Device special for ham flower cutting in catering industry

A technology of ham in the catering industry, which is applied in the field of ham cut flowers in the catering industry, which can solve the problems of uneven cut flowers and only one ham cut flowers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

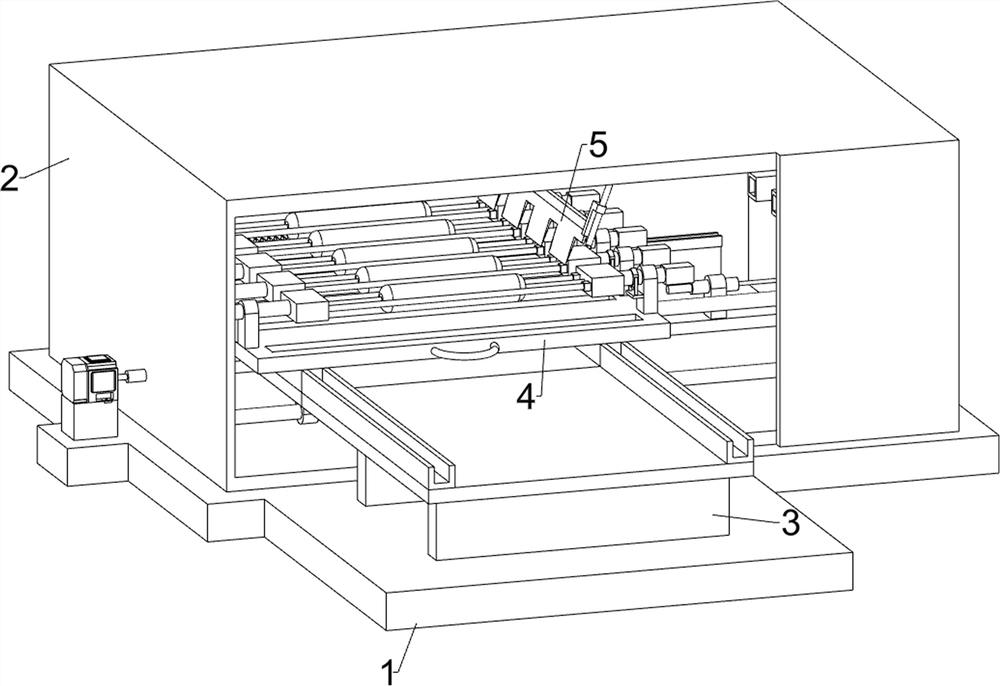

[0024] Such as figure 1 As shown, a device dedicated to cutting ham in the catering industry includes a base 1, a casing 2, a support block 3, a moving mechanism 4, and a cutting mechanism 5. The casing 2 is arranged on the rear side of the base 1, and the front side of the base 1 is arranged There is a support block 3 , a moving mechanism 4 is arranged in the casing 2 , a cutting mechanism 5 is arranged in the casing 2 , and the cutting mechanism 5 is located above the moving mechanism 4 .

[0025] When the staff needs to use this device, the staff needs to string some hams to be cut on the moving mechanism 4, then push the moving mechanism 4 into the shell 2, and then start the moving mechanism 4, and the moving mechanism 4 moves back and forth on the shell 2 , when the moving mechanism 4 passes the cutting mechanism 5 with the ham, the movement of the moving mechanism 4 will drive the cutting mechanism 5 to move up and down, so that the ham to be cut is cut. Finally, the s...

