Rotary waste heat recycling device

A waste heat recovery and rotating technology, which is applied in the direction of cleaning heat transfer devices, rotating equipment cleaning, moving duct heat exchangers, etc., can solve the problem of low flue gas recycling rate, inability to effectively remove scale inside equipment, and flue gas residence time Short and other problems, to achieve the effect of saving enterprise costs, improving scale removal efficiency, and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

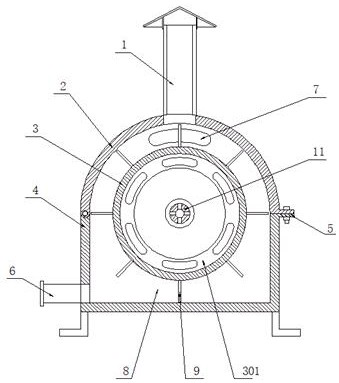

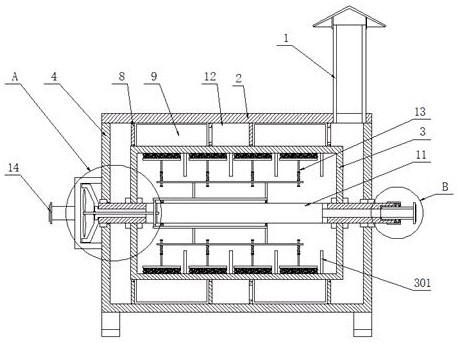

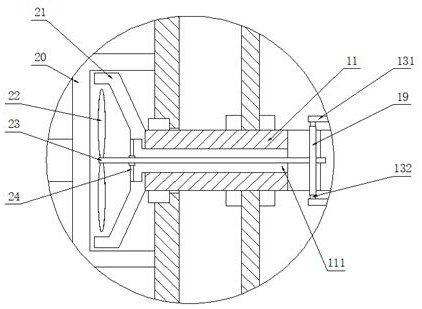

[0027] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0028] A rotary waste heat recovery and utilization device, including a box cover 2, a heat recovery cylinder 3 and a heat insulation box 4, one side of the box cover 2 is rotated and installed in the heat insulation box 4, and the other side of the box cover 2 is passed through The locking buckle 5 is fixedly connected with the heat insulation box 4, and the shaft center at both ends of the heat recovery cylinder 3 is fixed with a rotating shaft 11, and a scale scraping mechanism 13 is installed on the rotating shaft 11 inside the heat recovery cylinder 3, and the two ends of the rotating shaft 11 are respectively The two ends of the heat insulation box 4 are rotatably connected by bearings, and one end of the heat insulation box 4 is fixed with a water inlet chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com