Orthopedic composite adhesive material and preparation method thereof

An adhesive material and orthopedic technology, applied in the field of medical materials, can solve the problems of poor antibacterial performance and achieve the effect of enhanced antibacterial performance, high biological safety, and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

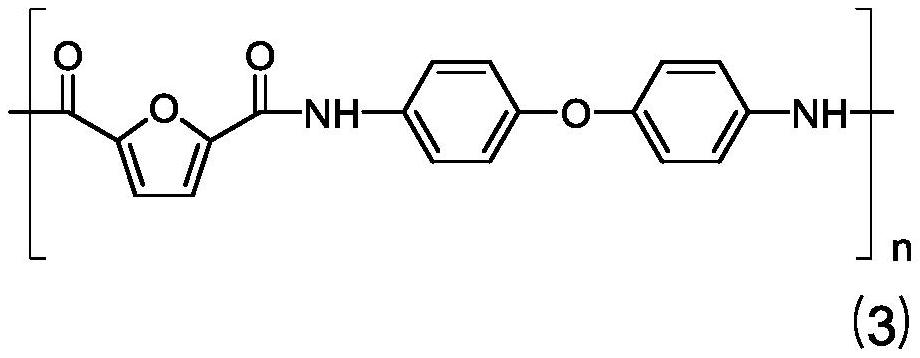

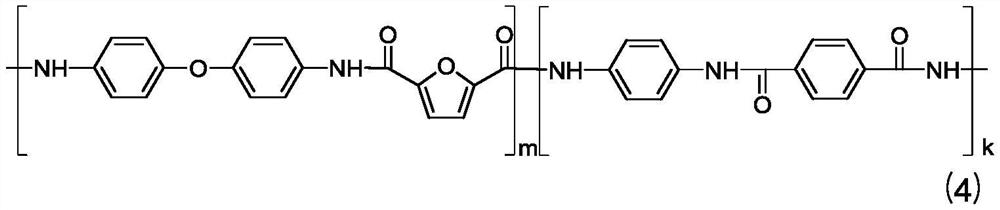

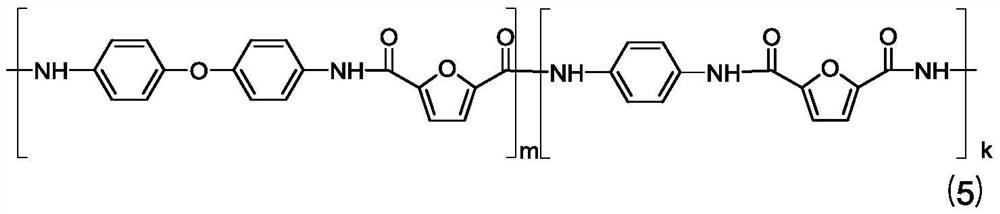

Embodiment 1

[0045] The orthopedic composite adhesive material includes a solid component and a liquid component, and the mass ratio of the solid component to the liquid component is 2:1. Solid components include 16.2g polymethyl methacrylate (90wt%), 1.8g furyl aromatic polyamide powder (10wt%), 2g barium sulfate (BaSO 4), 0.1g benzoyl peroxide (BPO); liquid components include 10mL methyl methacrylate, 50uL N,N-dimethyl-p-toluidine (Dmpt), furyl aromatic polyamide powder used in this embodiment The publication number is the high molecular weight furan-based polyamide in Example 1 of the patent application specification CN110256668A. Among them, barium sulfate is used as a contrast agent, which plays a contrasting role, and benzoyl peroxide belongs to an initiator, which is used to initiate a second polymerization reaction during use. N,N-Dimethyl-p-toluidine catalyzes BPO to generate free radicals, which belongs to the activator. The molecular weight of polymethyl methacrylate in this e...

Embodiment 2

[0051] The difference between this example and Example 1 is that the mass of polymethylmethacrylate is 17.1g (95wt%), and the mass of furyl aromatic polyamide powder is 0.9g (0.05wt%).

[0052] At a temperature of 23°C and a humidity of 40%, it was left to stand for 3 minutes and then cured for 10 minutes to obtain a bioactive and antibacterial orthopedic medical composite adhesive material.

Embodiment 3

[0054] The difference between this example and Example 1 is that: the orthopedic medical composite adhesive material with bioactivity and antibacterial properties was obtained after standing for 3 minutes at a temperature of 21° C. and a humidity of 60% and then cured for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com