Heater

A technology for heaters and cylindrical parts, applied in the direction of lamp circuit components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments will be described with reference to the drawings. In addition, in each drawing, the same code|symbol is attached|subjected to the same component, and detailed description is abbreviate|omitted suitably.

[0018] The heater according to this embodiment can be used to heat an object or a space in which the object is placed. Hereinafter, as an example, a heater required to have anti-glare property will be described. Heaters that require anti-glare properties can be used, for example, as heating equipment for heating spaces such as stores. However, the heater according to this embodiment can also be applied to heaters that do not require anti-glare properties. That is, the heater according to this embodiment can also be applied to a heater not provided with a film described later.

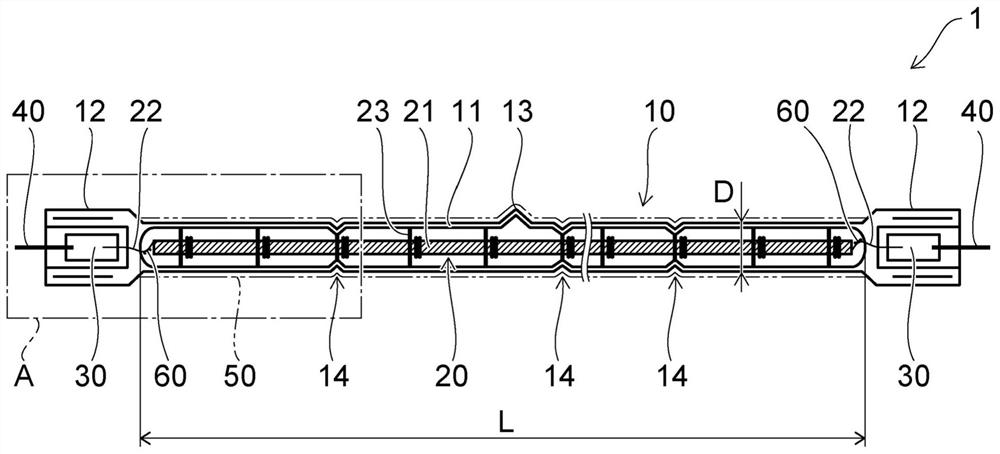

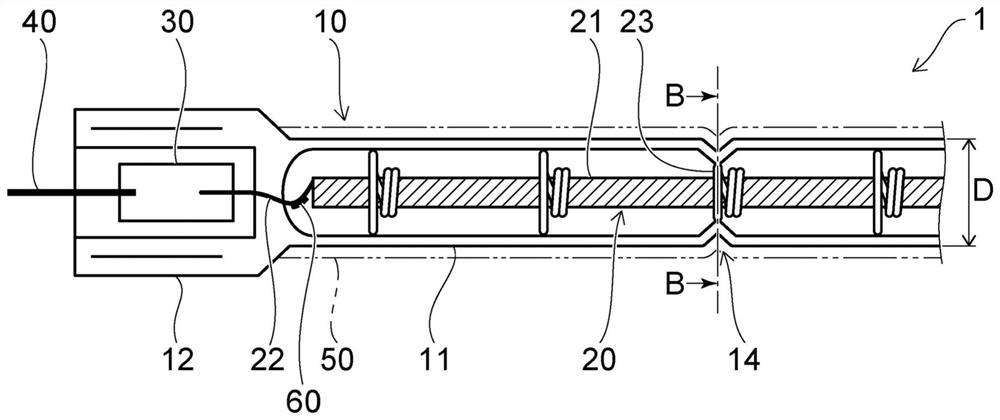

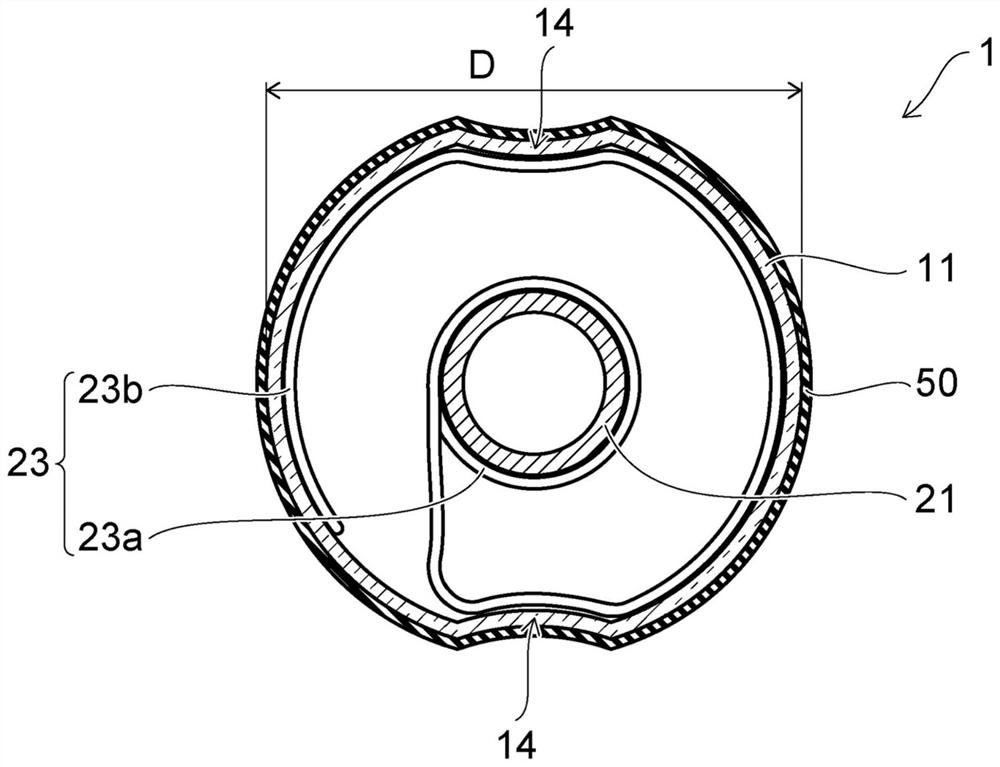

[0019] figure 1 It is a schematic diagram for illustrating the heater 1 which concerns on this embodiment.

[0020] figure 2 yes figure 1 Schematic enlarged view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com