Container ship guide frame digital simulation test box method

A container ship and container technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as potential safety hazards, poor guide frame accuracy, and container stuck in high altitude, so as to reduce crane load and reduce Test box time, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

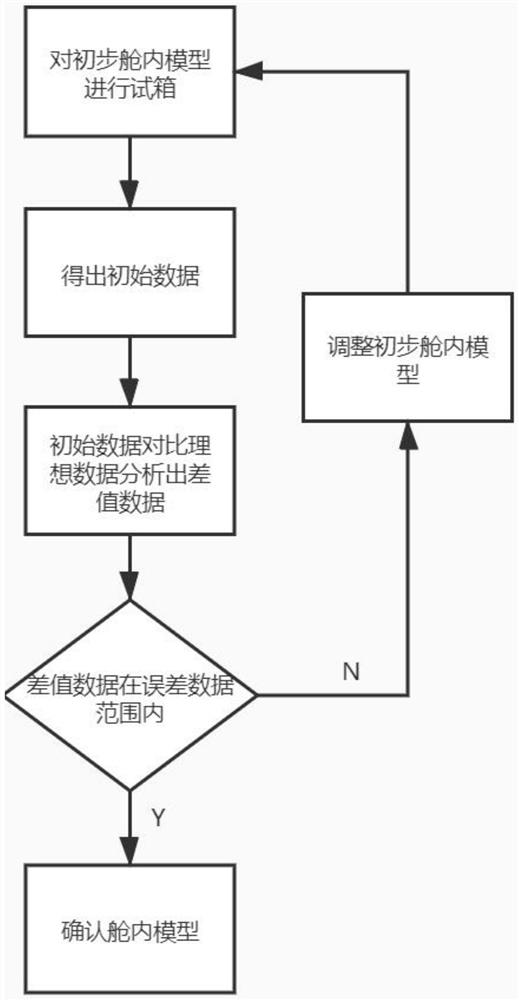

[0026] During the construction of container ships, the dimensional accuracy of container positions directly affects the efficiency and safety of container loading and unloading during ship operation. Therefore, it is a key control process for shipowners to inspect the container size before the container ship is put into operation. To improve the efficiency of the test box, the first thing is to control the accuracy of the guide frames. Before the test box, all the accuracy problems of the guide frames are closed to ensure that the container slides smoothly to the bottom of the bilge through the gap between the two guide frames during the test box. The solution of the invention is to digitize the test chamber process, simulate the test chamber by means of digital modeling, shorten the actual operation time and improve safety.

