Structure for improving rigidity of offset type swing angle milling head

A technology of rigidity and milling head, which is applied in the field of the rigidity improvement structure of the offset swing angle milling head, and can solve the problems of affecting the machining quality of the workpiece, the swing angle error of the swing shaft, and increasing the deformation of the rotating shaft assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A structure for increasing the stiffness of the offset pendulum milling head proposed by the present invention will be described in detail in conjunction with the accompanying drawings.

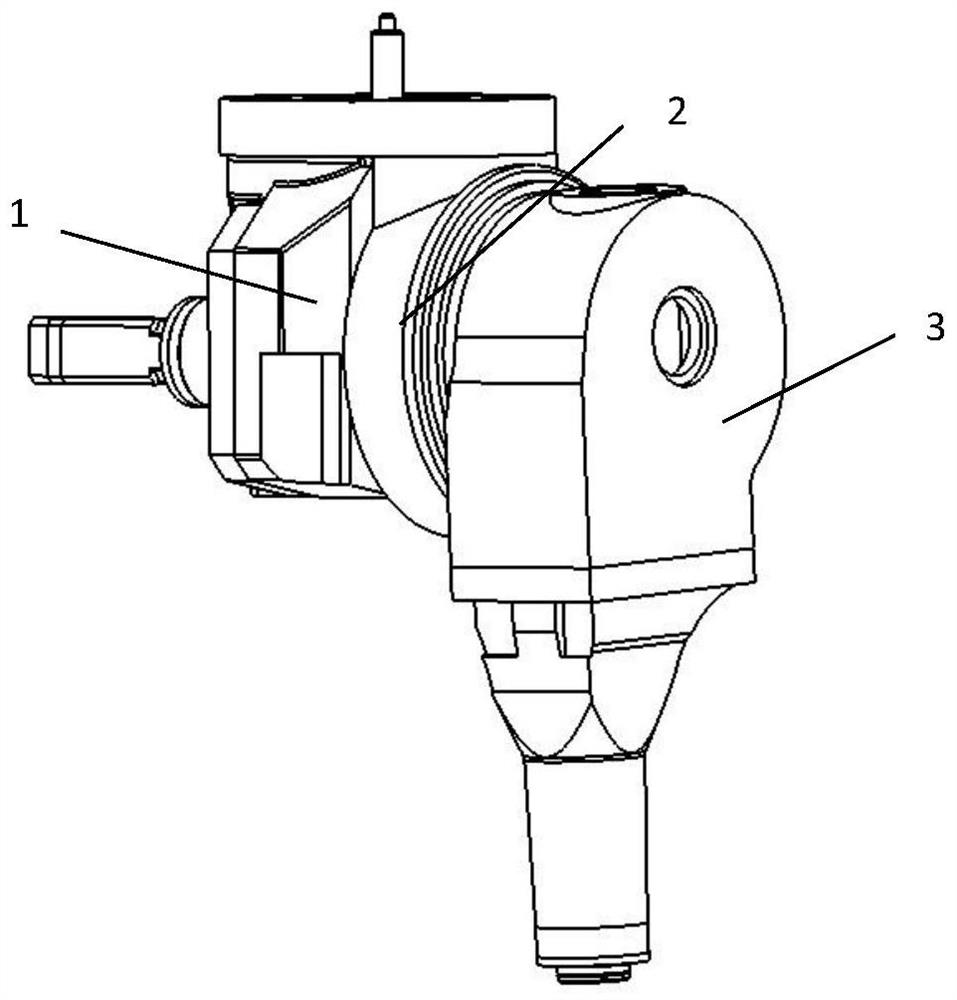

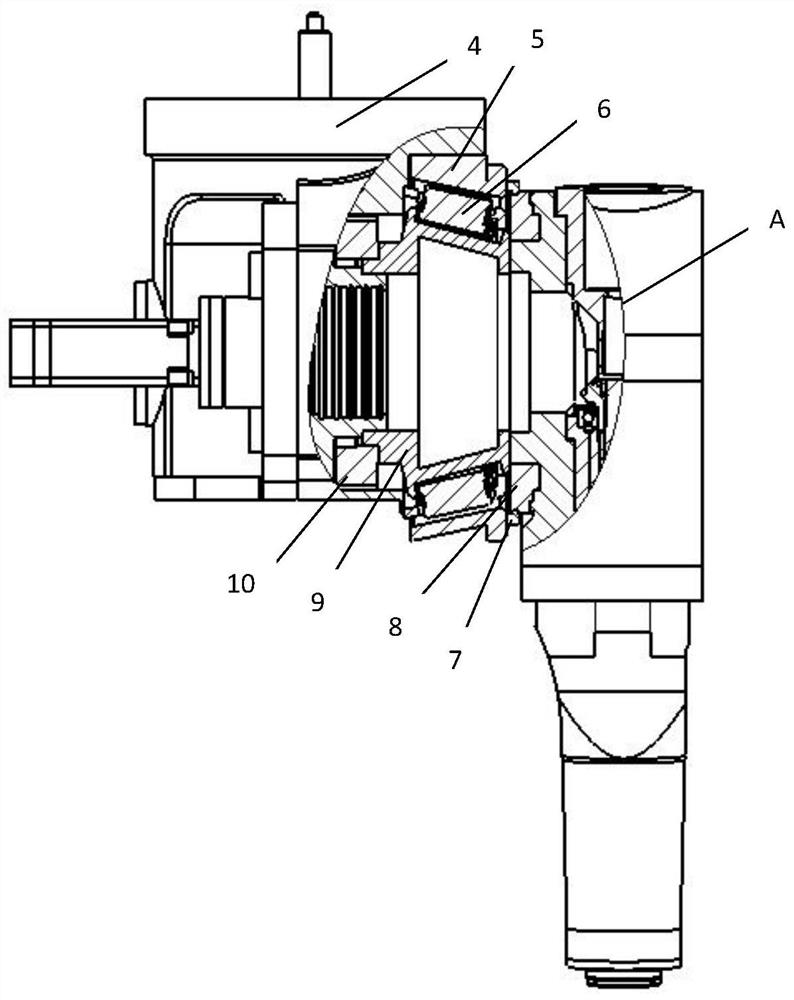

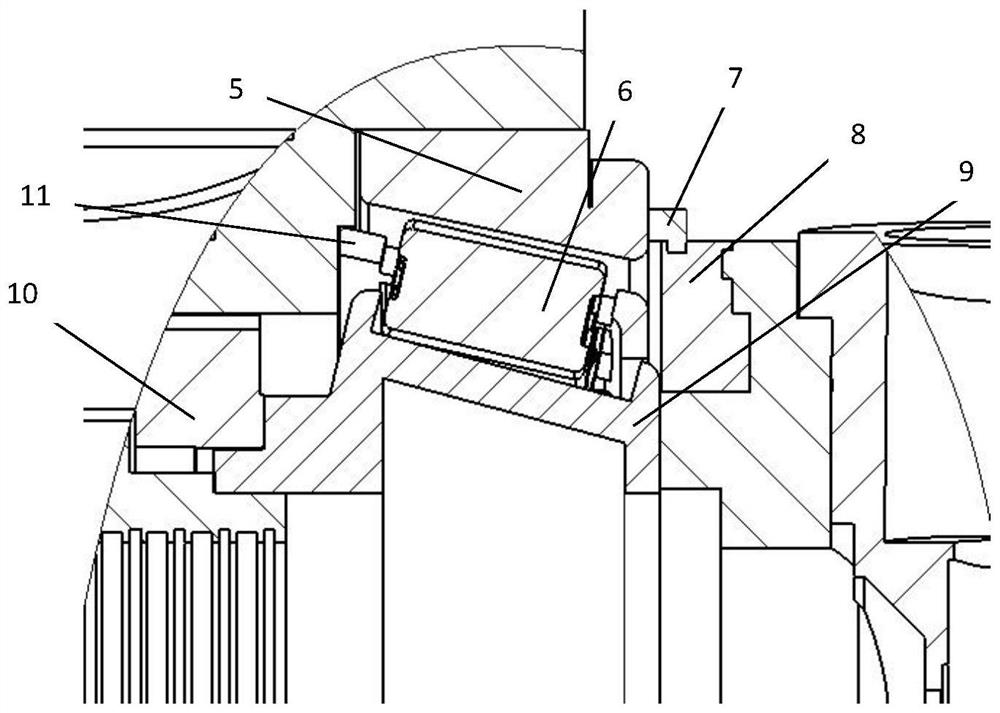

[0022] figure 1 It is a structural schematic diagram of the offset type pendulum angle milling head in the present invention, figure 2 for figure 1 Partial cross-sectional view of the milling head shown in , as figure 1 and figure 2 As shown, the swing angle milling head rigidity raising structure 2 is installed between the rotating shaft assembly 1 and the swinging shaft assembly 3, and the swing angle milling head stiffness raising structure 2 includes an inner ring rotating assembly, an outer ring fixed housing 5 and a sealing sleeve The ring assembly, the inner ring rotation assembly includes rolling elements 6, the rotation inner ring 9, and the cage 11. One side of the rotation inner ring 9 is fixed to the swing shaft gear 10 by screws, and the other side is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com