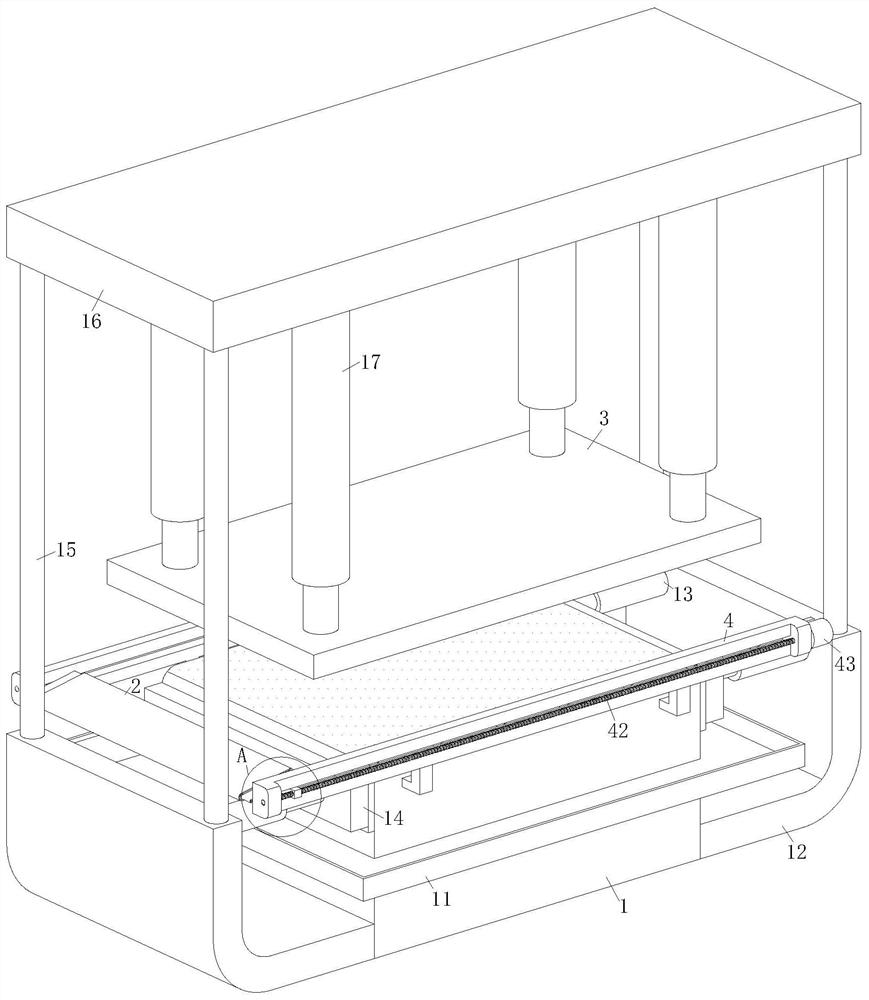

Reflective film production device and production method

A technology for producing devices and reflective films, which is applied to optical components, other household appliances, household appliances, etc., can solve the problems of uneven distribution of glass microbeads, affecting the reflective properties of reflective films, affecting the use effect, etc., to improve the practical application effect. , the effect of improving the level of automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

