Adjustable metal opposite-pull piece and shaping combined formwork

An adjustable, metal technology, applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of labor-intensive welding process, affecting construction quality, affecting construction progress, etc. , to achieve the effect of reducing construction cost, reasonable structure and speeding up construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the described embodiments are only a part of the embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all those skilled in the art can obtain without creative work. Other embodiments all belong to the protection scope of the present invention.

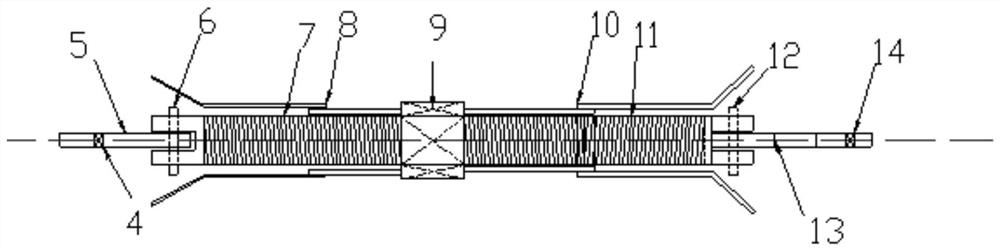

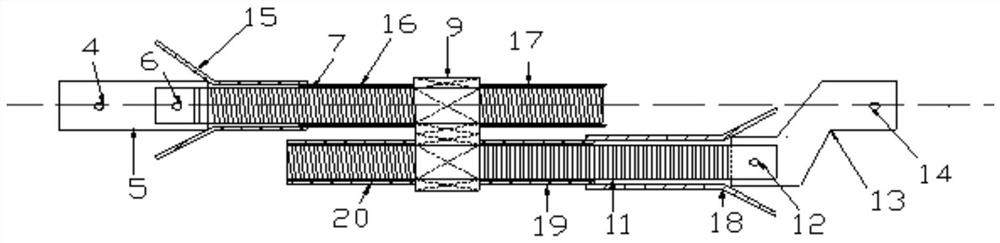

[0036] see Figure 1a with Figure 1b , In one embodiment of the present invention, an adjustable metal pull-tab is provided. Specifically, the adjustable metal pull-tab includes: a first pull-tab body 5 , a first adjustment screw 7 , a two-way double-hole internal thread sleeve 9 , a second adjustment screw 11 and a second pull-tab body 13 . Wherein, one side of the first pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com