Capacitor bending and cutting device for processing electronic components

A technology of electronic components and cutting devices, which is applied in the manufacturing of electrical components, capacitors, capacitors, etc., can solve the problems of poor bending effect, inconvenient access, uncontrollable manual work force, etc., and achieves convenient transportation in collection boxes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

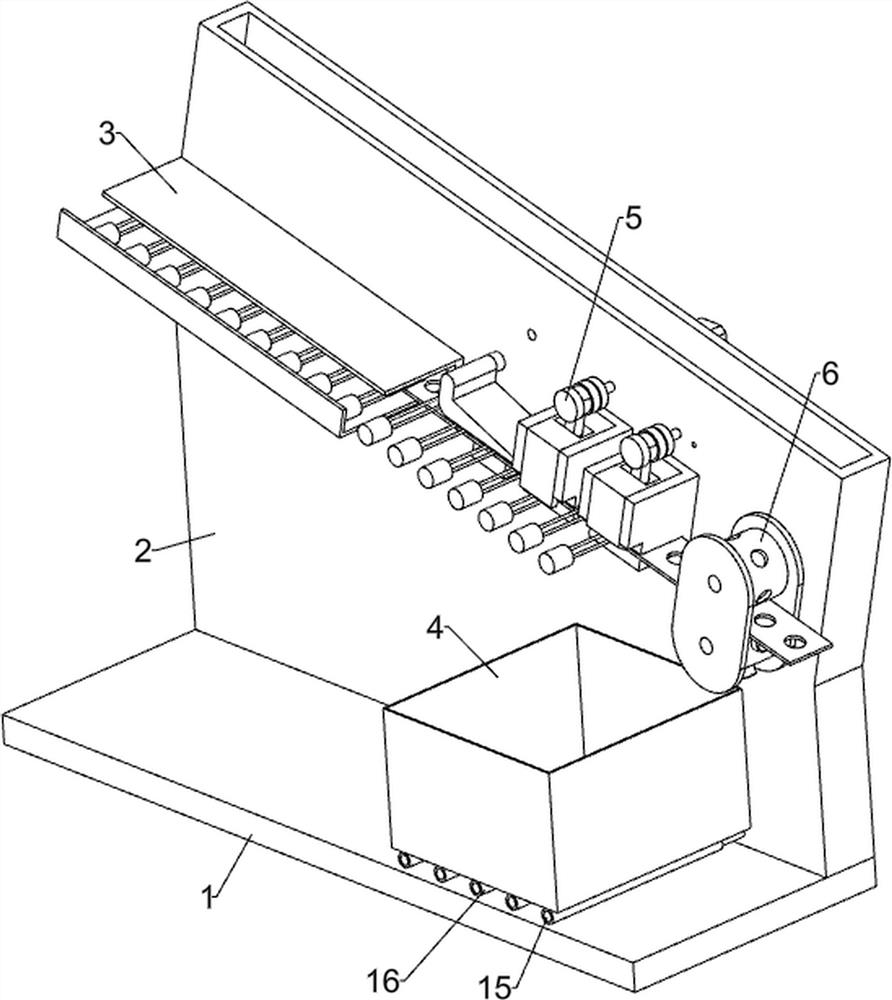

[0023] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a capacitor bending and cutting device for processing electronic components includes a base plate 1, a mounting frame 2, a blanking plate 3, a collection box 4, a bending and cutting mechanism 5, and a feeding mechanism 6. The rear side of the top of the base plate 1 is A mounting frame 2 is provided, a blanking plate 3 is provided on the left side of the mounting frame 2, a collection box 4 is placed on the top right side of the bottom plate 1, a bending and cutting mechanism 5 is provided on the mounting frame 2, and a feeding mechanism is provided on the mounting frame 2 6. The feeding mechanism 6 cooperates with the bending and cutting mechanism 5.

