Preparation process of fresh whitening toothpaste

A preparation process and technology for toothpaste, which is applied in the field of fresh whitening toothpaste preparation process, can solve the problems of high cost, easy deformation, and reducing the appearance of toothpaste packaging, so as to achieve the effect of increasing production cost and improving packaging efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

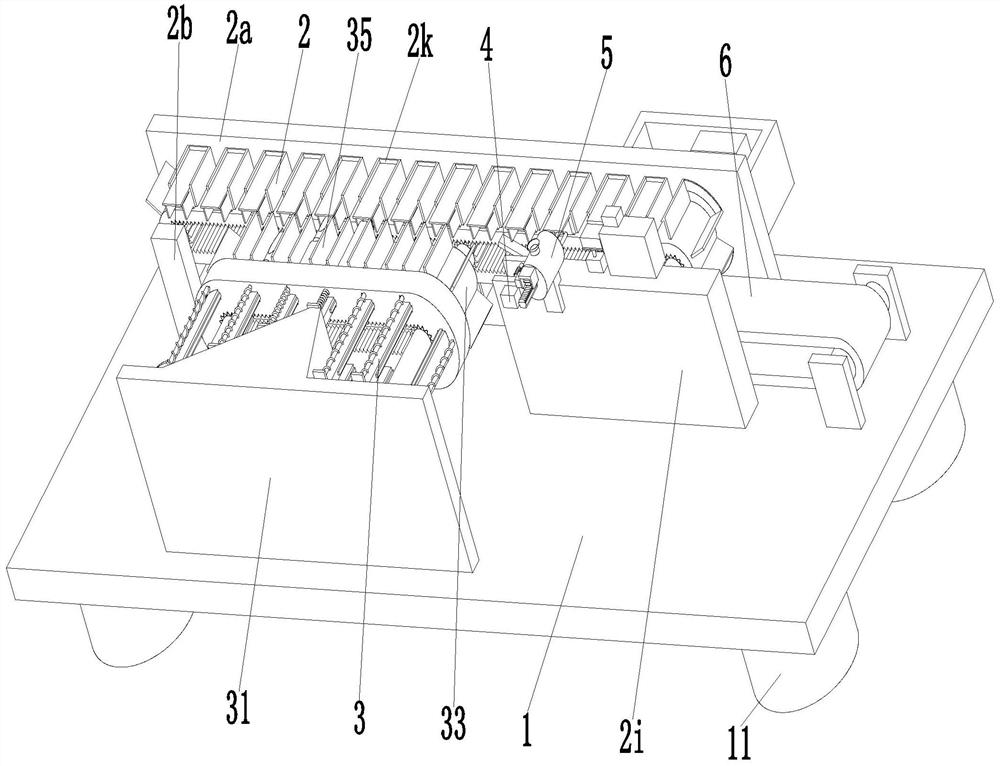

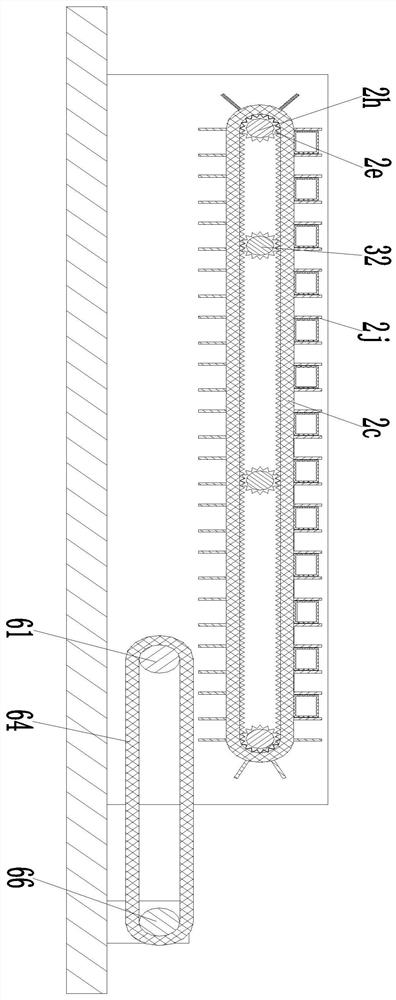

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

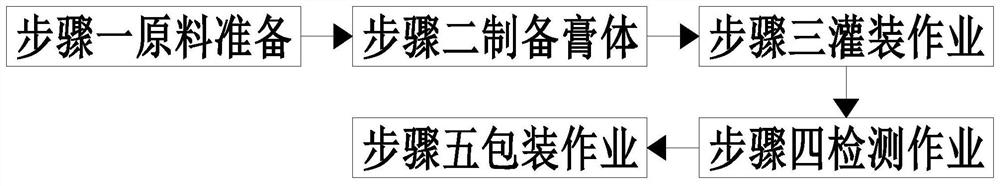

[0036] Such as Figure 1 to Figure 9 Shown, a kind of pure and fresh whitening toothpaste preparation technology mainly comprises the following steps:

[0037] Step 1, raw material preparation, prepare the raw materials needed for the production of fresh whitening toothpaste, and obtain the raw materials for toothpaste production;

[0038] Step 2, preparing paste, stirring and mixing the raw materials for toothpaste production obtained in step 1, to obtain a uniformly stirred paste;

[0039] Step 3, filling operation, performing filling operation on the evenly stirred paste obtained in step 2, to obtain filled toothpaste;

[0040] Step 4, detection operation, the filling finished toothpaste obtained in step 3 is carried out detection operation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com