Automatic polishing equipment for tungsten steel strips and method for processing tungsten steel strips

An automatic polishing, tungsten steel technology, applied in grinding/polishing equipment, surface polishing machine tools, metal processing equipment, etc., can solve problems such as high requirements for operators' skills and quality, difficulty in ensuring product quality, and great physical harm. Achieve the effect of avoiding splashing, improving the degree of automation, and ensuring the quality of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

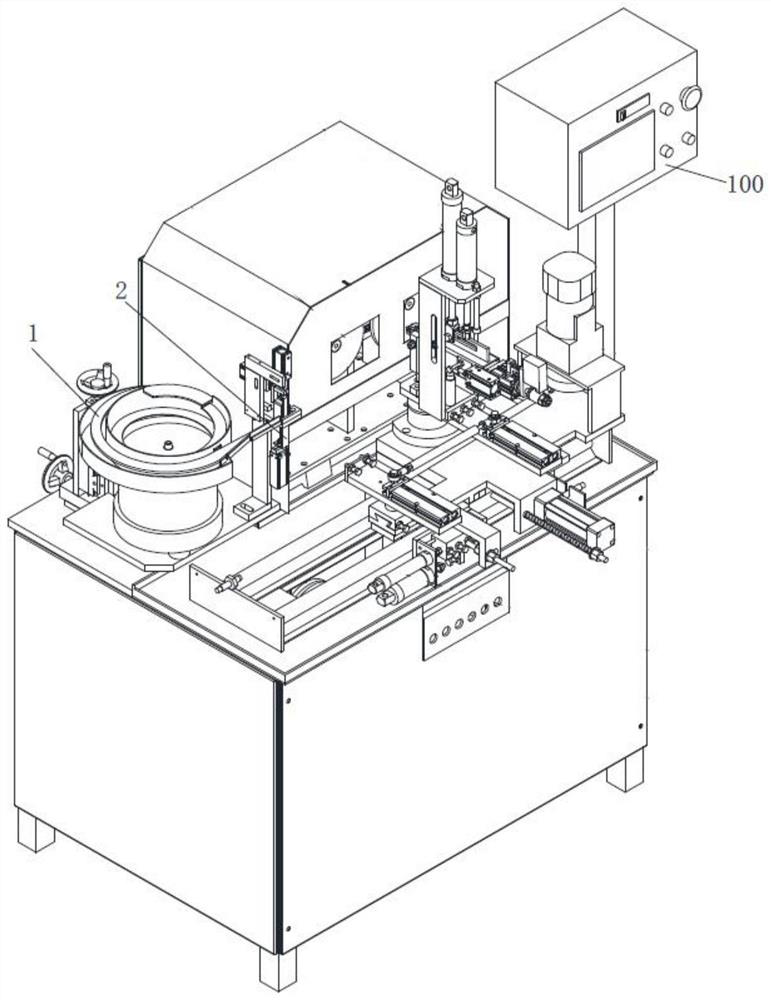

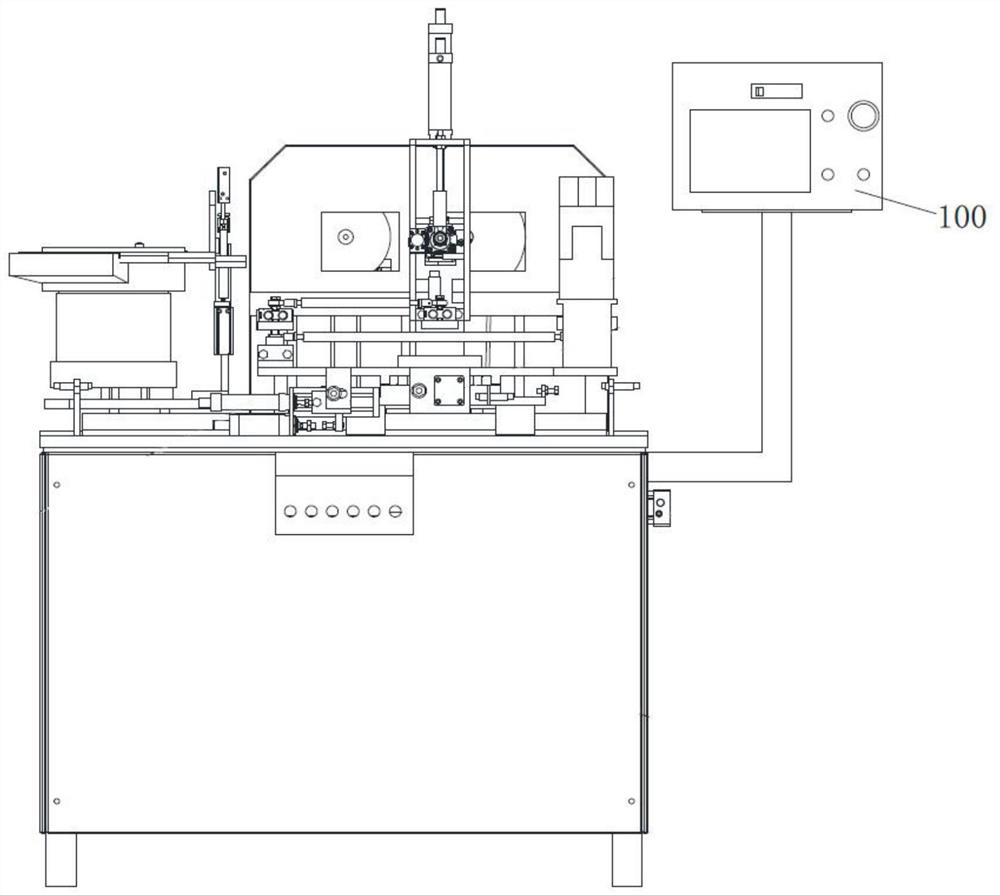

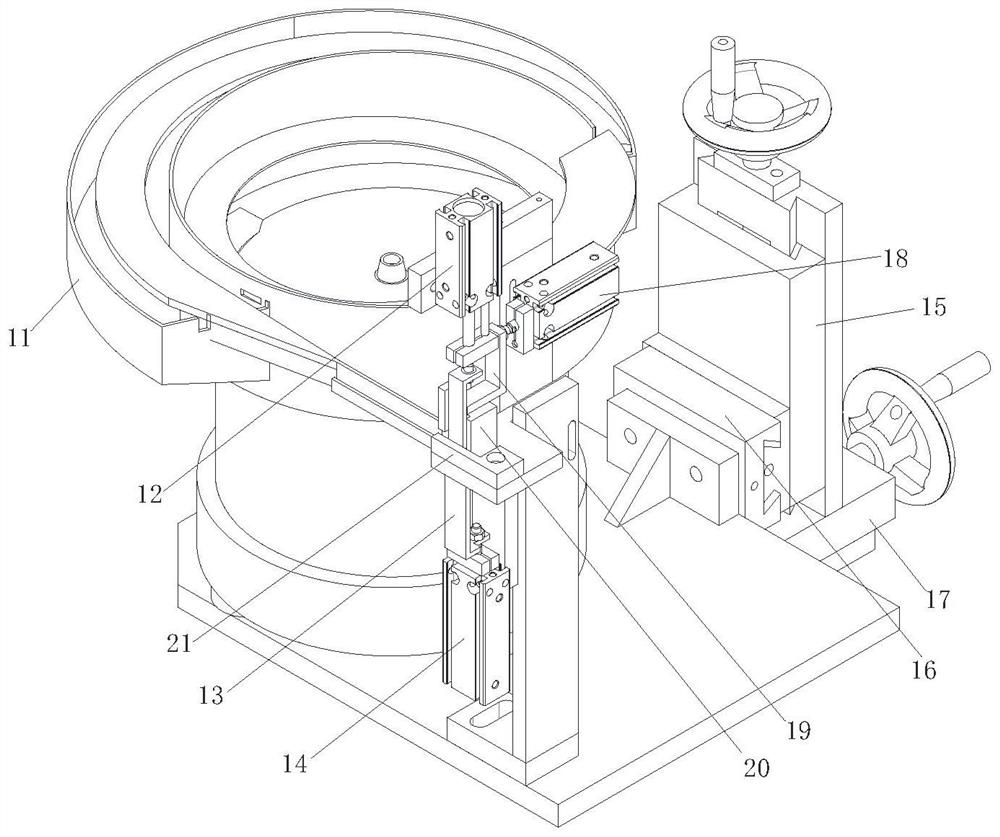

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Please refer to Figure 1-11 , in this implementation: refer to figure 1 , figure 2 , image 3 , the feeding mechanism 1 of the tungsten steel strip grain automatic polishing equipment structure of the present invention includes a vibrating plate 11 installed on the frame and executing the instructions of the controller 100, the vibrating plate 11 is fixed on the vibrating plate supporting plate, and the vibrating plate supporting plate Respectively connected with the first dovetail slide 15, the second dovetail slide 16, and the third dovetail slide 17, so that the feeding mechanism 1 can perform X-axis, Y-axis, Z All shafts can adjust the distance position; the upper top support block 13 with grain connected with the vibrating plate 11, the lower pressure support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com