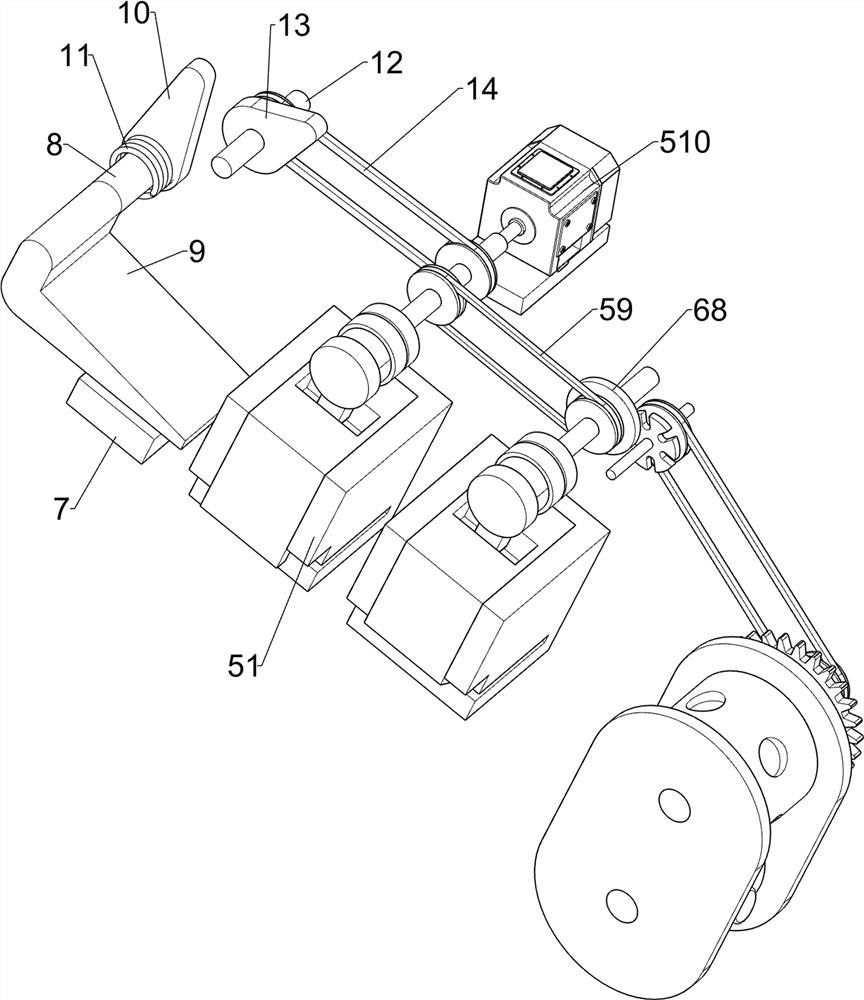

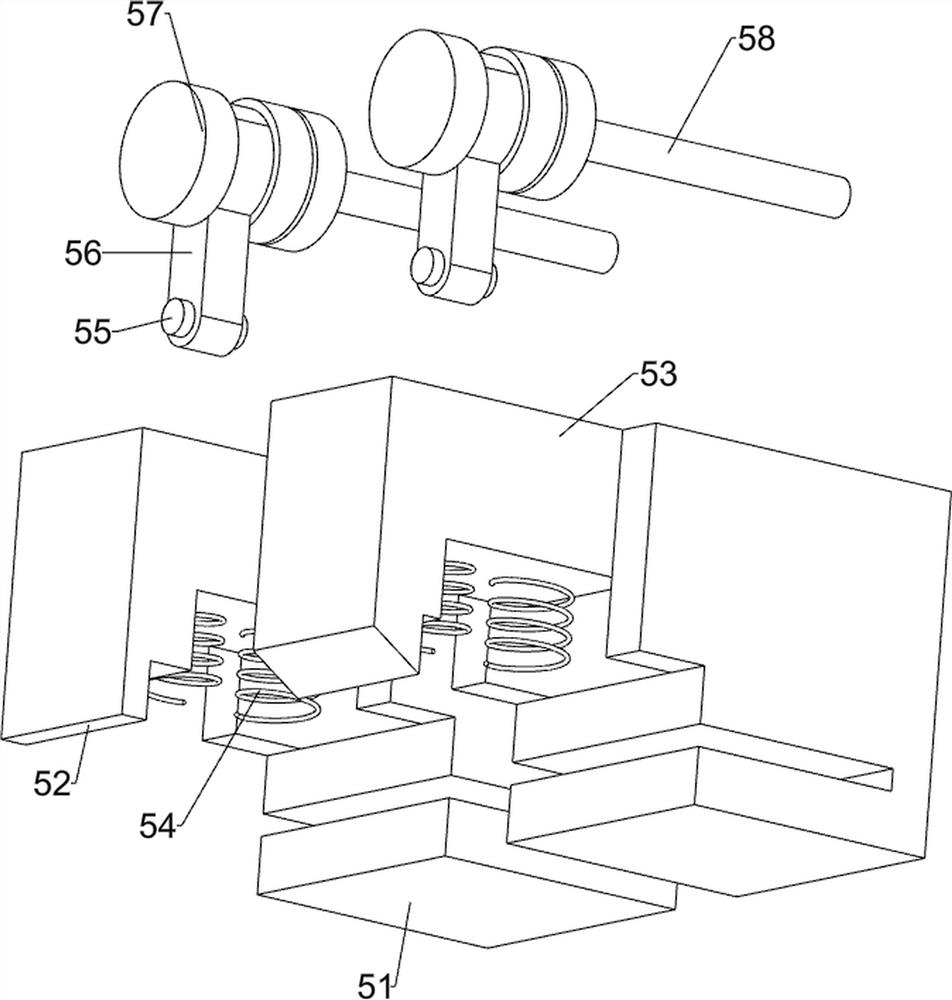

[0024] The bending and cutting mechanism 5 includes a fixed seat 51, a bending block 52, a cutting block 53, a first elastic member 54, a first rotating shaft 55, a crank 56, a round block 57, a second rotating shaft 58, a first belt transmission mechan...

Embodiment 2

[0028] Such as figure 1 with figure 2 As shown, on the basis of Embodiment 1, a capacitor bending and cutting device for processing electronic components also includes a bump 7, a fifth rotating shaft 8, a pressing block 9, a first cam 10 and a second elastic member 11 , the mounting frame 2 is provided with a bump 7 at a position close to the blanking plate 3, and the mounting frame 2 is provided with a fifth rotating shaft 8 rotating above the bump 7, and a pressing block 9 is arranged on the fifth rotating shaft 8, and the pressing block 9 and The protrusion 7 cooperates, the first cam 10 is arranged on the rear side of the fifth rotating shaft 8 , and the second elastic member 11 is sleeved on the fifth rotating shaft 8 .

[0029] When the staff needs to perform capacitance bending and cutting, the staff puts the feeding belt with evenly spaced round holes into the blanking plate 3, the feeding belt is located between the bump 7 and the pressing block 9, and passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com