Prefabricated UHPC slope anchoring plate device and mounting method thereof

An installation method and an anchoring plate technology, which are applied in excavation, coastline protection, construction, etc., can solve the problems of not being able to apply prestress immediately, low construction safety, and limited prestress application, so as to avoid structural instability and strengthen the anchoring effect , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

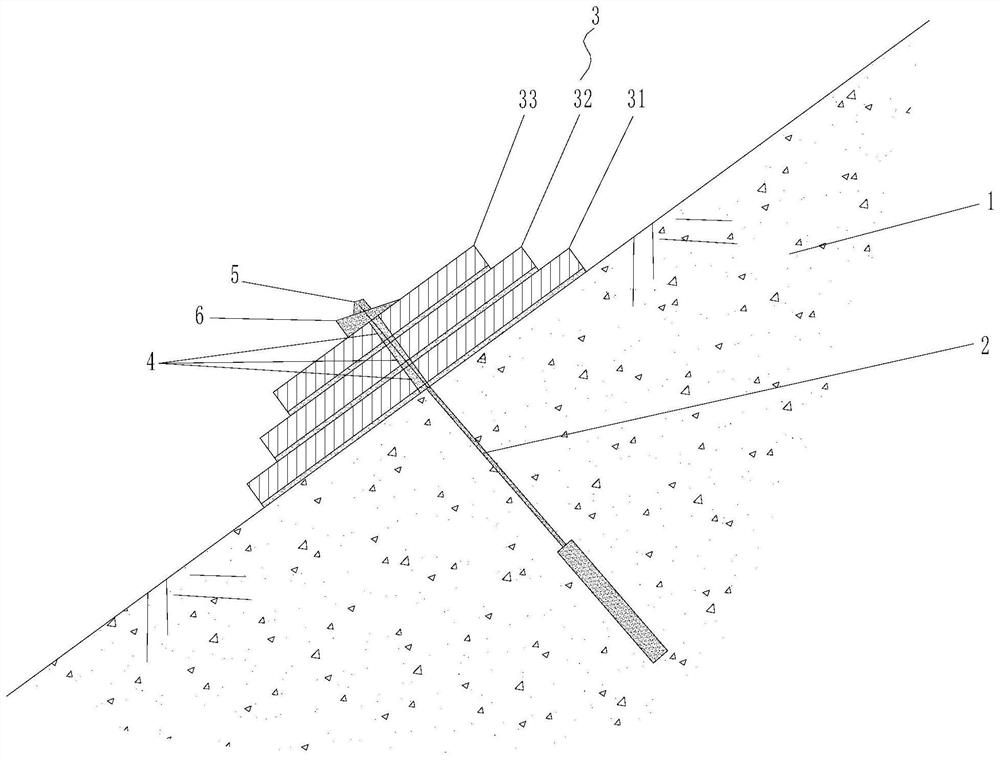

[0046] like figure 1 or figure 2 As shown, this embodiment is a prefabricated UHPC slope anchoring plate device, which is fixed with the anchor cable 2 pierced on the slope 1 and used to assist in fixing the slope 1. It includes N anchor plates arranged in sequence 3, and N is greater than 1, the centers of the N pieces of anchor plates 3 are all provided with first installation through holes 4, and the centers of the first installation through holes 4 on the N pieces of anchor plates 3 are all located on the same virtual axis. The anchor plate on the bottom layer is used to stick to the surface of the slope 1, and the tail ends of the anchor cables 2 pass through the first installation holes 4 of the N anchor plates 3 in sequence and are fixedly connected to the anchor plate on the uppermost layer through the anchor pier 5 , N pieces of anchor plates 3 are restrained and fixed on the slope 1. In this embodiment, anchoring concrete 6 is also provided between the anchor pier ...

