Engineering vehicle wheel-side speed reducer and mining dump truck

A technology for wheel-side deceleration and engineering vehicles, which is applied in the direction of mechanical equipment, gear transmission, gear lubrication/cooling, etc. It can solve the problems of low maintenance efficiency, reduced reliability of gearboxes, and poor maintenance performance, so as to improve reliability Excellent safety, stability and reliability, good reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

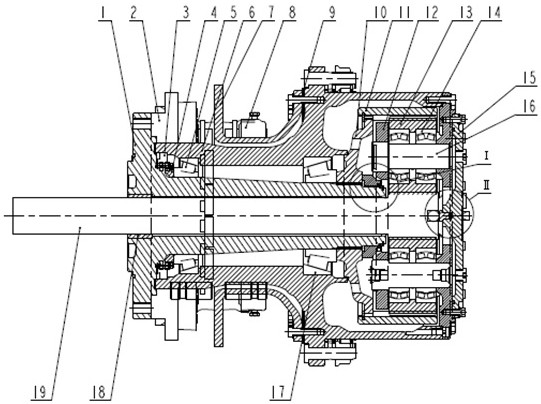

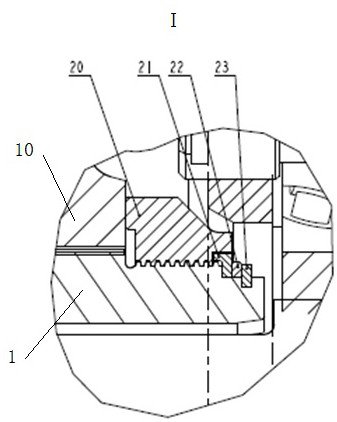

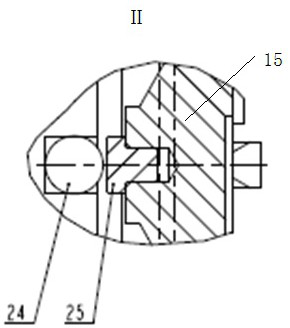

[0032] Such as Figure 1 to Figure 4 The shown engineering vehicle wheel reducer includes a half shaft 19, and the half shaft 19 is provided with a half shaft sleeve 1, and one end of the half shaft sleeve 1 is connected with a brake mounting plate 2, and the half shaft sleeve The other end of the pipe 1 is connected with a ring gear bracket 10, and the ring gear bracket 10 is connected with a ring gear 11, and a planetary gear 13 is arranged between the ring gear 11 and the half shaft 19, and the planetary gear 13 is connected by a pin The shaft 16 is connected with a planetary carrier 12, and the planetary carrier 12 is arranged on the hub 6; a box seal 3 is provided between the hub 6 and the half shaft sleeve 1; the outer circumference of the half shaft sleeve 1 is also provided with The supporting bush 18, the inner hole of the supporting bush 18 is processed with an annular oil groove; the slot hole at the end of the half shaft 19 is provided with a steel ball 24, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com