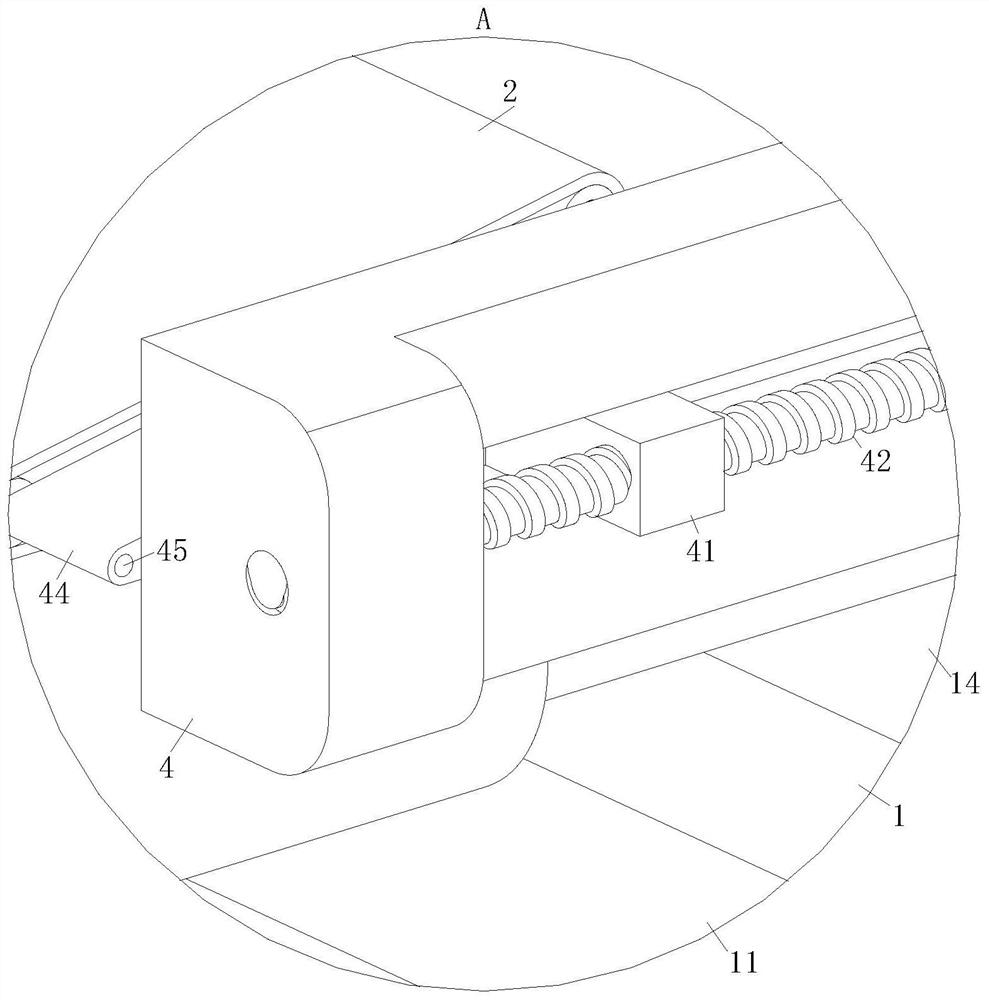

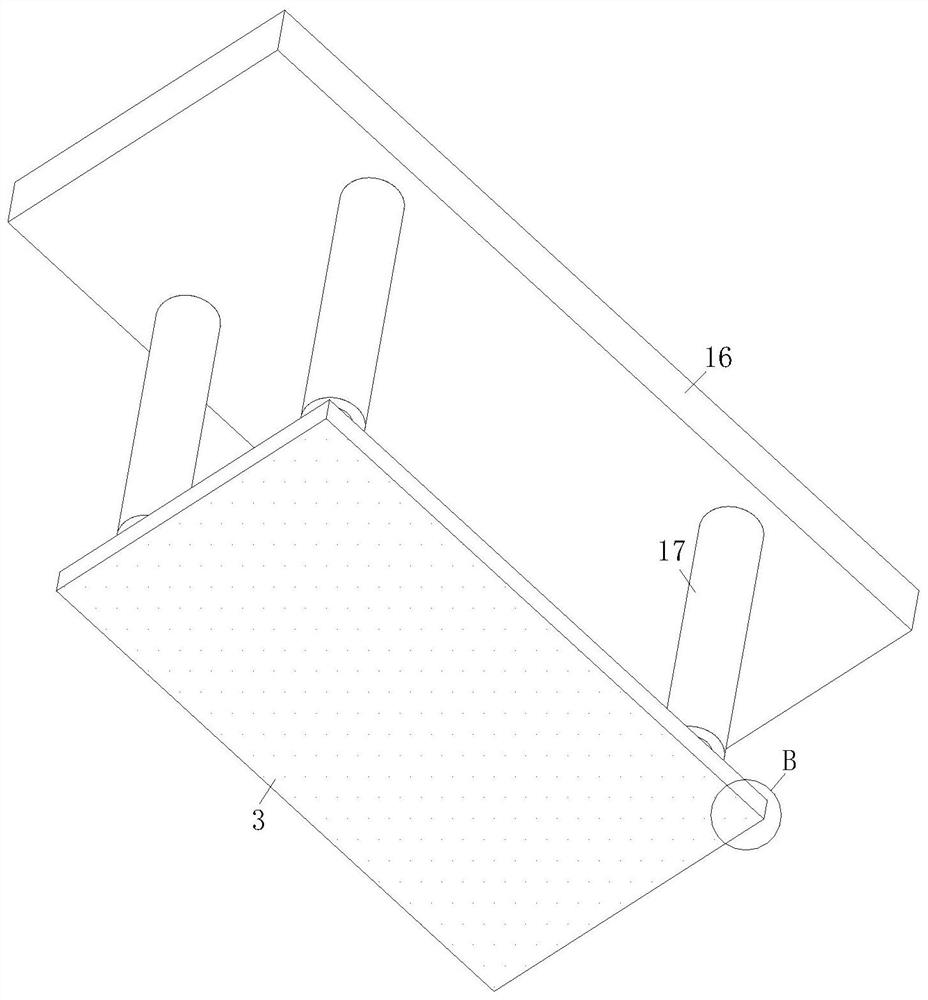

[0033] As an embodiment of the present invention, one side of the support plate 5 is fixedly connected with an arc-shaped rod 51, the blocking rod 61 is slidably connected with the arc-shaped rod 51, and the arc-shaped rod 51 is covered with a No. 1 spring 52 The No. 1 spring 52 is located between the support plate 5 and the stop rod 61; during work, if the glass microspheres are not filled in the pit, the glass microspheres cannot rub against the belt 2, so that the belt 2 cannot drive the barrel 6 motion, cause the ineffectiveness of reflective film production device; Therefore in the process that rolling bar 45 of the present invention and belt 2 move from one end of screw rod 42 to the other end, belt 2 is not subject to glass microsphere friction force, because one side of support plate 5 Fixedly connected with an arc rod 51, the arc rod 51 is covered with a No. 1 spring 52, and the retaining rod 61 is slidably connected to the arc rod 51, so the retaining rod 61 is subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com