Encapsulation method of composite reinforced wall plate axial compression test piece

A technology of reinforced wallboard and axial compression test, which is applied in the preparation of test samples, etc., to avoid excessive temperature of the glue, uniform heat distribution, and improve the quality of the potting glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

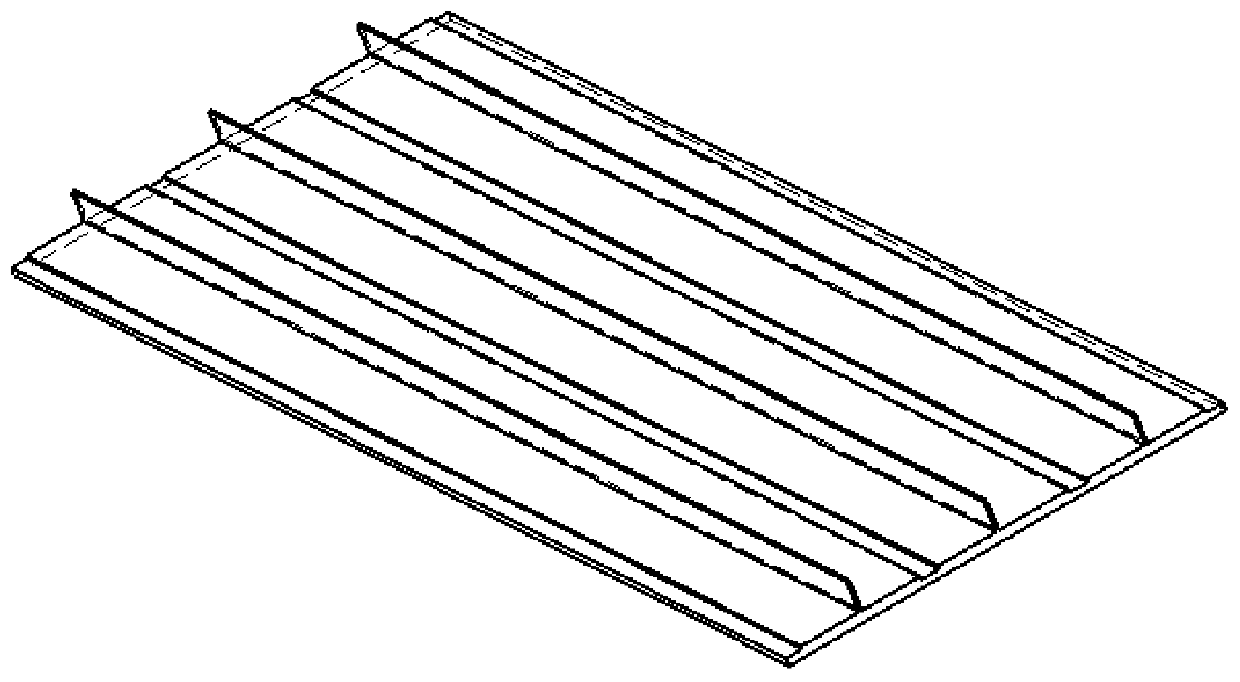

[0040] According to the above steps, the material of the composite material reinforced wall panel axial compression test piece 1 in this embodiment is M21C resin prepreg, such as figure 1 As shown, the sandpaper used is Panda 120 mesh, the potting glue used is DG-3, and the quartz sand used is 200 mesh.