Embodiment 2

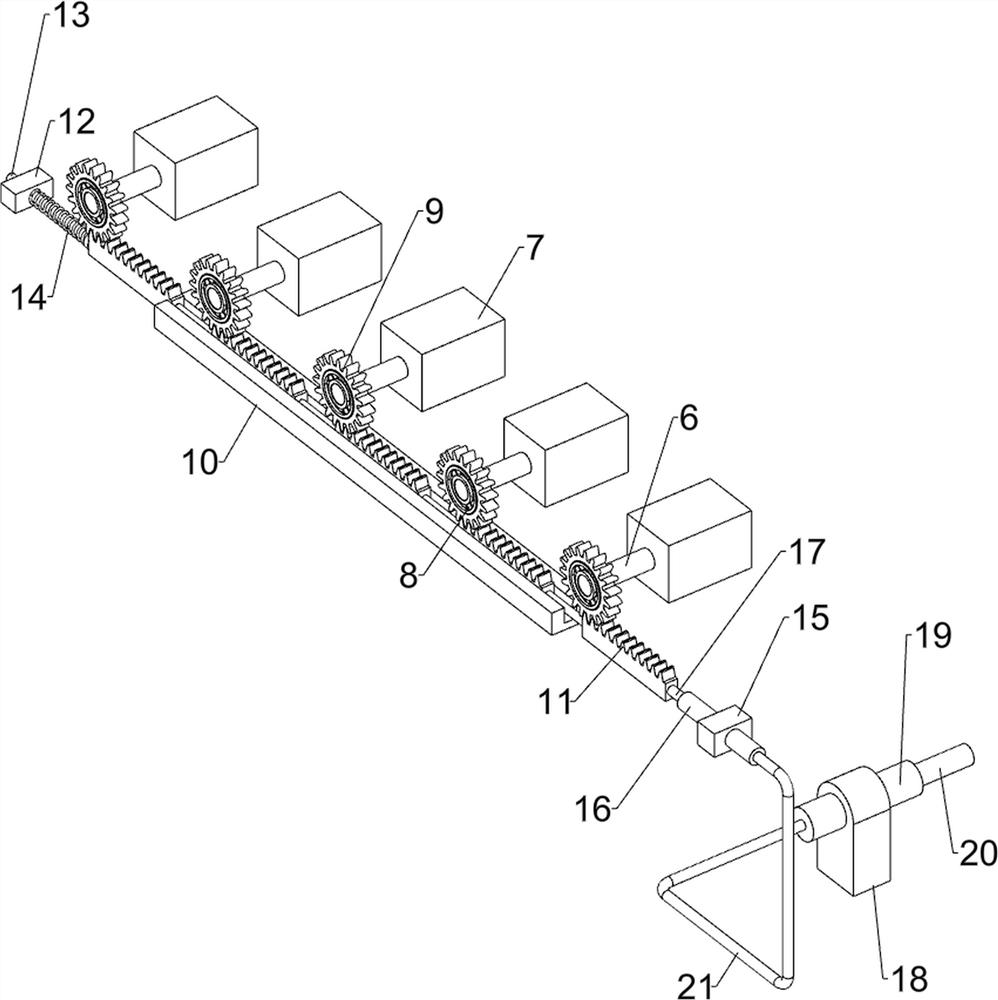

[0027] Such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, the moving mechanism 4 includes a first guide column 41, a moving plate 42, a first slide rail 43, a nut block 44, a screw mandrel 45, a track 46, a placement plate 47, and a bearing seat 48. The first rotating shaft 49, the insertion rod 410, the sleeve block 411, the square shaft 412, the hexagonal block 413, the spring clip 414, the handle and the servo motor 415, and the first guide post 41 is symmetrically arranged in the shell 2, and the first The guide post 41 is slidably provided with a moving plate 42, the moving plate 42 is symmetrically provided with a first slide rail 43, the middle part of the lower side of the moving plate 42 is provided with a nut block 44, and the middle part of the housing 2 is rotatably provided with a screw mandrel 45. Rod 45 cooperates with nut block 44, and support block 3 is provided with track 46, and track 46 cooperates with the firs...

Embodiment 3

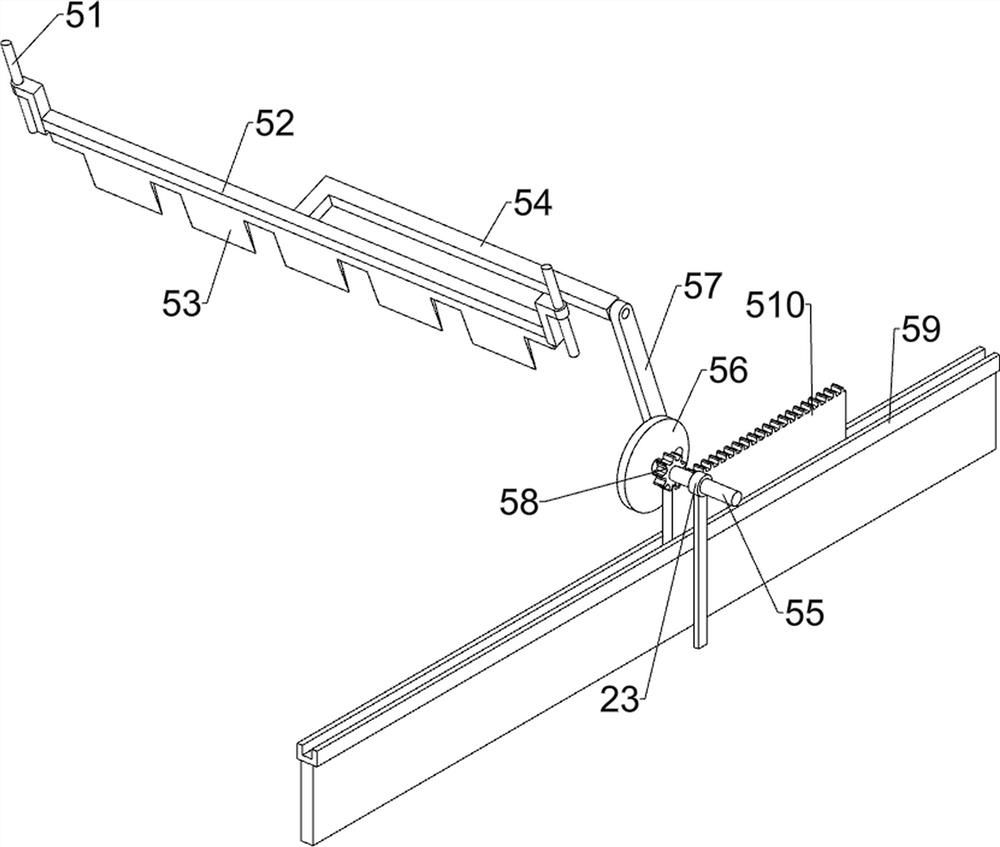

[0032] Such as Figure 6 and Figure 7 As shown, on the basis of Embodiment 2, it also includes a third rotating shaft 6, a square sleeve 7, a one-way bearing 8, a second circular gear 9, a third slide rail 10, a second rack 11, and a guide block 12 , pressure column 13, elastic member 14, fixed block 15, first cylinder 16, first piston rod 17, fixed seat 18, second cylinder 19, second piston rod 20, conduit 21 and top block 22, right side The inner walls of the shell 2 are evenly spaced and rotated to be provided with a third rotating shaft 6, the left end of the third rotating shaft 6 is provided with a square sleeve 7, the right end of the third rotating shaft 6 is provided with a one-way bearing 8, and the outer wall of the one-way bearing 8 is provided with a The second round gear 9 is provided with a third slide rail 10 between the inner walls of the housing 2 on the right side, and a second rack 11 is slidably arranged in the third slide rail 10, and the second rack 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com