Powder metering system and control method thereof

A metering system and powder technology, which are applied in mixing operation control, chemical instruments and methods, mixing operation control devices, etc., can solve the problems of inaccurate dynamic metering, unstable discharge flow, accelerated powder outflow, etc. Impact, stable and uniform discharge, and stable discharge flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

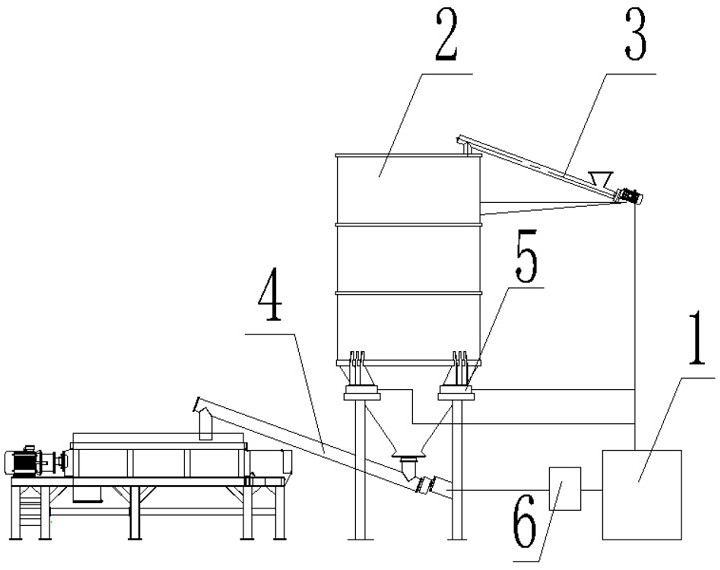

[0022] Such as figure 1 As shown, a powder metering system includes a control system 1: used to receive instructions and data, and generate control signals according to the instructions and data to control the feed device 3, the discharge device 4, the load cell 5, etc. operation, the control system 1 can adopt a PLC controller;

[0023] Weighing bin 2: used to store powder;

[0024] Feeding device 3: feed the powder;

[0025] Discharge device 4: discharge and convey the powder;

[0026] Load cell 5: measure the weighing bin and the powder in the weighing bin;

[0027] The discharging device 4 is electrically connected to the frequency converter 6 , and the feeding device 3 , the load cell 5 and the frequency converter 6 are all electrically connected to the control system 1 .

[0028] Both the feeding device 3 and the discharging device 4 are screw conveyors.

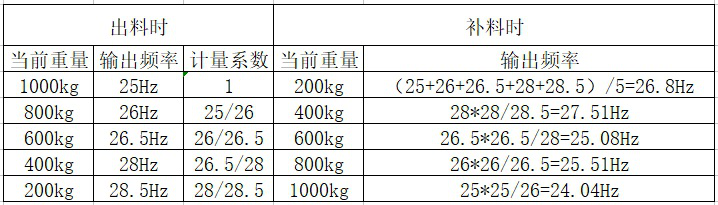

[0029] Such as figure 2 As shown, a control method for a powder metering system. When discharging, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com