Bubble acoustic metamaterial

A technology of acoustic metamaterials and bubbles, applied in the field of acoustic metamaterials, can solve problems such as low-frequency noise is difficult to effectively isolate, and achieve the effects of improving sound insulation, layout efficiency and overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

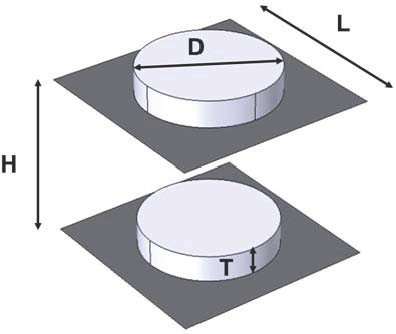

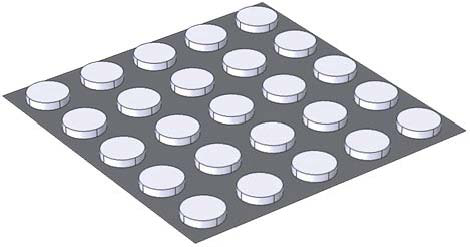

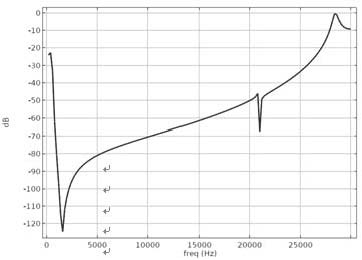

[0040] A circular air bubble film is selected as a frame structure with a periodic structure, and the material of the circular air bubble film is polyester. The air bubbles are arranged in a square arrangement, and the thickness of the air bubble film is 0.1mm. figure 1 is the geometric parameter map of the bubble acoustic metamaterial. figure 2 A top view of a tetragonal array of circular bubble films. Will figure 2 The shown bubble film is folded and heat-press sealed into a pocket, and filled with glycerol to make the bubble acoustic metamaterial. Its properties are: H (thickness of bubble acoustic metamaterial) is 24 mm, L (interlayer spacing of bubble film) is 30 mm, D (bubble diameter) is 20 mm and T (bubble thickness) is 4 mm. The sound shielding effect of this bubble acoustic metamaterial was measured experimentally, and the simulated acoustic transmission spectrum obtained is as follows: image 3 shown. It has a sound shielding effect of more than 30dB in the r...

Embodiment 2

[0042] The elliptical bubble film is selected as the frame structure of the periodic structure, in which the bubbles are arranged in a square arrangement. The properties of the bubble film are: the material is polypropylene, the distance between the bubbles is 1 cm, and the number of bubbles per square decimeter of the bubble film is 20. Figure 4 A top view of a tetragonal elliptical bubble film.

Embodiment 3

[0044] The bubbles in the bubble film are arranged in a connected manner. The properties of the bubble film are: the material is polyethylene, the distance between the bubbles is 0.5 cm, and the number of bubbles per square decimeter of the bubble film is 30. Figure 5 is a top view of a membrane with interconnected bubbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com