Squeezing device for bamboo juice production

A technology of bamboo juice and main casing is applied in the field of extracting devices for bamboo juice production, and can solve the problems of aggravating the processing operation of bamboo juice, affecting the extraction of bamboo juice, and rough breaking of bamboo.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

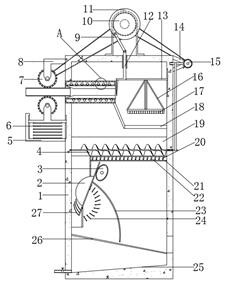

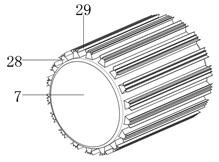

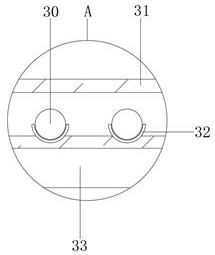

[0029] refer to Figure 1-4 , a kind of squeezing device for bamboo juice production, comprising a main housing 1, the inner bottom of the main housing 1 is set as an inclined bottom end 25, and one side of the main housing 1 is provided with a feeding mechanism, and the feeding mechanism includes welding parts respectively welded to the main housing. The fixed bracket 8 and the fixed bracket 5 on one side of the housing 1 are welded with a compression spring 6 at the inner bottom of the fixed bracket 5, and the end of the compression spring 6 is welded with a sliding connection with the fixed bracket 5 and the main housing 1. The sliding frame, the sliding frame and the fixed frame 8 are all connected to the feed roller 7 through the bearing rotation, and the circumferential outer wall of the feeding roller 7 is welded with convex rods 28 distributed equidistantly, and the outer walls of the convex rods 28 are welded with symmetrically distributed The metal sheet 29, the end ...

Embodiment 2

[0039] refer to Figure 5 , a kind of extracting device for bamboo juice production, the present embodiment also includes that the inner wall of the conveying chamber plate 19 is provided with a cavity 22, and the inner wall of the cavity 22 is fixedly equipped with a reciprocating corrugated heating wire 20, and the conveying chamber plate 19 is close to the screw extrusion One side of the twisted rod 4 is welded with equidistantly distributed outer protruding rods 34, and the end side of the outer protruding rods 34 is an arc surface; the setting of the outer protruding rods 34 can effectively increase the heating area of the conveying cavity plate 19, thereby packaging The heating effect of bamboo blocks.

[0040] When the present invention is in use: control and start the reciprocating corrugated heating wire 20, which can cooperate with the outer convex rod 34 to effectively heat the conveying chamber plate 19, and the rotation of the screw extruding twisted rod 4 makes...

Embodiment 3

[0042] refer to Figure 5 , a extracting device for bamboo juice production, the present embodiment also includes that the side of the cavity 22 away from the outer convex rod 34 is provided with a thermal insulation layer 21, and the outer convex rods 34 are all provided with inner strip grooves 35 distributed equidistantly.

[0043] When the present invention is in use: the surface area of the outer convex rod 34 can be increased by setting the inner bar groove 35 and the insulation layer 21 arranged on the outer convex rod 34, thereby improving the auxiliary heating effect on the bamboo block and ensuring the subsequent juice extraction effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com