Module structure for supercharging of gas field supercharging station

A technology of modular structure and booster station, which is applied in the direction of gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., which can solve the problems of long cycle and achieve the effect of rapid commissioning, shortening commissioning time and reducing project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

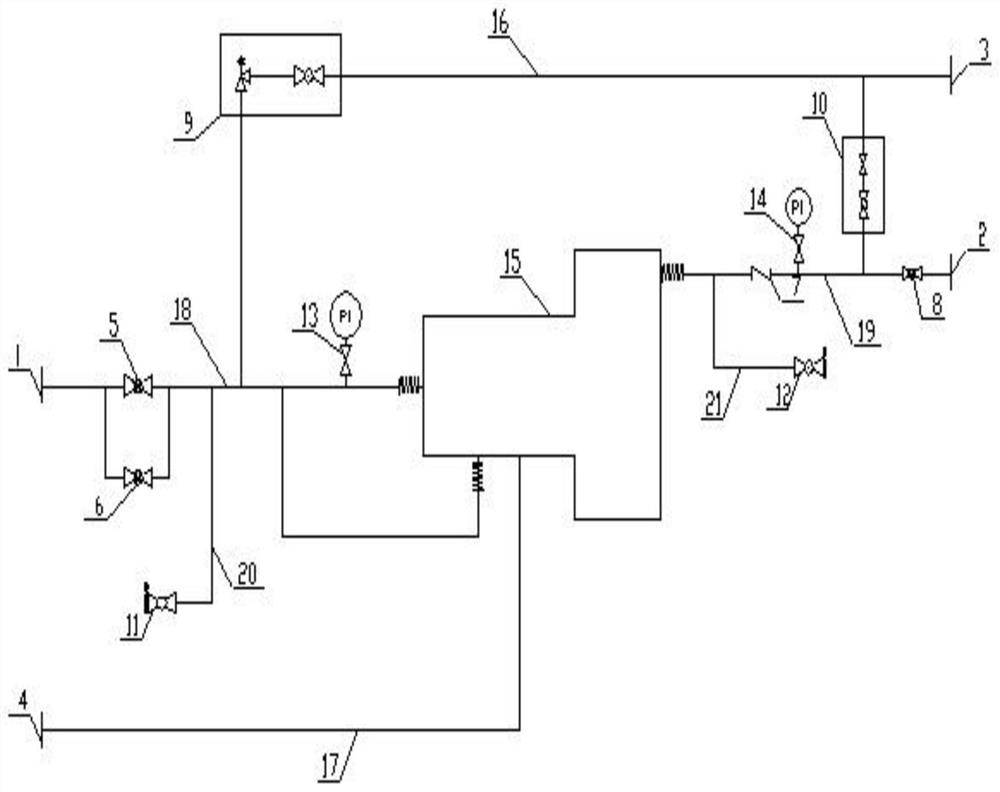

[0023] Such as figure 1 As shown, a modular structure for supercharging of a gas field supercharging station includes an air inlet 1, an air inlet pipeline 18, an air inlet valve 5, a natural gas compressor 15, an air outlet valve 8, an air outlet 2 and an air outlet pipeline 19, and the air inlet The port 1 and the inlet valve 5 are connected to the inlet of the natural gas compressor 15 through the inlet pipeline 18 in turn, and the outlet of the natural gas compressor 15 is connected to the gas outlet valve 8 and the gas outlet 2 through the gas outlet pipeline 19 in sequence.

[0024] The gas coming from the pigging area in the pressurization station passes through the inlet 1, and enters the natural gas compressor 15 through the inlet pipeline 18 through the inlet valve 5 for pressurization. After the pressurization, the natural gas enters the downstream process of the station through the outlet valve 8 and the outlet 2; It realizes pressurization function, compact struct...

Embodiment 2

[0026] On the basis of Embodiment 1, a balance valve 6 is further included, and the balance valve 6 and the intake valve 5 are connected in parallel through pipelines. The balance valve 6 adjusts the pressure balance before the intake valve 5 and the valve group during intake air, so as to improve the safety of pipeline equipment.

[0027] Further, a gas outlet check valve 7 is also included, and the gas outlet check valve 7 is connected to the gas outlet pipeline 19 between the natural gas compressor 15 and the gas outlet valve 8 . The air outlet check valve 7 prevents the backflow of the air outlet, plays the role of safety isolation, and prevents accidents from happening.

[0028] Further, it also includes a safety vent valve group 9, a vent pipeline 16 and a vent port 3, one end of the safety vent valve group 9 is connected to the intake line 18 between the intake valve 5 and the natural gas compressor 15, and the safety vent valve group The other end of 9 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com