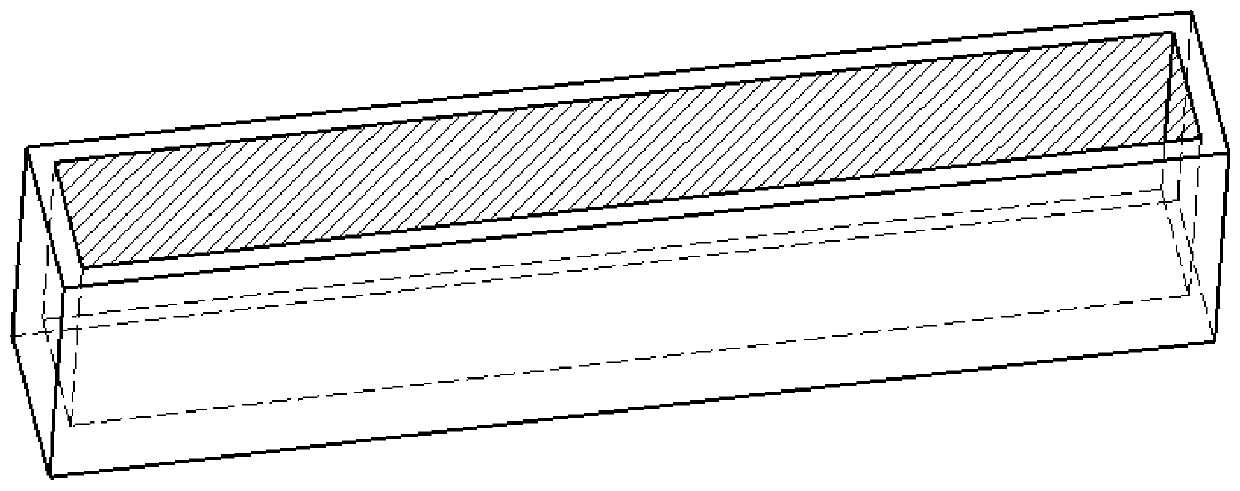

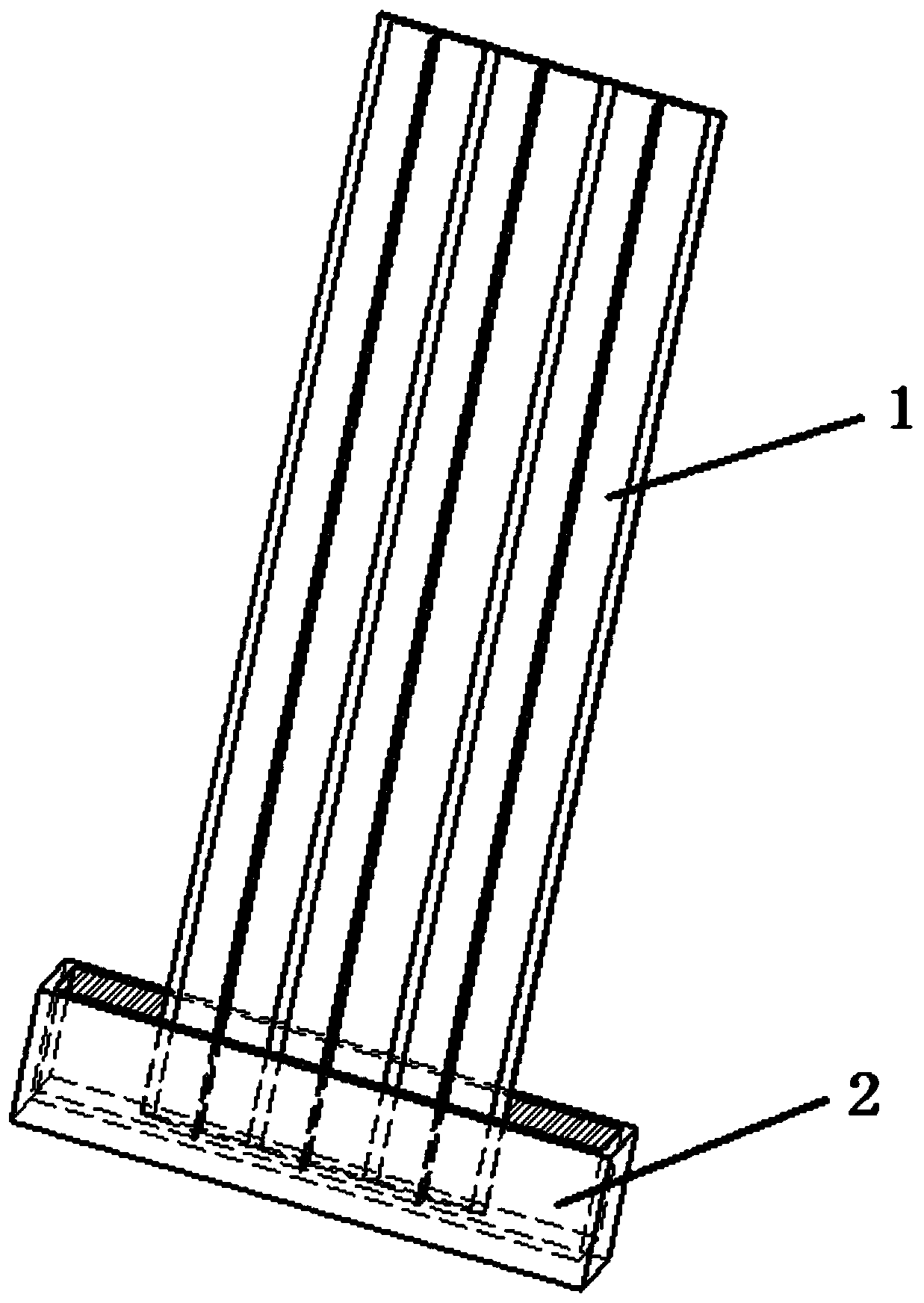

[0041] First, draw a line at the two ends of the composite material reinforced wallboard axial compression test piece 1 where the glue potting box 1 is inserted, and use Panda 120 mesh sandpaper to polish off the resin on the surface of the test piece without damaging the fibers. DG- 3. Pour the main agent components into the container for heating, and fully stir during the heating process; add 200 mesh quartz sand into the container, and then fully stir; after stirring evenly, add the curing agent component, and fully stir; Add the proportioned glue in the container to the glue filling box 1, such as figure 2 As shown, put one end of the composite material reinforced wallb...

Embodiment 2

[0043] According to the above steps, the material of the composite material reinforced wall plate axial compression test piece 1 in this embodiment is X850 resin prepreg, such as figure 1 As shown, the sandpaper used is Panda 120 mesh, the potting glue used is J-133, and the quartz sand used is 200 mesh.

[0044] First, draw a line at the two ends of the composite material reinforced wallboard axial compression test piece 1 where it is inserted into the glue box 1, and use Panda 120 mesh sandpaper to polish off the resin on the surface of the test piece without damaging the fibers. Pour the main agent component of 133 into the container; add 200 mesh quartz sand into the container, and then fully stir; after stirring evenly, add the curing agent component, and fully stir; add the glue solution in the container to the potting box 1, such as figure 2 As shown, put one end of the composite material reinforced wallboard axial compression test piece into the glue filling box 1 fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com