Embodiment 2

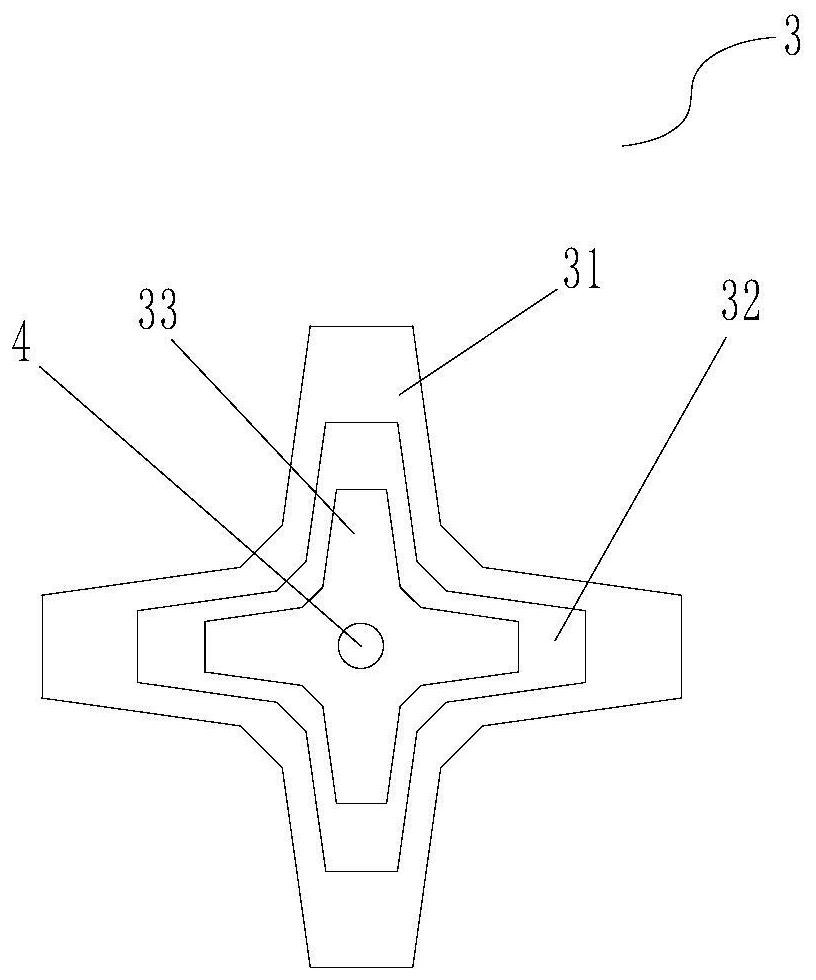

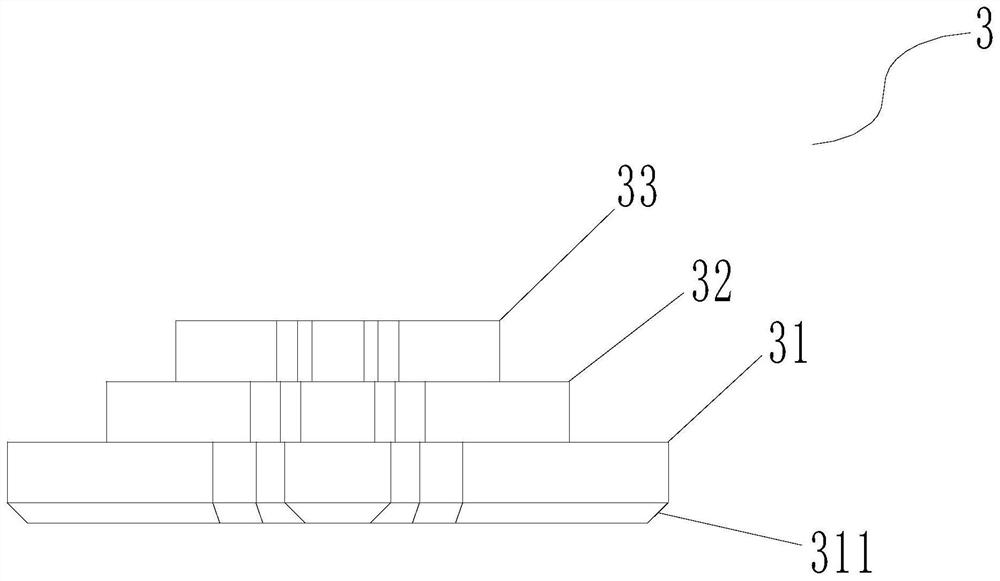

[0058] like Figure 3 to Figure 10 As shown in one, this embodiment is roughly the same as Embodiment 1, the difference is that, as a preferred implementation mode, preferably, the first anchoring plate 31 and the second anchoring plate 32 described in this embodiment There are oblique chamfers 311, 321, 331 between the lower end surface of the third anchor plate 33 and the corresponding side surfaces, and the chamfered side lengths of the oblique chamfers 311, 321, 331 are 1-2 cm. The angle of the acute angle formed by the angle 311, 321, 331 and the lower end surface of the first anchor plate 31, the second anchor plate 32 or the third anchor plate 33 is 30 degrees to 60 degrees, preferably 45 degrees. The upper end surface of the anchor plate 31 corresponds to the lower profile of the second anchor plate 32 and is provided with a first profiling accommodation groove 312 that cooperates with the second anchor plate 32. The depth of the first profiling accommodation groove 31...

Embodiment 3

[0068] like Figure 11 to Figure 17 One shows that this embodiment is roughly the same as Embodiment 2, and the difference is that, as a preferred implementation mode, preferably, this embodiment also includes several constraining screws 8 and several guide screw sleeves 7. The cross-shaped structures of the first anchor plate 31, the second anchor plate 32, and the third anchor plate 33 are provided with two pairs of second installation through holes 313, 323, 332 opposite to each other and running through the upper and lower end surfaces thereof The second installation through-holes 313, 323, 332 are obliquely opened from top to bottom towards the end direction corresponding to the first anchor plate 31, the second anchor plate 32 or the third anchor plate 33, and the first anchor plate 31, After the second anchor plate 32 and the third anchor plate 33 are stacked, the holes of the second installation holes 313, 323, and 332 located at the same end of the corresponding cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com