A charging circuit and its control device and control method

A charging circuit and pre-charging technology, applied in battery circuit devices, circuit devices, DC network circuit devices, etc., can solve the problem of high equipment cost, and achieve the effect of reducing hardware equipment, ensuring safety, and reducing equipment failure points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

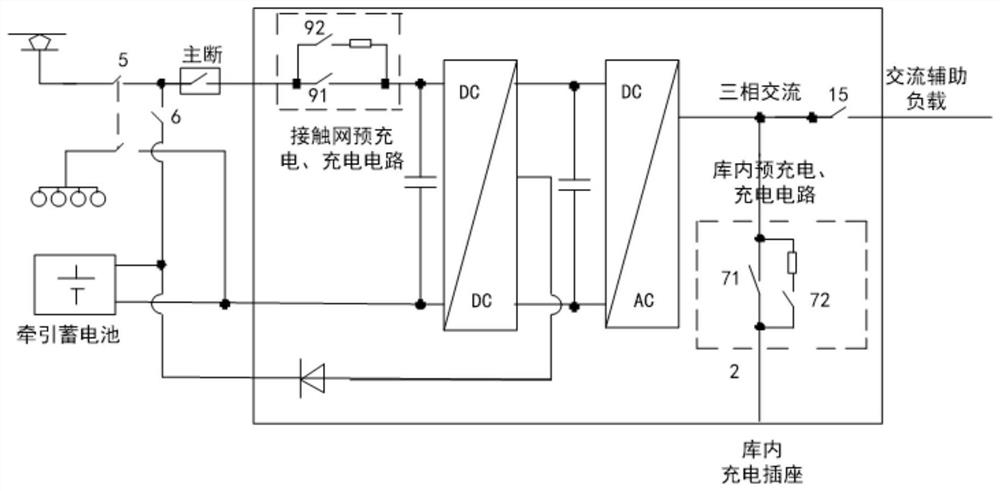

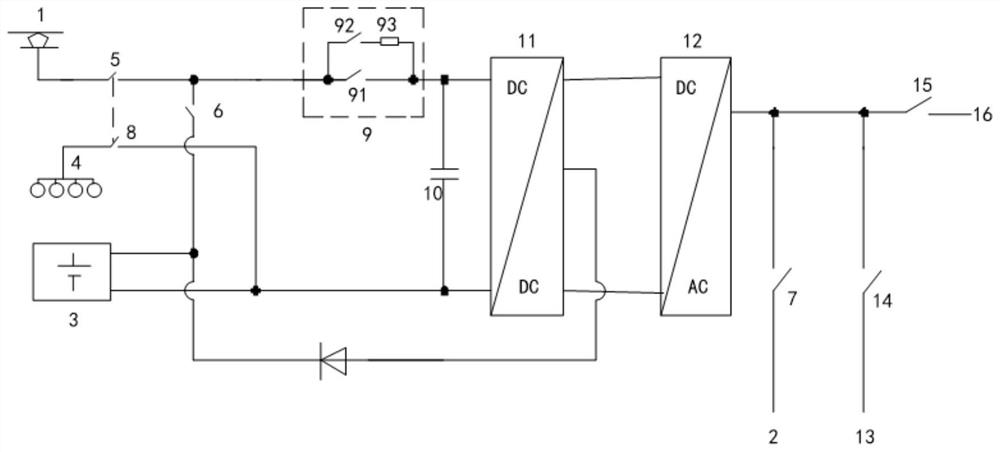

[0044] Such as figure 2 As shown, a charging circuit includes: catenary power supply 1, first power supply in the library 2, energy storage unit 3, grounding unit 4, first switch unit 5, second switch unit 6, third switch unit 7, the first Four switching units 8, pre-charging unit 9, capacitor 10, DC / DC unit 11 and DC / AC unit 12; the catenary power supply 1 is connected to one end of the first switching unit 5, and the first switching unit 5 The other end of the pre-charging unit is connected to one end of the pre-charging unit and one end of the second switch unit 6, and the other end of the pre-charging unit is connected to one end of the capacitor 10 and the first positive pole of the DC / DC unit 11 The input end is connected, the second positive input end of the DC / DC unit 11 is connected to the first end of the DC / AC unit 12, and the second end of the DC / AC unit 12 is connected to the third switch unit 7 The other end of the third switch unit 7 is connected to the power ...

