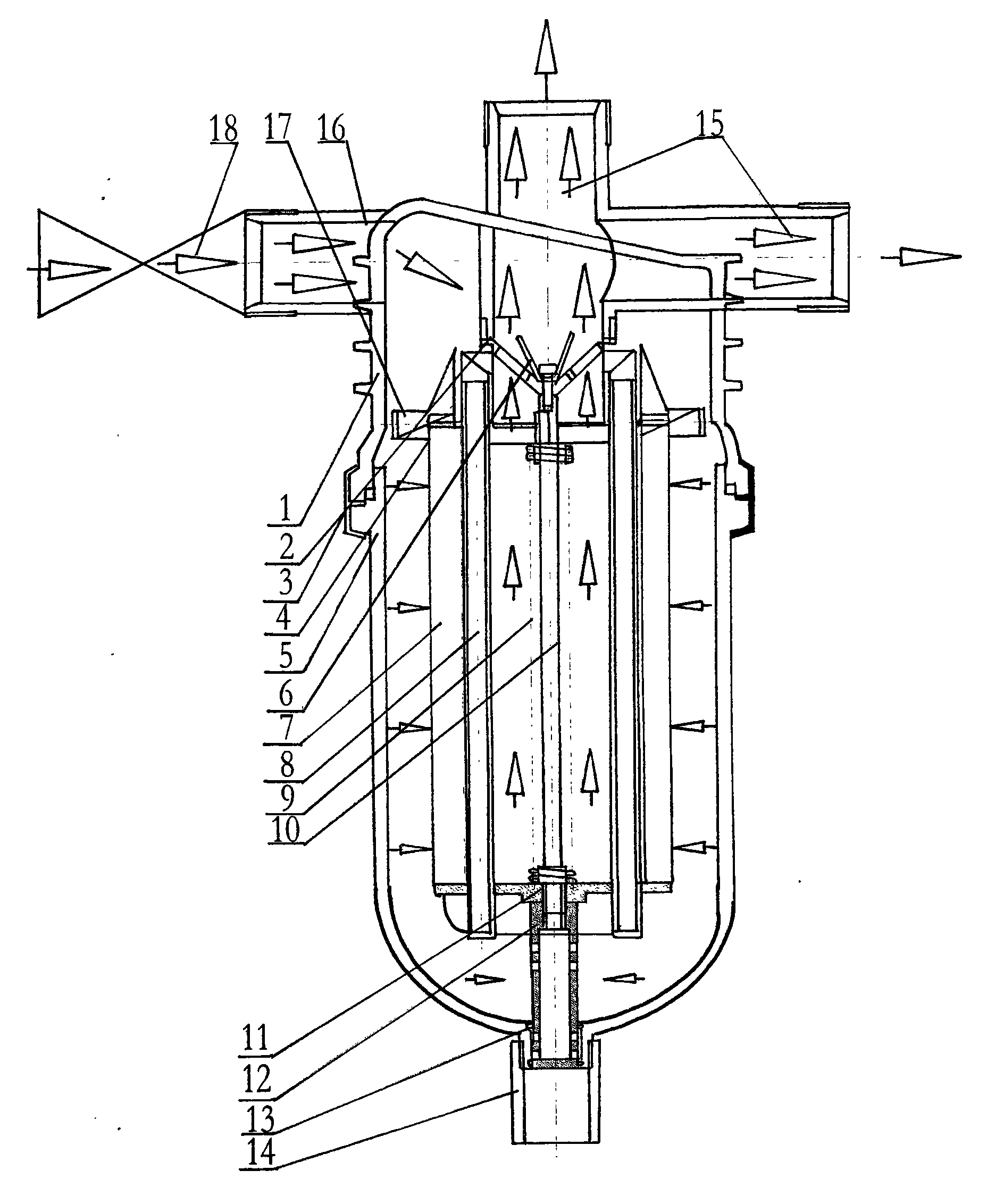

[0009] like figure 1 As shown, the upper shell 1 and the lower shell 5 of the hydraulically driven self-cleaning laminated filter device of the micro-irrigation system are sealed and connected to form a filter cavity through a quick connection clamp 3, and the upper part of the upper shell 1 is provided with a filter cavity. The water inlet 16 and the water outlet 15 communicate with each other, a hydraulic valve 18 is connected to the water inlet 16, a filter lamination group 7 is arranged in the filter cavity, and the filter lamination group 7 is formed with a filter cavity. The filter core cavity is concentric, the filter core cavity is communicated with the water outlet 15, the lower part of the filter lamination group 7 is installed with a lamination connection gland 11, and the inner sleeve of the filter lamination group 7 is connected with a backwashing injector 8, filtering The upper part of the lamination group 7 is provided with a connection seat 3, the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com