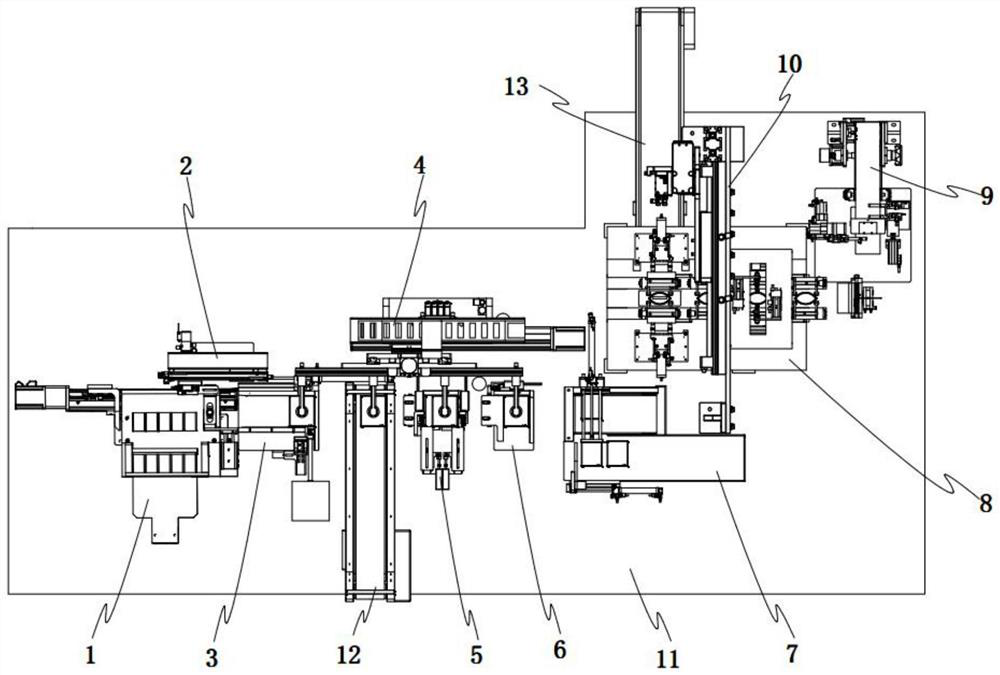

Electric power battery panel detecting and packaging machine

A battery board and packaging machine technology, applied in packaging, measuring devices, transportation packaging, etc., can solve problems such as hidden dangers, waste and damage of packaging bags, low detection efficiency, etc., to improve product detection and packaging efficiency, and reduce labor input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

