PMMA-type two-component marking paint, environmentally friendly and durable two-component marking material using the paint and its construction method

A kind of marking paint, two-component technology, applied in anti-corrosion paint, reflective/signal paint, coating, etc., can solve the problems of marking mark's recognizability and insufficient durability, achieve good reflective performance and improve durability And the effect of identification and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

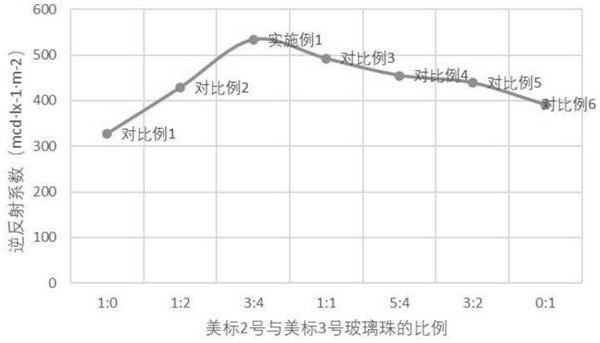

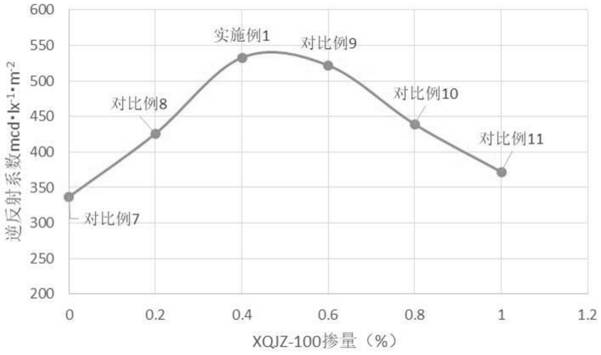

Embodiment 1

[0068] Divide the high-efficiency thickener XQZJ-100 (according to mass percentage: 85% organic bentonite, 10% organic kaolin, and 5% fumed silica) of 0.4% of the total amount of paint into two equal parts, and add them to groups A and B respectively After stirring evenly, add 2% benzoyl peroxide of the total amount of paint to component B and stir evenly with an electric mixer at low speed, put component A and component B added with 2% benzoyl peroxide In different containers isolated from each other, mix components A and B at a ratio of 1:1 as evenly as possible, and apply it on the test panel. Add American Standard No. 2 glass beads and American Standard No. 3 glass beads with a roundness rate of 90% and a refractive index of 1.9 into the corresponding hoppers, and adjust the output ratio to 3:4. Sprinkle the glass beads on the surface before the paint solidifies. Sprinkle the beads on the surface of the coating. Specifically, first sprinkle the American Standard No. 3 glas...

Embodiment 2

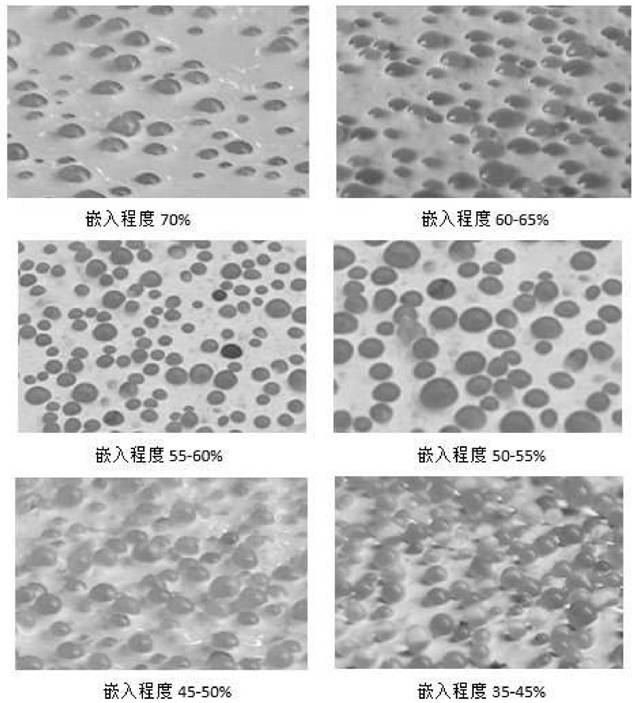

[0101] According to the composition of the paint and surface sprinkle glass beads described in Example 1 and the surface sprinkle amount forming marking line, under the conditions of different temperatures and different curing agent dosages, with the embedding degree between 55%-65% as the target, determine different The optimum dosage of curing agent at the temperature is shown in Table 3 for the results.

[0102] Table 3 Curing agent dosage at different temperatures

[0103] Ambient temperature (℃) 5℃ 10℃ 15℃ 20℃ 25℃ 30℃ 35℃ Curing agent dosage (%) 3.7 3.7 2.9 2.4 2.0 1.75 1.4

[0104]When constructing the marking line, you can refer to the local climate conditions and choose the appropriate amount of curing agent to achieve the best hardening time and retroreflection coefficient of the marking line.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com