Multi-motor disc suspension control system and method

A suspension control, multi-motor technology, applied in the control system, motor generator control, control using feedback, etc., to achieve the effect of obvious parameter adjustment, low power consumption, flexible installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

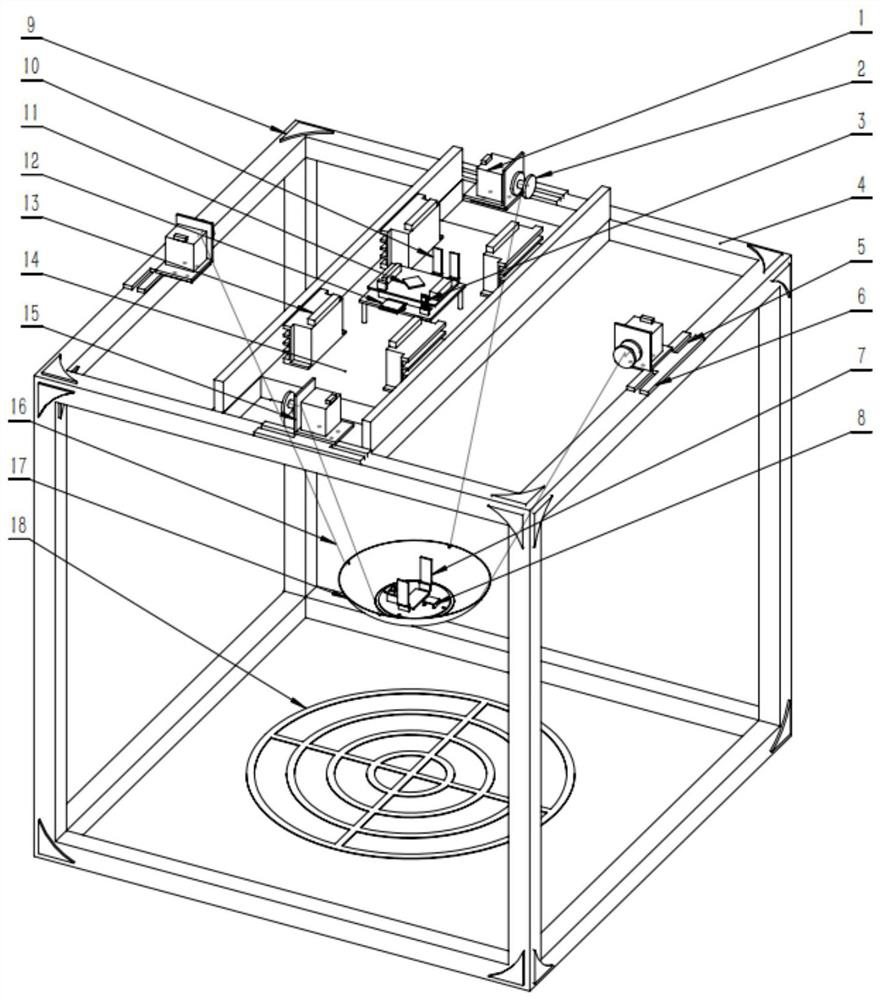

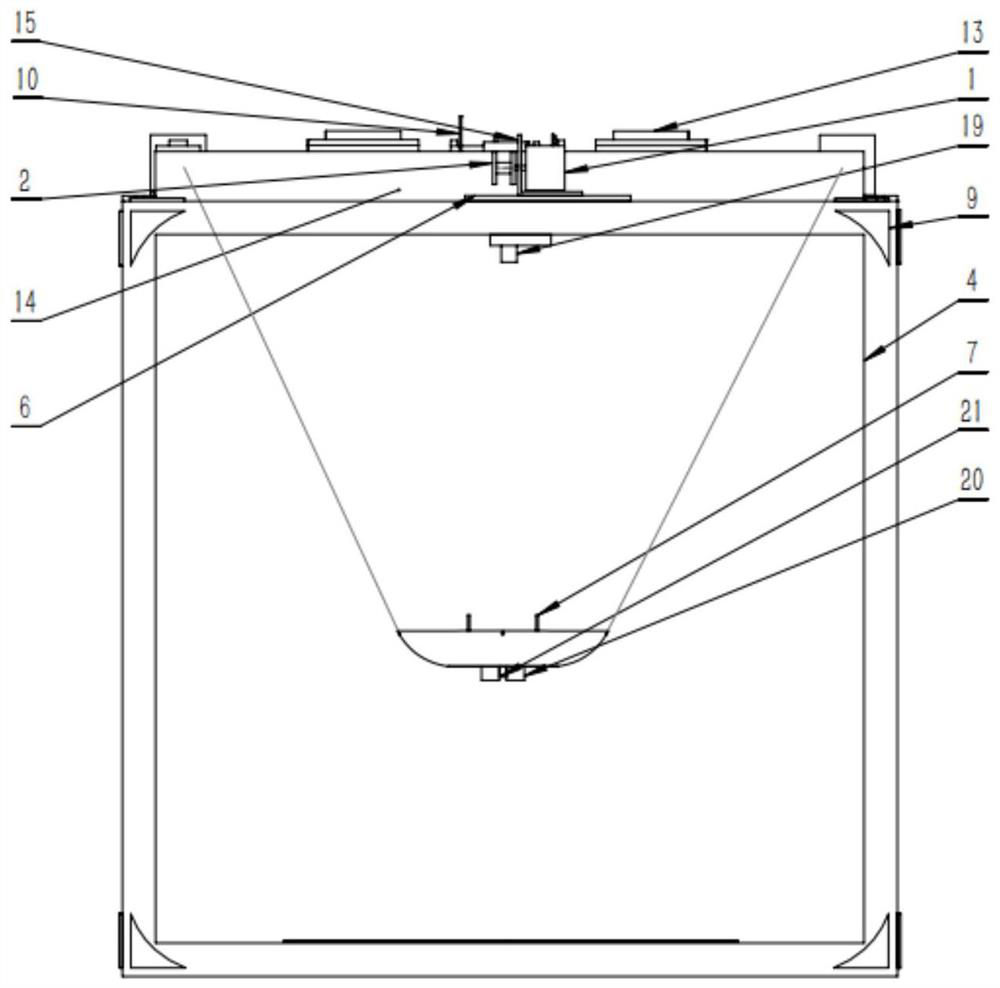

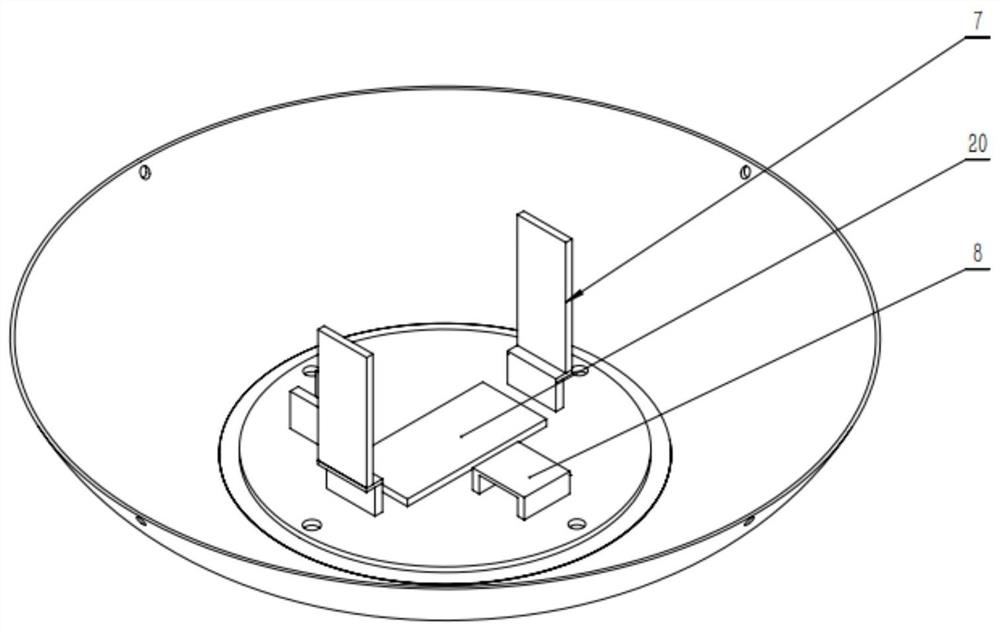

[0053] like figure 1 , figure 2 , image 3 As shown, a multi-motor disk suspension control system is mainly composed of a motor 1, a coupling 2, a remote control module 3, a support frame 4, a motor base 6, a wireless communication host module 7, an angle measurement module 8, a wireless communication slave Machine module 10, main control module 11, display module 12, drive module 13, beam 14, motor bracket 15, traction rope 16, disk system 17, target disk 18, image processing module 19, distance measuring module 20, laser pointer 21 constitute.

[0054] The supporting frame 4 is a three-dimensional structure with the upper bottom and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com