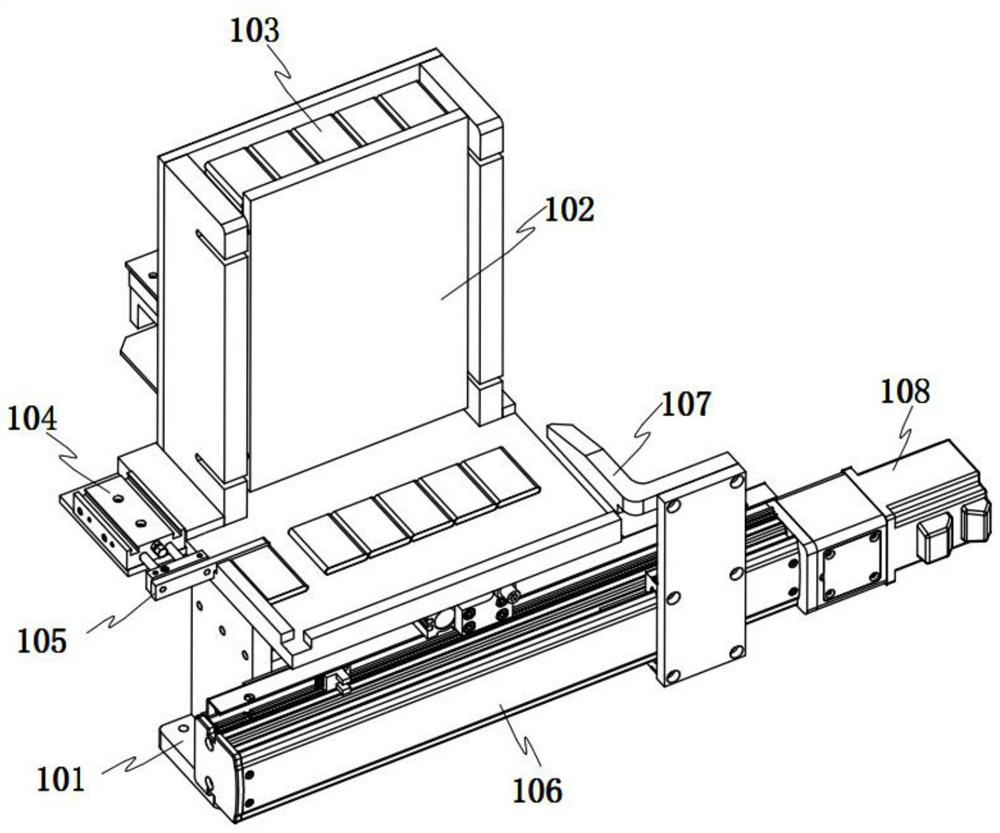

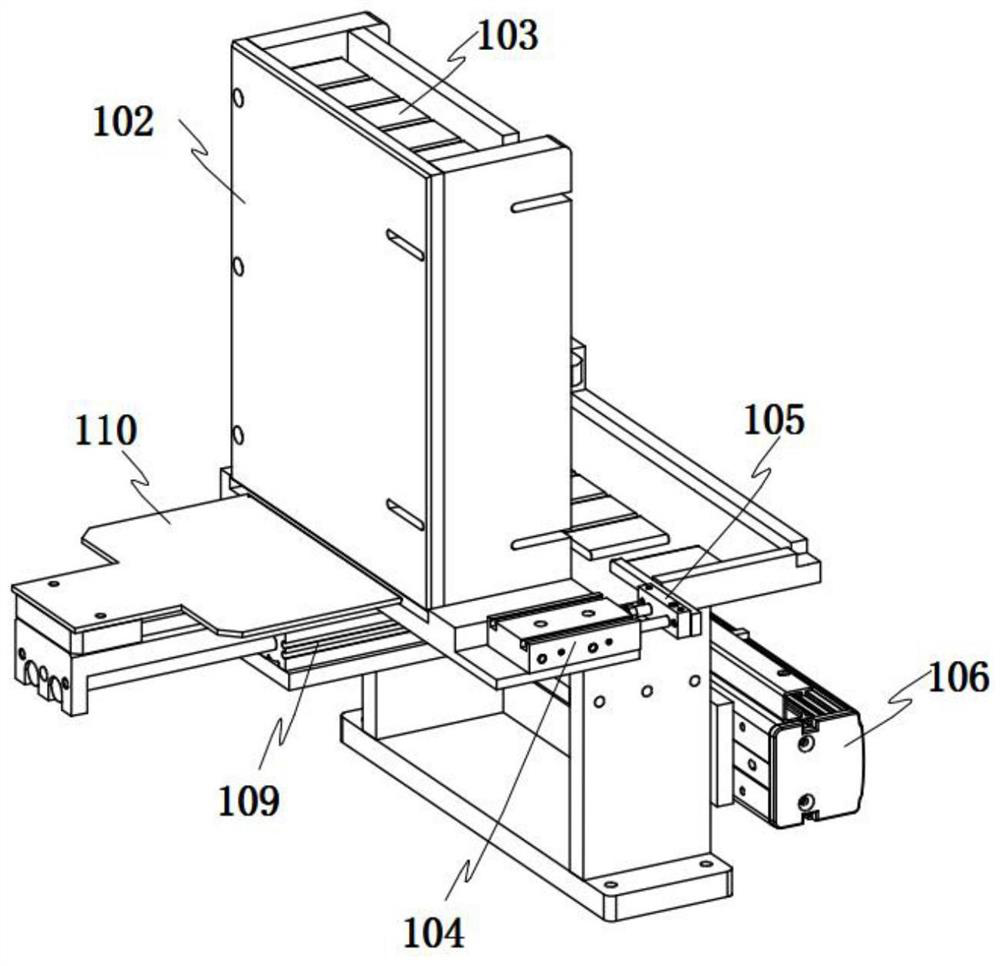

[0046] When the detection and packaging machine is working, the push-out cylinder 109 of the battery board storage and push-out mechanism 1 first drives the push-out board body 110 to pass through the lower end of the battery board storage frame 102, and pushes the battery board 103 in the battery board storage frame 102 out to the storage and ejection position. The front side of the top of the seat 101, and then the displacement drive motor I108 drives the horizontal push plate 107 to slide along the push rail 106, so that the pushed out battery panel 103 is pushed laterally to the designated position by the horizontal push plate 107, and then the vertical push cylinder I104 drives the vertical The push plate 105 pushes the battery board 103 longitudinally to the input position, and then the displacement drive motor II 202 of the battery board input mechanism 2 drives the displacement installation block 205 to move along the parallel guide rod 203 to the upper part of the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com