Particle circulating burner for biomass gasification combustion

A particle recycling and biomass technology, applied in gas fuel burners, burners, combustion methods, etc., can solve the problems of poor thermal efficiency, low combustion efficiency, large heat loss, etc., to reduce heat dissipation loss, low combustion temperature, flame retardant full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

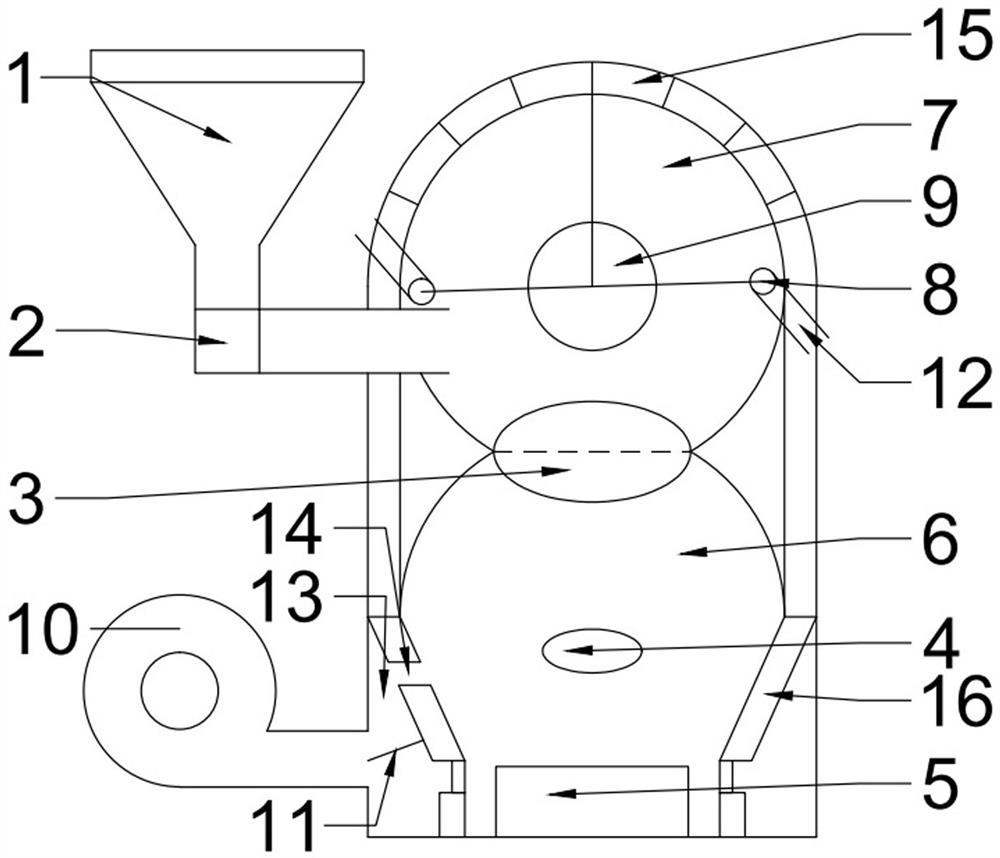

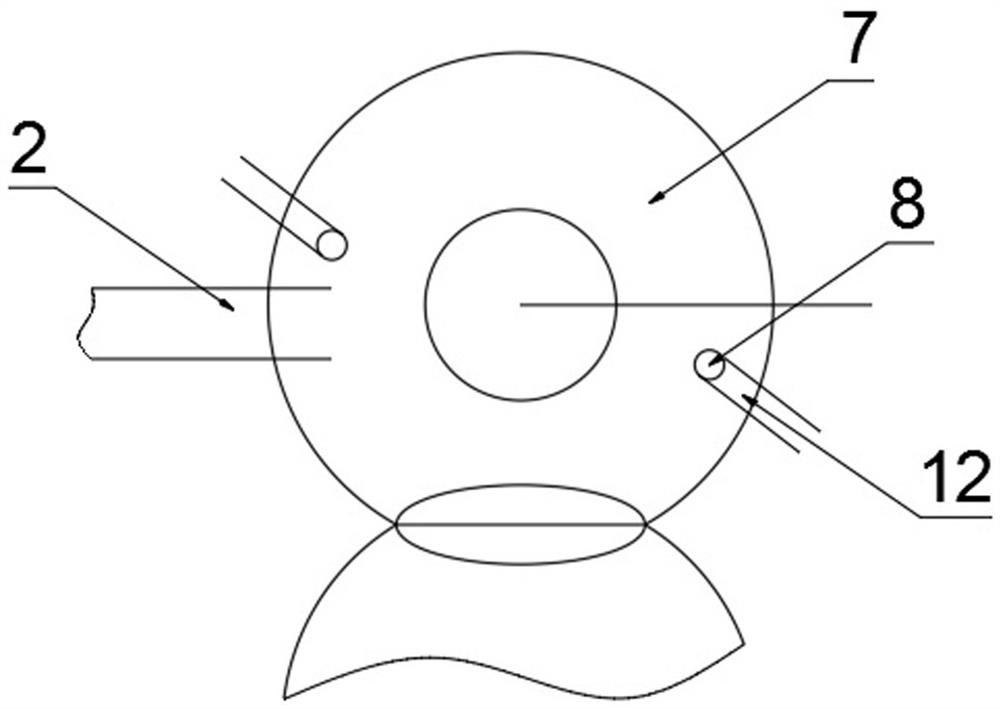

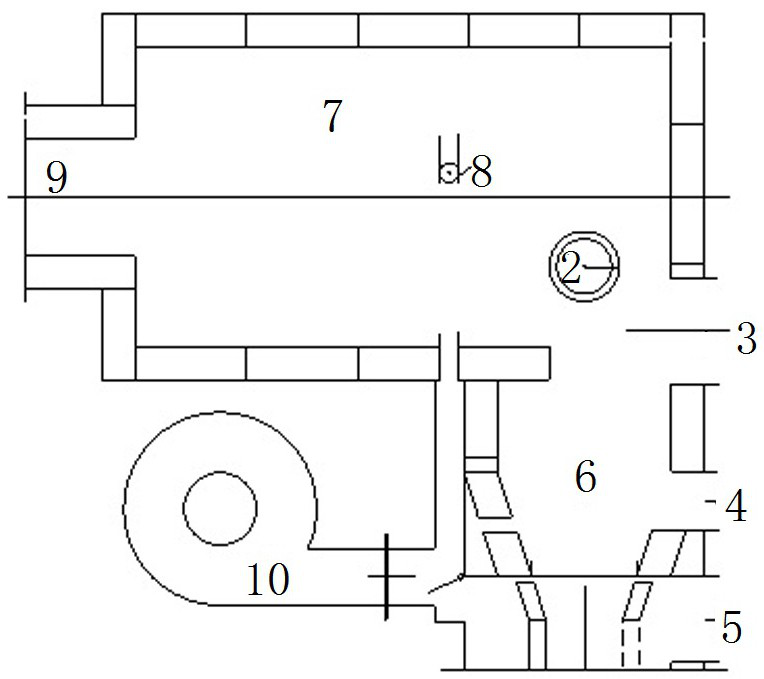

[0015] like Figure 1-3 As shown, the present invention provides a particle circulation burner for biomass gasification combustion. Its structure is divided into a cyclone high-temperature combustion zone and a low-temperature gasification zone, and the cyclone high-temperature combustion zone is arranged above the low-temperature gasification zone; the cyclone high-temperature combustion zone One side of the zone is connected to the granular fuel hopper through a horizontal pipeline, and the outlet of the constant-velocity feeder communicates with the inside of the cyclone high-temperature combustion zone inside the cyclone casing.

[0016] The inner side of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com