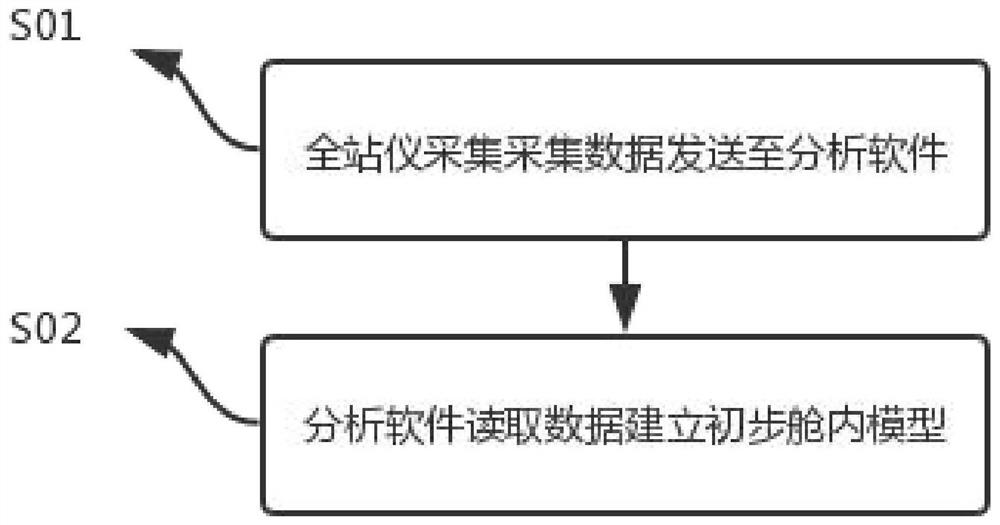

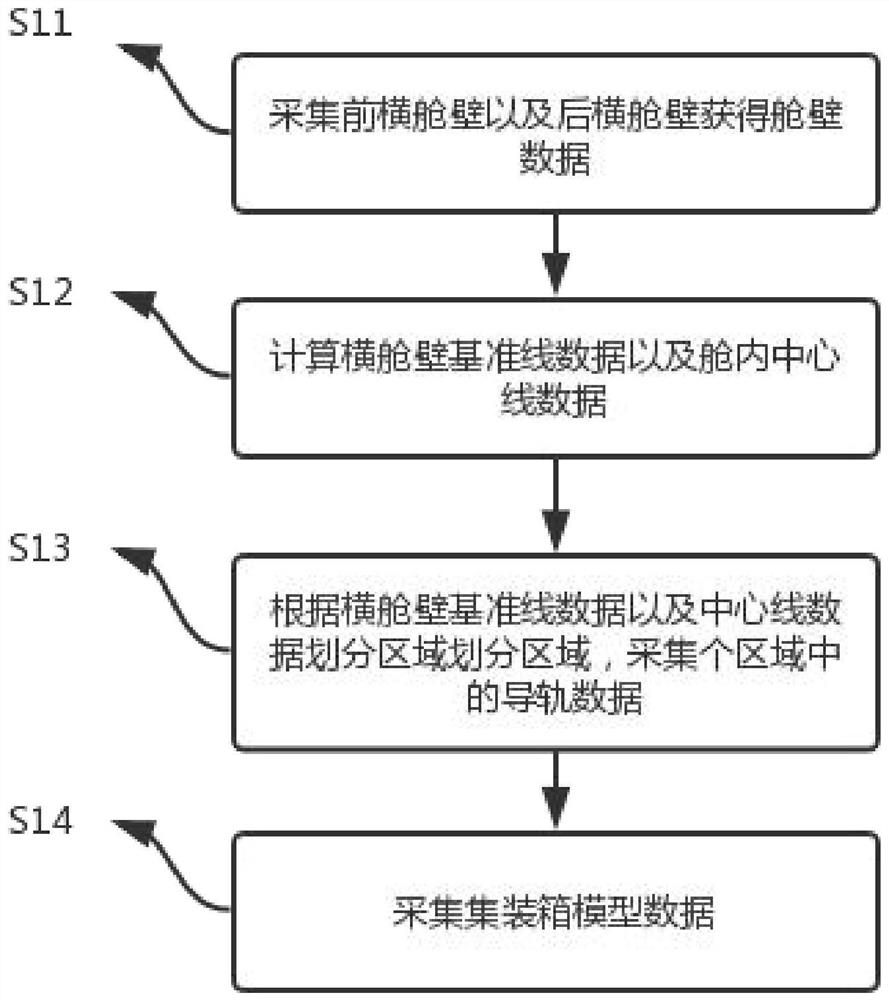

[0027] Such as figure 1 As shown, a container ship guide frame digital simulation test method, import several container models into the preliminary cab...

Embodiment 2

[0036] Such as Figure 5 As shown, a container ship guide frame digital simulation test box device of a container ship guide frame digital simulation test method includes a cabin 1, a guide frame 2 and a container 3; the guide frame 2 is located on the inner side wall of the cabin 1 transverse cabin; 3 slides along the guide frame 1 into the cabin 1; the bottom of the cabin 1 is also provided with an adjustment backing plate 11 that matches the container 3.

[0037]Preferably, the acquisition unit is used to collect cabin data and guide frame data in the cabin, adjust backing plate data, box cone data and container data; the calculation unit is used to calculate cabin data and guide frame data in the cabin, adjust backing plate data and The logical relationship between the container data; the feedback unit is used to feed back the cabin data and the guide frame data in the cabin, adjust the logical relationship between the backing plate data and the container data, and export ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com