An electrothermal driver with ultra-fast response speed and its preparation method

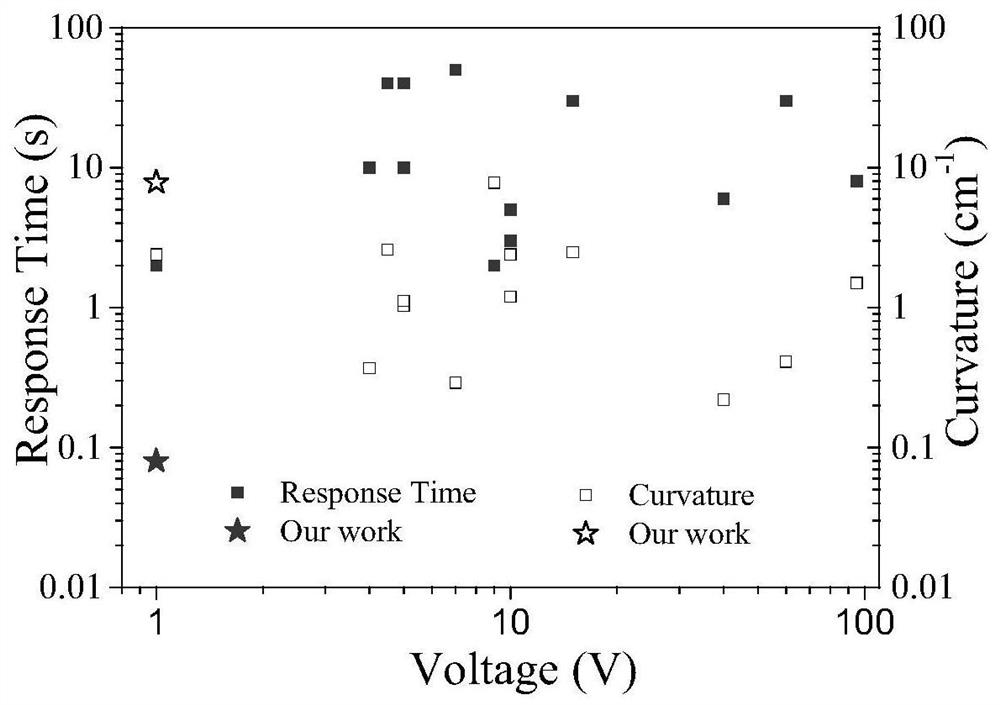

A response speed, driver technology, applied to the conductive layer on the insulating carrier, mechanical equipment, machines/engines, etc., can solve the problems of slow response speed, high driving voltage, and unsatisfactory electrothermal driving performance of electrothermal drivers. Achieve the effect of excellent response speed, fast response speed and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Fresh AgNO 3 (0.9 g) was added to 20 mL of ethylene glycol and mixed ultrasonically in an ice-water bath at 4-8°C for 5-6 minutes until completely dissolved. CuCl 2 2H 2 O (0.0132 g) was dissolved in 16 mL of ethylene glycol. PVP (K30, 0.421 g) and PVP (K90, 0.406 g) were dissolved in 115 mL of ethylene glycol and heated at 130 °C for 25 minutes to achieve complete dissolution, then heated to 140 °C in a 250 mL flask in an oil bath. Subsequently, within 5 minutes, 3.2 mL of CuCl 2 solution and 20mL AgNO 3 The solution was added dropwise to the PVP solution. The reaction was held for 50 minutes. After the reaction was completed, the flask was removed from the oil bath and the solution was quenched to room temperature, and the obtained product was crude silver nanowires.

Embodiment 2

[0030] Prepare (A) 220.0 mM NaBr, (B) 210.0 mM NaCl and (C) 505.0 mM PVP K90 in ethylene glycol. Ethylene glycol (116mL), solution A (1mL), solution B (2mL), solution C (15mL) and fresh AgNO 3 (0.6765 g in 15 mL ethylene glycol) was added to a 250 mL flask in an oil bath at room temperature. Then the solution was heated at 300rpm min -1 Stir mechanically for 30 min. After stirring, the temperature of the oil bath was slowly raised to 180°C over 20-25 minutes. At the same time, during the heating process, nitrogen (150mL min -1 ) into the solution. When the temperature reached 180°C, the nitrogen was turned off and the temperature of the oil bath was set to 170°C. After 10 minutes, stirring was stopped and the reaction was maintained for 1 hour. After the reaction was completed, the flask was removed from the oil bath and the solution was cooled to room temperature in water, and the obtained product was crude fine silver nanowires.

Embodiment 3

[0032] Both crude silver nanowires and crude silver nanowires were purified by dynamic stirring-induced centrifugal purification. The prepared silver nanowire crude product was mixed with deionized water, and then poured into a filter membrane cylindrical chamber with holes (8 μm), and the maximum speed of the mechanical stirrer was set at 900 rpm with a six-hole stirring paddle. Deionized water was continuously flowed into the filter unit to compensate for the removed filtrate solution and to maintain a stable silver nanowire concentration in the feed solution. After purification (60 minutes), the continuous addition of deionized water was stopped while stirring and rinsing continued to concentrate the solution to the desired concentration of silver nanowires. Purified silver nanowires were collected from the bottom of the filter-membrane-based cylindrical chamber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com