Embodiment 2

[0049] A control device for controlling the charging circuit described in Embodiment 1, comprising a first control unit, the first control unit is used for:

[0050] When using catenary power supply for charging, close the first switch unit and the sixth switch unit; when the capacitor voltage reaches the preset value U1, open the sixth switch unit and close the fifth switch at the same time unit;

[0051] When using the first internal power supply for precharging, close the sixth switch unit; when the capacitor voltage reaches a preset value U2, open the sixth switch unit and simultaneously close the third switch unit;

[0052] When using the second internal power supply for precharging, the sixth switch unit is turned on; when the capacitor voltage reaches a preset value U2, the sixth switch unit is turned off and the seventh switch unit is turned on at the same time.

[0053] Thus, automatic control of the charging circuit in Embodiment 1 can be realized.

Embodiment 3

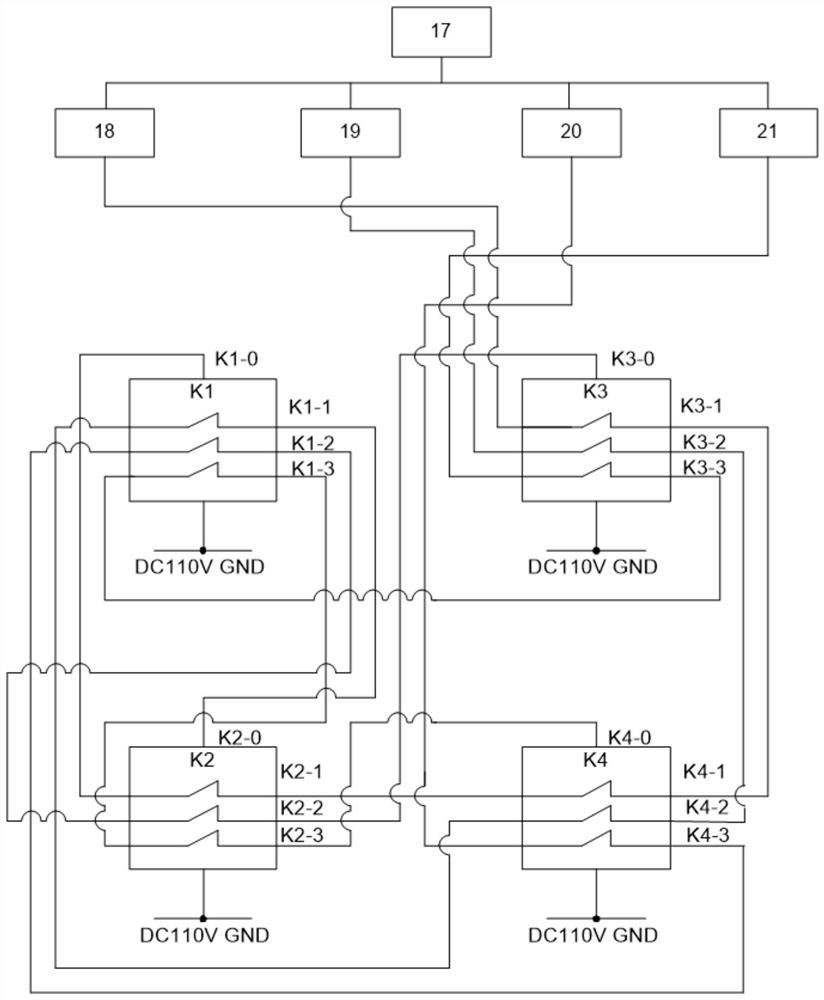

[0055] Such as image 3 As shown, the control device of this embodiment further includes on the basis of the control device of embodiment 2: a second control unit 17, a first control switch 18, a second control switch 19, a third control switch 20, a fourth control switch 21. The first contactor K1, the second contactor K2, the third contactor K3 and the fourth contactor K4;

[0056] The first contactor K1 includes a first main contact terminal, a first coil terminal K1-0, a first auxiliary normally closed contact terminal K1-1, a second auxiliary normally closed contact terminal K1-2 and a third auxiliary Normally closed contact terminal K1-3; the second contactor K2 includes a second main contact terminal, a second coil terminal K2-0, a fourth auxiliary normally closed contact terminal K2-1, a fifth auxiliary normally closed contact The point terminal K2-2 and the sixth auxiliary normally closed contact terminal K2-3; the third contactor K3 includes the third main contact t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com